NaN / 0

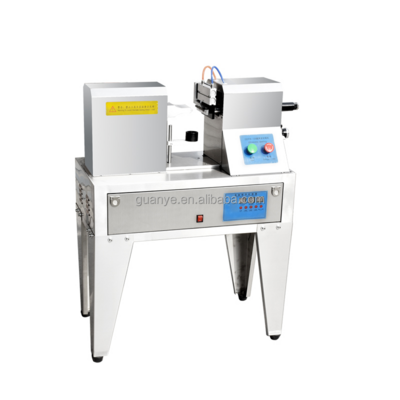

HYTS-120 Semi-automatic Soft Tube Ultrasonic Tail Sealing Machine

Get Latest Price

US$ 2900

≥1 Sets

US$ 2800

≥3 Sets

US$ 2690

≥10 Sets

Quick Details

Packaging Type:

Tubes

Packaging Material:

Plastic, Plastic composite, Aluminum plastic

Driven Type:

Electric

Max Speed:

10-12pcs/min

Product Details

HYTS-120 Semi-automatic Soft Tube

Ultrasonic Tail Sealing Machine

Product Description

Product Introduction

HYTS-120 Semi-automatic Soft Tube Ultrasonic Tail Sealing Machine

is suitable for sealing p

lastic composite and aluminum plastic

tubes,

emboss stamp

lot number.

It is used in the industries of pharmaceutics, foodstuffs, cosmetic and daily chemicals . With touch screen and the PLC control system employed, convenient, visualized and reliable non-touch operation the machine is effected compact design. Manually feeding tubes, e

xpanding tube opening,

marking identification,

ultrasonic

sealing, code embossing, trimming by automatic system, manually take products.

The high frequency u

ltrasonic

acts on the two surfaces of the tubes and the heat generated by the vibration causes these two surfaces to be welded together tightly, the strength of welding area is the same as other area of the plastic. No need adhesive or heating. Replace the traditional hot pressing or bonding process, Low cost, no pollution and no damage to tubes.

The materials is made of stainless steel, clean, sanitary and conforming to GMP.

Machine Application

Tube material: plastic soft tube, aluminum plastic or plastic laminate tube

For examples: ointment soft tube tail sealing machine, adhesives tube sealing machine, AB glue plastic tube

ultrasonic sealing machine

, Neoprene soft tube sealer, epoxy glue aluminum plastic tube tail sealing machine, skin cream soft tube sealer, hair cream tube sealing machine, boots oil tube tail sealer, toothpaste tube semi-automatic sealing machine, hand cream soft tube sealing equipment, etc.

HYTS-120 Semi-automatic Soft Tube Ultrasonic Tail Sealing Machine

|

Technical Parameters

|

|

|

|

Production capacity

|

8-12pcs/min

|

|

|

Tube dia.

|

12-50mm

|

|

|

Tube height

|

50-220mm

|

|

|

Safety protection

|

overload protection

|

|

|

Rejection rate

|

< 1%

|

|

|

Function

|

Tube tail sealing

|

|

|

Automation

|

Semi-automatic

|

|

|

Power

|

2Kw

|

|

|

Ultrasonic frequency

|

20kHz

|

|

|

Station qty

|

One

|

|

|

Suitable tube

|

Single layer tube or Double layers tube

|

|

|

Tube material

|

Plastic composite pipe, aluminum plastic pipe

|

|

|

Automatic identification system

|

No pipe, no tail sealing

|

|

|

Compressed air

|

0.6MPa

|

|

|

Dimension

|

86(L) x 64(W) x 66(H) cm

|

|

|

Net weight

|

72kgs

|

|

|

General power supply

|

AC 220V/110V(Optional), Single phase, Globally customized

|

|

Main Features

1) This machine adopts ultrasonic wave to calculate the sealing, and the sealing effect is stable and lasting; The sealing line is clear without deformation. 2) The independently developed digital automatic ultrasonic automatic frequency tracking electric box eliminates the need for manual frequency adjustment and increases the automatic power compensation function, which will not reduce the machine power due to long service time. The power can be automatically adjusted according to the hose material and size, with stable handling, extremely low failure rate and longer service life than the ordinary electric box. 3) PLC touch screen control, easy to operate. 4) The whole machine is made of 304 stainless steel, corrosion resistance, acid and alkali resistance. 5) Japanese Panasonic‘s highly sensitive benchmarking electric eye is used to configure the stepping motor, which makes the benchmarking fast and accurate.

6)

Small floor space, high cost performance, easy to learn.

7) The product is easy to change, only one mold can be changed.

8)

Equipped with safety device, no induction, no tail sealing, overload protection.

9) Well-known brand electrical appliances are durable and not easy to break.

10) Filling machine can be chosen.

Machine Display

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Packaging

|

|

|

|

Size

|

96(L) *75(W) * 86(H) CM

|

|

|

Weight

|

120KG

|

|

|

Packaging Details

|

1.The machine is packed by PE film first. Then packed in wooden box.

2. For full container load, we will use pallet. If container is too tight, we will use pe film for packing or pack it according to customers special request.

|

|

Related Products

About US

Certificate Display

Our Costomers

Factory & Logistics

Hot Searches