NaN / 0

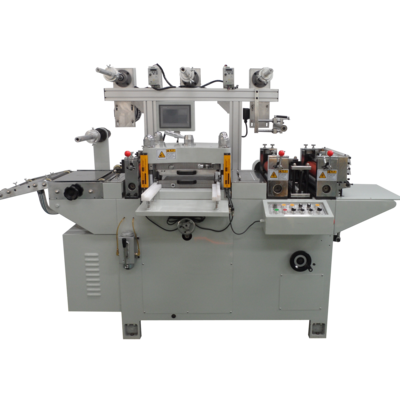

Thermal Transfer Paper Sticker Roll Kiss Cut Die Cutting Machine for Labels

Get Latest Price

US$ 5500

≥1 Sets

US$ 5200

≥2 Sets

US$ 4900

≥3 Sets

Quick Details

Type:

Die-cutting Machine

Production Capacity:

120m/min

Max. workable width:

450mm

Place of Origin:

Zhejiang, China

Product Details

The global famous label packing company we have cooperated are:

Blank label

Products Description

Application

:

This type of machine is the most ideal machine for label slitting. It has other functions such as automatic inspection, automatic correcting, automatic counter, etc, can be finished in once process.

Advantage

:

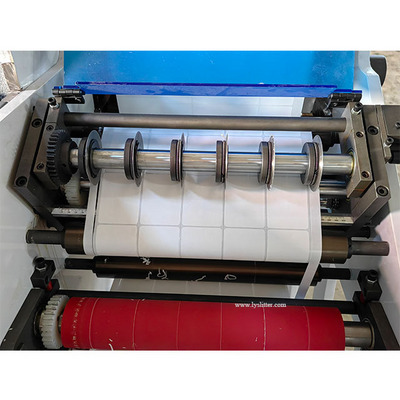

1. Synchronous belt transmission can assure the noise much smaller.

2. 1 inch, 2 inch, 3 inch tube all can be used for this type of machine.

3. Air shaft rewinding.

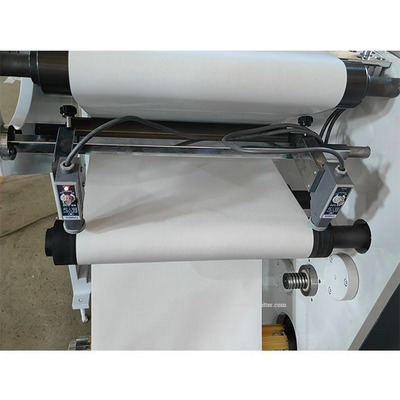

4. Taper tension controller adopted for more friendly tension control of unwinding and rewinding unit.

5. Photocell correction is used in EPC/LPC.

Technical Parameter

|

Machine model

|

HC-320B

|

HC-420B

|

|

|

Slitting speed

|

120m/min

|

|

|

|

Die-cutting speed

|

120m/min

|

|

|

|

Max unwinding width

|

320mm

|

420mm

|

|

|

Rewinding roller diameter(2 rollers)

|

φ480mm

|

|

|

|

Rewinding roller diameter (1 roller)

|

φ550mm

|

|

|

|

Machine precision

|

±0.15mm

|

|

|

|

Voltage

|

220V±10%

|

|

|

|

Main motor power

|

2.5kw

|

|

|

|

Machine weight

|

600KG

|

700KG

|

|

|

Machine overall dimension

|

1600*1100*1700mm

|

1600*1200*1700mm

|

|

Details Images

Related Products

Why Choose Us

1. Quality Control

Incoming Quality Control

Our quality team will inspect the incoming parts before storage by sampling.

Process Quality Control

Our quality team will pick the first pcs of each kind part to inspect before assembly and also inspect randomly on site.

Outgoing Quality Control

Our quality team will inspect the machine’s appearance, features and characteristic etc. before delivery to meet and exceed client’s expectation.

2. Packing & Delivery

3. Certifications

4. Our Service

Inquiry and consulting support.

Sample material testing support.

Lead the customer to visit our factory if required.

12 months guarantee, life-long time technic maintenance and support.

Online Guidance support. Spare parts supports.

24 Hours * 7 days service online.

Hot Searches