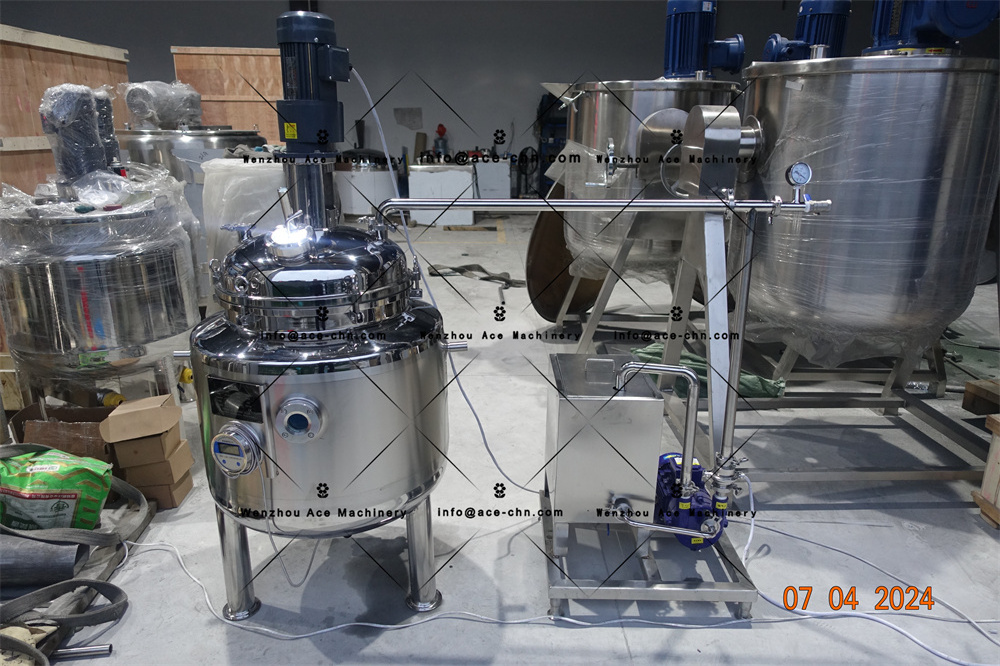

Complete process of dissolving, mixing, heating and cooling in one unit

Working capacity from 50L to 30000L

Variable speed for agitator

Double jackets for heating and cooling

Different jacket designs available for steam and electric heating

Double temperature probes and controllers for electrical heating in mixer tank

Vacuum system to take out the air bubbles during mixing and to transfer the ingredients

All contact parts are made of SS304/316L and mirror polished

Push buttons control panel for easy operation