NaN / 0

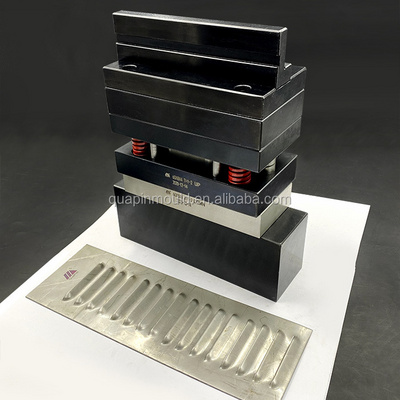

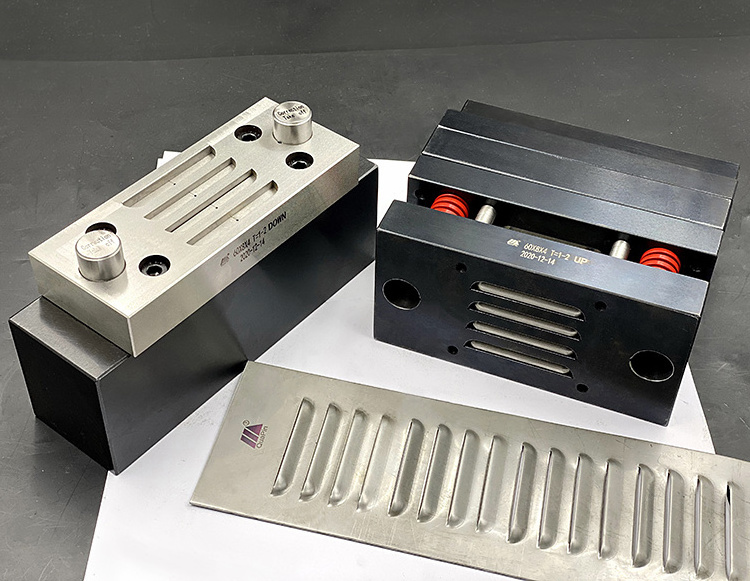

CNC press brake tooling Louver Forming die Bending machining Sheet metal 60*8mm*4 holes

Get Latest Price

US$ 750

≥1 Sets

Quick Details

Shaping Mode:

Punching Mold

Place of Origin:

Guangdong, China

Brand Name:

quapin

Model Number:

amada

Product Details

Bending mold details

| Material | 42CrMo |

| Hardness | 45-50HRC |

| Option | Black-antirust |

| Standard |

Segmented, Arc, International Standard, Three Point, Non-Streaking, Adjustable Groove, Special, etc

|

| Delivery time | 5 - 10 Days |

|

Model Number

|

Large machetes, special custom gooseneck type, straight-edged swords, single V lower die, double-folded upper and lower die; Flanged side avoidance bent upper die, same core 2V rail fixed standard lower die, R round-arc roller fold Bending die, 2V bolt-fixed standard lower die, 1V slot standard lower die, 1V thick panel corner bend lower die, excellent gel lower die, multiple V lower die, various die seats, seamless bending Module, segment differential mode combination, etc |

Product Description

Bending mold orderin

According to the different requirements of customers, choose the best mold design program, with the fastest time, the best quality to meet customer requirements. In addition, if you have difficulties in selecting a mold, please contact our company. Please provide the following:

1. Detailed shape of the general shape of the finished product and the bent portion (bending radius, inner contour size, tolerance range, etc.)

2. Material, thickness

3. Requirements for scratches (injuries)

4. Machine used for bending (machine model, maximum tonnage, table length)

5. Others, especially need to specify matters.

Upper die interface category:

| European - Amada | TruBend - Wera | LVD | Beyeler - Bys Xpert |

CNC bending tool segmentation, regular segment specifications are as follows:

Mold section 1

CNC bending on the mold: 100 (left), 10,15,20,40,50,200,300,100 (right) = 835mm

CNC bending lower die: 10, 15, 20, 40, 50, 100, 200, 400 = 835mm

Mold section 2

CNC bending on the mold: 100 (left), 10,15,20,40,50,165,300,100 (right) = 800mm

Production Process:

Down → Forging → Tempering → Finishing → Quenching → Annealing → Conditioning → Coarse Grinding → Finishing → Inspection → Packaging → Factory

Ordering Information:

1. the price and pictures are for reference only, due to the particularity of the products, different specifications, different materials, different technical requirements, prices and pictures are not the same, please be sure to explain the specification materials and requirements, leave the way to contact you, We will contact you in time to give you a quote.

2. When contacting with our customer service staff, please tell us if you have purchased other products from our factory. Our company has record records for all customers so that you can easily find your original order information and save your precious time.

3. In order to provide you with the required products, please provide the product specifications, models and machine specific manufacturers, individual precision products also require you to provide your drawings, pictures or samples.

4. standard parts we can be shipped within a week, non-standard parts of the cycle, according to your workpiece is difficult to set!

5. The price and the picture are for reference only. Actually according to the needs of the pro, different prices of materials of different specifications and materials are also different; the postage is also imaginary, and large-size products generally take the logistics.