NaN / 0

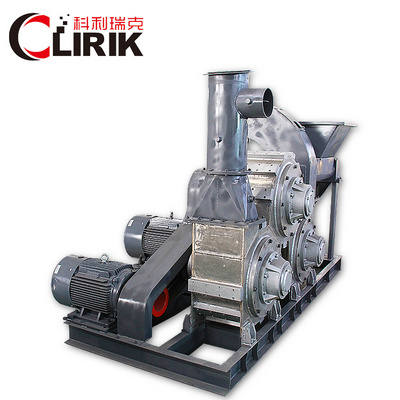

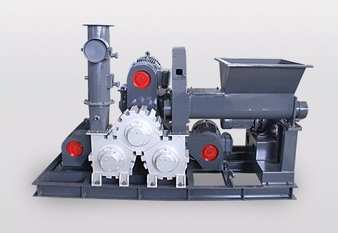

Calcium Carbonate Stearic Acid Reaction Milling Machine Calcium Carbonate Powder Coating Machine

Get Latest Price

US$ 25500

≥1 Sets

US$ 5000

≥5 Sets

Quick Details

Machine Type:

Industrial machine, Painting Equipment, Coating Equipment, Other

Place of Origin:

Shanghai

Brand Name:

Clirik

Voltage:

220v

Product Details

Calcium Carbonate Stearic Acid Reaction Milling Machine Calcium Carbonate Powder Coating Machine

The powder surtace treatment is mainly completed by means of three modifying ollerses The dry powder and dosedagent are put into the mditying rllrs simultaneously. With high speed rotation. the power and agent is unning inthe form of fuidizing vortex. The modification is going on with the heat generated by high speed shearing, cllidinggand friction among the rotor, stator and the powder.

Powder Surface Coating Machine Main Specification

| Model | CLG-200 | CLG-3/300 | CLG-3/600 | CLG-3/900 |

| Main Powder(Kw) | 3*4 | 3*18.5 | 3*37 | 3*75 |

| Blower Power(Kw) | 2.2 | 5.5 | 15-22 | 45 |

| Speed of Shaft(r.p.m) | 5700 | 4500 | 2700 | 2000 |

| Capacity(kg/h) | 40-150 | 500-1800 | 2000-4000 | 4000-7000 |

| Weight(t) | 1 | 3 | 10 | 20 |

| Overall Dimension-L*W*H(mm) | 3200*600*2200 | 5800*1800*5600 | 11200*3100*6200 | 21000*3800*6500 |

Powder Surface Coating Machine Working Features

1. Continuous operation, large capacity, suitable for industrialized production in various scale.

2. High eficiencg and less consumption of modifying agent, high covering and active index of powder, energy saving

3. Both modifying and dispersion function, suitable for any fine materials, special active effect formaterial witsmall proportion and big cubage weight like white carbon, mica powder and talcum powder.

4. Powder and agent mixing and running in high speed and vortex, high modifying efficiency, with little change of granulate shape.

5. Running in negative pressure working condition, air tight, no dust leakage, no pollution, good operationcondition, low labor intensity.

6. Operating in heat and cold conditions, no additional heating or cooling system required, easy operation.

7. Independent fluid and non-fluid agent adding system for continuous, stable and evenly operation.

Powder Surface Coating Machine Application

Clirik CLG series powder surface coating machine is a new-type surface modification machine developed by our company for decades, the machine use for powders disperse,surface modification and work continuously. Especially suitable in surface modification of calcium carbonate, clay, graphite, talc, silica powders etc.

Powder Surface Coating Machine Structure

1. Hopper: materials enter into hopper from sio or bags. Humidity of feding materials should be less than 0.5%.

2. Conveying device: double screws and adjustable speed ensure the stability of mateial flow

3. Agent adding system with temperature control: Automatic temperature control system, free setting of melting temperature, suitable for various modifying agentsin both solid and liquid form.

4. Main machine: Consisting of 3 modifying rollers in triangle form, compact design, high efficiency and stablerunning.

5. Cyclone dust collector: diffusion type

6. Impuise type bag dust collector: new generation pleat filter, with the advantage of little space, large filtrationarea, high dust removal efficiency and easy cleaning.

------------------------------------------------------Clirik Related Machines ------------------------------------------------------

As a professional mining equipment manufacturer, besides the Powder Coating Machine, Clirik also can supply powder grinding mills, crushers and tec..

more information you are welcome to visit our ' Online Store '

------------------------------------------------------------------------------------------ ------------------------------------------------------

Powder Surface Coating Machine Manufatcurer

Shanghai Clirik Machinery Co. Ltd., located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Clirik Had Passed These Certification

Our Workshop

Our Team

Team Building

Exhibition We Attend

Customer Visit

Customer Site

Why Choose Us?

We keep the service idea of "creat more value to customers" , treating our customers with all our hearts, and meantime lawfully running it. Our customers distribute in over 120 countries in Asia, Europe, Middle east,Oceania and America. We apply our professional

knowledge and full global service capability to ensure the best results for our customer's business.

Pre-sale services

Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investments;

♥ Select equipment model;

♥ Sdeign and manufacture products according to clients' special requirement;

♥ Train technical personnel for clients.

Services during the sale

Respect clients; devote ourselves to improving the total value of clients.

♥ Pre-check and accept products ahead of delivery;

♥ help clients to draft solution.

After-sales service

Provide considerate services to minimize clients' worries.

♥ Assist clients to prepare for the first construction scheme;

♥ Install and debug the equipment;

♥ Train the first-line operators on site;

♥ Examine the equipment regularly;

♥ Take initiative to eliminate the troubles rapidly at site;

♥ Distribute the guarantee fittings door-to-door;

♥ Provide technical exchanging;

♥ Provide maintenance for big items

Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investments;

♥ Select equipment model;

♥ Sdeign and manufacture products according to clients' special requirement;

♥ Train technical personnel for clients.

Services during the sale

Respect clients; devote ourselves to improving the total value of clients.

♥ Pre-check and accept products ahead of delivery;

♥ help clients to draft solution.

After-sales service

Provide considerate services to minimize clients' worries.

♥ Assist clients to prepare for the first construction scheme;

♥ Install and debug the equipment;

♥ Train the first-line operators on site;

♥ Examine the equipment regularly;

♥ Take initiative to eliminate the troubles rapidly at site;

♥ Distribute the guarantee fittings door-to-door;

♥ Provide technical exchanging;

♥ Provide maintenance for big items

Packing&Shipping Service

FAQ

1. who are we?

Shanghai Clirik based in Shanghai, China, start from 2010,sell to Mid East(30.00%),Africa(20.00%),Southeast Asia(19.00%),South Asia(15.00%),North America(3.00%),South America(3.00%),Domestic Market(3.00%),Southern Europe(2.00%),Eastern Europe(00.00%),Eastern Asia(00.00%),Western Europe(00.00%),Central America(00.00%),Northern Europe(00.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Grinding Mill, Crusher and other stone powder production needed machines

4. why should you buy from us not from other suppliers?

1. CE, ISO9001

2. factory sell directly

3. 30 years experience, professional

4. Sales market all over the world

5. good after sales serive

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CPT,DDU,Express Delivery;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,French

------------------------------------------------------------------------------------------ ------------------------------------------------------

If you are interested in our Powder Coating Machine , you are welcome to levae your inquiry here, we will let our sales manager share more details for you soon.

Hot Searches