NaN / 0

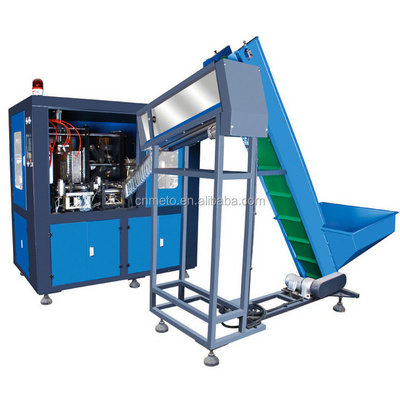

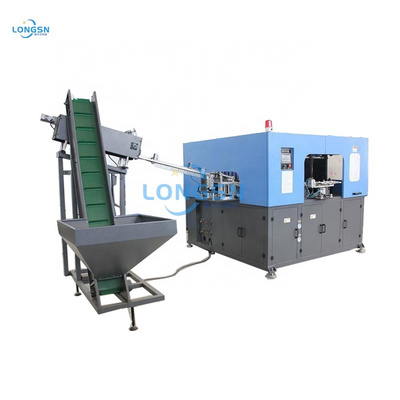

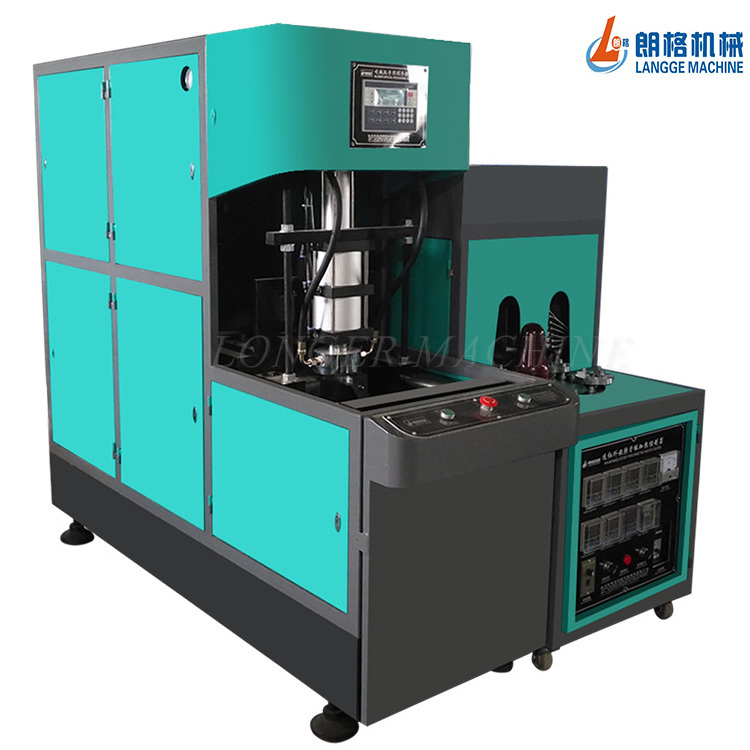

PET Jerry can Blow Molding Machine, PET blower machine,plastic bottle making machine

Get Latest Price

US$ 4900

≥1 Sets

Quick Details

Neck Diameter(mm):

140 mm

Max.Bottle Diameter(mm):

240 mm

Max.Bottle Height(mm):

450 mm

Bottle Volume(ml):

10000 ml

Product Details

Product Description

Main Features

Features

1. Produce bottle from 6L to 10L(1 cavity)

2. Output capacity up to 300 for 6L using two-cavity blow mold

3. Advanced PLC control system with a use-friendly panel and time-control precision of PLC up to 0.01second

4. Equipped with special designed air storage unit

5. Using Infrared preform heater

6. Independent Temperature Control for different heating lamp to get ideal preform heating results

7. Heating lamps are adjustable in directions to suit various preforms.

8. Operated only by one person without special training.

9. Simple installation & startup adjustment.

|

Item

|

UNIT

|

LGB-10L

|

|

Theoretical output

|

pcs/h

|

300-350

|

|

Max. container volume

|

L

|

1

|

|

Max. neck diameter

|

mm

|

140

|

|

Max. container diameter

|

mm

|

240

|

|

Max. Ccontainer height

|

mm

|

450

|

|

Mould Thickness

|

mm

|

200-300

|

|

Mould stroke

|

mm

|

255

|

|

Heat Lamp amount

|

pcs

|

40

|

|

Max. heating power

|

kw

|

32

|

|

Power of mian blower

|

kw

|

33

|

|

Actual power consumption

|

kw

|

13-18kw

|

|

Working pressure

|

Mpa

|

0.8

|

|

Low pressure consuming

|

Ltr/min

|

600

|

|

Blowing pressure

|

Mpa

|

3

|

|

High pressure consuming

|

Ltr/min

|

600

|

|

Measurement of main blower

|

mm

|

1970*610*1650

|

|

Weight of preheater

|

mm

|

2180*600*1380

|

|

Weight of main blower

|

kg

|

1000

|

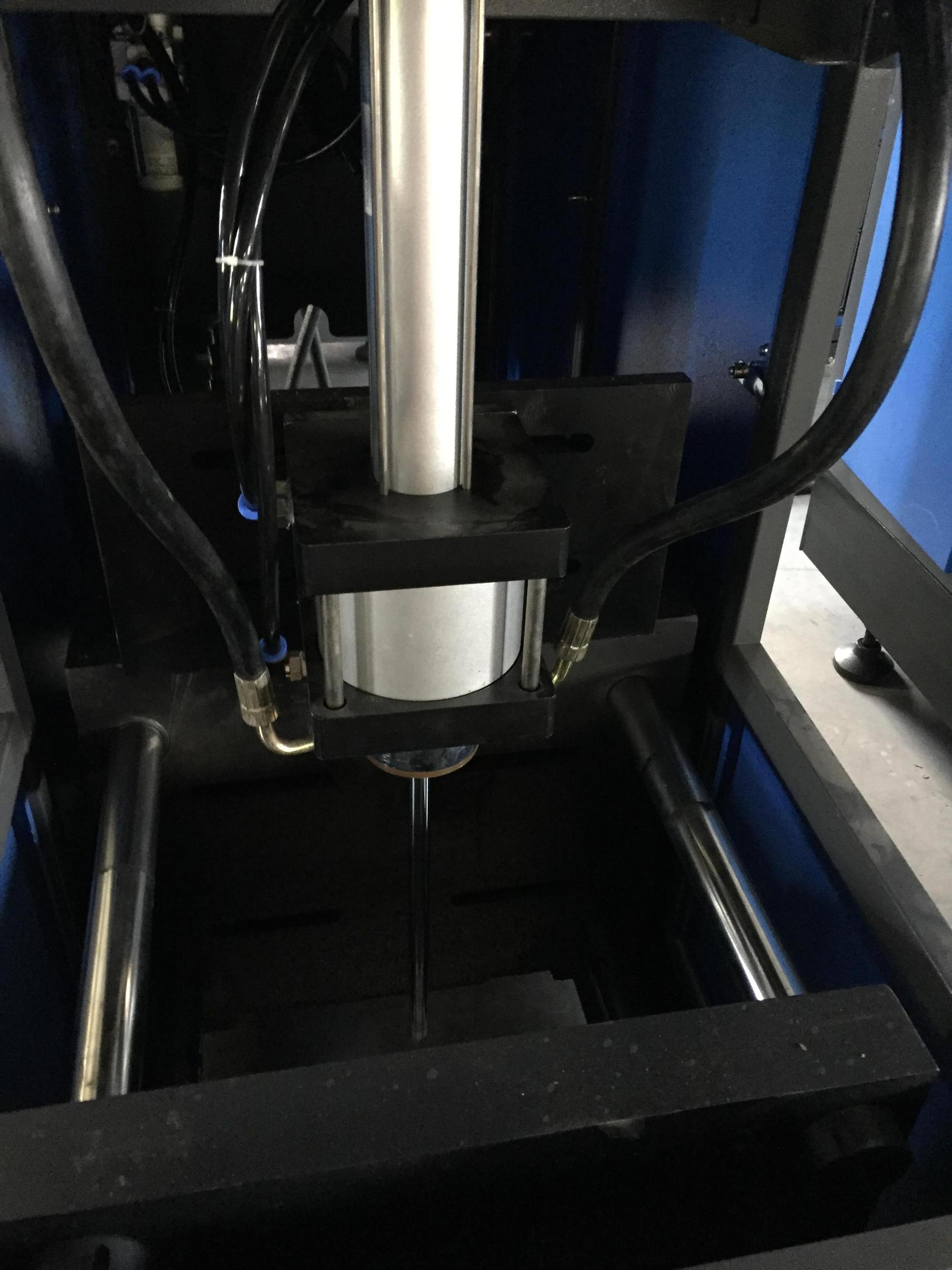

PDetailed Images

blow process

compamny information

Packing & Delivery

Contacts

Related Products

Hot Searches