NaN / 0

Firewood drying kiln wood kiln dryer machine for sale

Get Latest Price

US$ 8800

≥1 Sets

US$ 6800

≥3 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

YM

Machine Type:

wood drying equipment

Weight (KG):

800 KG

Product Details

Product information

The steam heating wood drying kiln uses circulating steam as a heat source to continuously decompose and evaporate the moisture content and lipids in the materials or products that need to be dried, so as to achieve the purpose of cleaning, drying and shaping.

Aluminum Alloy Wood Drying Kiln they have advanced and flexible controlling methods and they are easy for operation. The controlling precisions of temperature, humidity and water content rate are high. They have low power consumption. Drying quality is good and without pollution.

Specification

|

Drying Capacity

|

Pipe Position

|

Drying Oven

|

Fan

|

Drying Room

|

Axial Flow Fan

|

|

30cbm

|

roof

|

YM-30

|

4kw

|

6*4.5*4m

|

2.2kw*3(1spare)

|

|

50cbm

|

floor

|

YM-50

|

7.5kw

|

6.5*6*4.5m

|

2.2kw*4(1spare)

|

|

100cbm

|

floor

|

YM-100

|

11kw

|

8.5*7.5*5m

|

2.2kw*3(1spare)

|

Product details

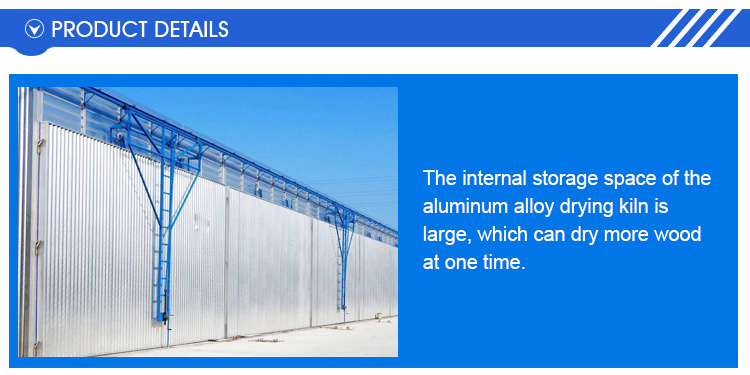

The internal storage space of the aluminum alloy drying kiln is large, which can dry more wood at one time.

Fully automatic PLC control system, easy to operate.

Product advantages

1. Heating evenly: the fan forces the air to circulate, so that the temperature difference between the upper and lower sides of the dryer is small. The unique adjustable air distribution perforated plate, hot air acts on water molecules, so the part with high water content absorbs more hot air power than water content. low part. This is the feature of selective heating, which can be used to achieve uniform heating and uniform drying.

2. Energy saving: The hot air is closed and descended in the drying box, with high thermal efficiency and energy saving. The hot air directly acts on the material, so there is no additional heat loss, and the air in the furnace and the corresponding container will not generate heat, so the thermal efficiency is extremely high, and the production environment is also significantly improved.

3. The temperature and humidity in the drying box are automatically controlled to ensure the appropriate temperature and humidity required for drying (including automatic heating, intelligent moisture removal and dehumidification system,)

4. Drying time ladder control, truly automatic management. There is an alarm.

5. Fast drying, large and fast moisture discharge.

6. Using low humidity and constant temperature drying, the products after drying are of high quality and good color.

7. The machine has reasonable structure, convenient installation and maintenance, stable operation, simple use, long service life, low operating cost, and a reasonable source can be selected according to the situation. (Can be customized for electric heating or coal burning, coal and electricity dual use, etc.)

Product application

The wood-specific drying unit can be applied to all furniture and wood balance health preservation, wood intelligent drying, wood veneer drying, wood secondary drying, etc.; it can realize low-cost operation of wood drying, one key to complete the whole process of automatic humidification and drying, the drying cycle of finished products is short, the yield of finished products is high, and the drying process is pollution-free.

There are many types of wood, commonly used wood are:

Product comparison

Hot Searches