NaN / 0

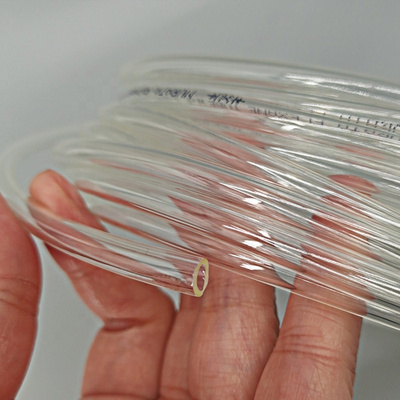

High Quality Flexible Food Grade Silicone Rubber Pipe/Extruded Silicone Rubber Hose

Get Latest Price

US$ 0.02

≥100 Pieces

Quick Details

Place of Origin:

Fujian, China

Brand Name:

SHEDL

Model Number:

SD089592DH

Standard or Nonstandard:

Standard

Product Details

Professional factory custom rubber hose

Product Description

|

Material

|

SILICONE, EPDM, NR, FKM, CR, NBR, SBR. etc

|

|

|

|

|||

|

Color

|

Black, green,brown based on customer's needs

|

|

|

|

|||

|

Size

|

As customers' requirements

|

|

|

|

|||

|

Hardness

|

shore A 30-90 according to work environment

|

|

|

|

|||

|

Service

|

OEM or ODM

|

|

|

|

|||

|

Production basis

|

Samples or drawings

|

|

|

|

|||

|

Technology

|

compression,molding, extrusion, etc

|

|

|

|

|||

|

Density

|

1.0-2.0g/cm³

|

|

|

|

|||

|

MOQ

|

100 pcs rubber hose

|

|

|

|

|||

|

Sample

|

Sample is free from stock

|

|

|

|

|||

|

Application

|

Mechanical equipment, Automotive,Construction, Home appliance, Aviation,Office facilities and so on

|

|

|

|

|||

|

Performance

|

1.Good sealing and damping

2.Water resistance 3.Anti-aging 4.Anti- ozone 5.oil-resistant 6.pressure resistant 7.High and low temperature resistant |

|

|

|

|||

|

EPDM

|

Good resistance to hot water and steam, detergents, caustic potash solutions, silicone oil and greases, many polar solvents, and many diluted acids and chemicals, along with a high level of ozone resistance. EPDM materials are totally unsuitable for use with all mineral oil products (lubricants, fuels).

|

|

|

|

|||

|

FKM

|

Good chemical resistance to mineral oils and greases, synthetic oils and greases, engine, transmission and ATF oils to approx. +150°C, fuels, non-flammable hydraulic pressure fluids HFD, aliphatic, aromatic and chlorinated hydrocarbons, water to max. +80°C, excellent resistance to weathering, ozone and ageing, very low gas permeability (and therefore excellent for vacuum application) and resistance to a wide range of chemicals.

|

|

|

|

|||

|

HNBR

|

HNBR is obtained by fully or partially hydrogenating NBR. It leads to considerable improvement in resistance to heat, ozone and ageing, and gives it very good mechanical properties, e.g. good resistance to wear. The media resistance compares to that of NBR. HNBR has a good resistance to some refrigerants. The temperature application range is from -30°C to +150°C.

|

|

|

|

|||

|

NBR

|

Good chemical resistance to mineral oils and greases, hydraulic oils H, HL, HLP, non-inflammable hydraulic pressure fluids HFA, HFB, HFC to approx. +50°C and water to max. +80°C

|

|

|

|

|||

|

VMQ

|

Good resistance to water (up to 100 °C), aliphatic engine and transmission oils, animal and plant oils and fats. VMQ is generally not resistant to fuels, aromatic mineral oils, steam (short term up to 120 °C possible), silicone oils and greases, acids and alkaline compounds.

|

|

|

|

|||

Packaging & Shipping

All rubber hose

w

ill be well packed before shipping. they will be shipped by sea, by air or by express delivery according to the weight, the quantity or as the customers' requirements.

Delivery Time

2 -7 days for samples

· 3-15 days for mass production

Our Company

We are a manufacture mainly specialize in producing different types of O-rings. O-ring repair kits, customized rubber products.The materials are available in SILICONE, FKM, EPDM, NBR, HNBR, SBR, CR and so on.

We have thousands of available O-ring moulds in stock and sample is free from our stock. We can also open new moulds as customers' drawings or physical sample for standard or non-standard O rings and other rubber parts.

Exhibition

Our Team

Certification

Testing Equipments

Raw Material

Our service

1.More than 10

years experience in manufacturing o rings

2. 2

-7 days fast sample delivery time.

3. We have our own import & export license

, OEM&ODM service are available.

4. ISO9001,ISO14001 and RoHS certificate are available.

5. We accept sample order, trial order and mix order.

FAQ

1. What is your MOQ ?

Usually our MOQ is 1000 pcs. But we accept small quantity for the first trial order.

2. Can I get sample ?

Sure. We usually provide existing sample for free. But a little sample charge for custom designs. Sample charge is refundable when order is up to certain quantity.

3.How long is the sample LEAD TIME?

For existing samples, it takes about 2 days. They are free. If you want your own designs, it takes 3-7 days, subject to your designs whether they need new printing screen, etc.

4. How long is the production lead time?

It takes about 15 days for MOQ.

5. How much is the freight charge?

To save cost for you and in order that you can get goods earlier, we suggest to deliver by express for small quantity. For large quantity, we suggest to deliver by sea.

6. What format of the file do you need if I want my own design?

We have our own professional designers. So you can provide JPG, AI, CDR or PDF, etc. We will draw artwork for mold or printing screen for you.

Hot Searches