NaN / 0

woven label making machine / adhesive labeling machine / adhesive sticker labeling machine

Get Latest Price

US$ 8500

≥1 Sets

Quick Details

Application:

Food, Beverage, Machinery & Hardware

Packaging Type:

Bottles

Packaging Material:

Plastic

Place of Origin:

Jiangsu, China

Product Details

Product Description

Double head shrink sleeve labeling machine.

1.Whole machine adopt qualified stainless steel and good-quality of aluminum alloy , compact and reasonable fracture,convenient to adjust;

2.The label roll frame of shrinkage film with adjustable device, convenient to adjust according to differ volume label 5″~10″paper tube.

3.Simply installation, then can convenient for square and round bottle.

4.No need of instrument, rotary mechanism is convenient to adjust, apply to different bottle type.

5.Unique sleeve labeling method, adopt pressing sleeve labeling method, not only convenient but also reasonable.

6.Control the feeding system automatically, and flat the shrinkage film and adjust strain simultaneity.

7.Unique design knife plate, in the determined range, can change the knife base. Knife changing quickly and conveniently.

8.Middle guide-pole clip system, mould changing quickly, no need any instrument.

9.Label location system, can promote and demote in-phase adjust location according to specific bottle type requirement.

10.Imported servo system and high-sensitivity photoelectric from Japan, with high cutting precision of label.

11.Stainless steel electric control cabinet, OMRON PLC, imported from Japan.

12.Adopt advanced man-computer Interface auto controlling technology, key electric component all adopt international famous industrial brand.

Other Products

Single head shrink sleeve labeling machine.

This machine adopts international advanced technology;cover the circle label on the PET bottle.And then hot shrinking to fix on the position which bottle body designated.

The machinery part adopts combination designing of modularization,and makes the machine reasonable.The height adjustment adopts motor fluctuating;it is convenient replace the material.The special cutter head designing,make the film-rolling cut more exactly and reliably.

Steam generator for shrink sleeve labeling machine

The water is fed into the series of wholly automatic electrical heating generator by high pressure potential vortex pump made of copper with short water-supply time and durable service. A floating ball for liquid level is fixed in the water tank to automatically control the water inlet. Working system is all automatically controlled. After connecting the water supply and power supply for 5 minutes or so, it can output the steam continuously with a high level of working efficiency.

Shrink tunnel for shrink sleeve labeling machine.

In the case of different and irregular round bottles, square bottles and flat bottles etc, the new-style steam shrinking oven is easy to adjust and maintain. It has an even shrinking. The distribution of Iow-pressure steam drum and spouting way of steam are uniform and designed with seamless tube. The nozzle is divided to be adjustable three segments and the height, position and steam output of every segment can be adjusted respectively so as to gain the perfect shrinking effect.

OPP hot melt labeling machine.

OPP Hot Melt Labeling Machine is suitable for labeling round, square and other shape of PET/PP/PP bottle for mineral water, beverage, detergent etc. The label is roll type OPP, paper or paper-plastic lamination material, which is suitable for correctly labeling under high speed. With centerilized melt glue feeding and recycling system, the damage of label and consumption of melt glue is small; the glue strip is beautiful, suitable for transparent label. The machine is PLC controled, easy operation and maintenance.

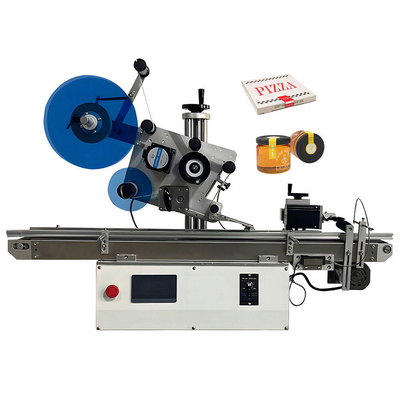

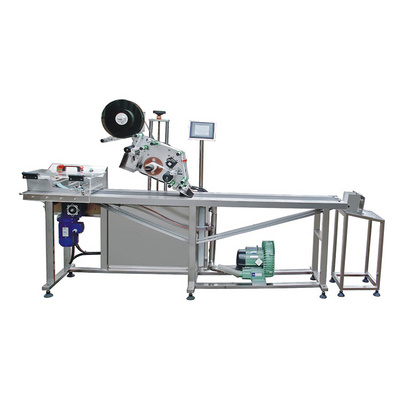

Self-adhesive labeling machine.

As the machine uses a combination of cutting-edge technologies,and high-performance components-ultra small inertia servo motor,the system by Siemens programmable logic controller professionl closed-loop control of servo motors,the use of advanced human-computer interface system implement human and computer's conversation, During the host was rushed to the label speed control process, it can reach 0.01m/min accuracy class, rather than the general machinery of 1m/min.

Different Labels for Different Labeling Machine

1/PVC/PET shrink film label.

Widely used in food, beverages, mineral water and daily products.

Material: PVC heat shrinkable film, PET heat shrinkable film.

PVC shrinkage: longitudinal shrinkage 1%-4%, transverse shrinkage 55%;

PET shrinkage: longitudinal shrinkage 1% -3%, transverse contraction 70%;

PVC/PET heat-shrinkable labels printed flattened folding diameter: not more than 270mm;

Height: according to customer requirements;

Thickness: 3 wire to 5.5 wire, according to customer requirements, roll or cut sheet can be;

Color: Up to 9 colors

2/Sticker label.

Material: Coated paper, Synthetic paper, BOPP.

Color: Up to 9 colors.

3/OPP label.

Material: PVC heat shrinkable film PET heat shrinkable film;

PVC shrinkage: longitudinal shrinkage 1%-4% lateral shrinkage 55%;

PET shrinkage: longitudinal shrinkage 1%-3% lateral shrinkage 70%

Our Company

Certifications

Our Service

Packing & Delivery

FAQ

Q1:

How to choose the most suitable machine and get the final suitable price?

A1:

For beverage bottle Filling Machine, you need to reply us the following questions:

1. What kind of product (carbonated or no carbonated beverage, juice or water) for filling?

2. What's the volume of the bottle(Can)?

3. Could you show us picture of your Bottle/can?

4. Could you send some bottle samples to us?

5. What capacity do you need for production?

Q2:

Do you have videos or manual for us to know the machine better?

A2:

Yes, of course. Please email us and ask for it. We will send you soon.

Q3:

How about your machine's quality?

A3:

Every machine is applied with CE certificate, SGS certificate, highly meets requirement of TUV, made of SUS 304 for food packaging; SUS316 for pharmaceutical products packaging. Inspect certificate is available.

Q4:

What's the delivery time?

A4:

Depending on your order: for whole production line it is 40~60 workdays. bottle or tube filling machine, labeling machine, capping machine, unscrambling machine, cansealing machine will be 30~40 days. Other simple equipment will be around 20 days. The above delivery time is calculated after receiving the down payment as well as sample bottles / tubes and materials.

Q5:

Is there MOQ for your machine?

A5:

1 set is acceptable. Of course, if you order more, it will be fine and its price will be more competitive.

Q6:

How to install the machine?

A6:

Please do not worry. We will send you detailed video and instruction manual for your reference. Customer also can appoint your engineers to our factory to learn. Our engineers also can go abroad to install the machine well, however, customer needs to pay round air tickets, hotel and service expenses.

Products&Feedback

Automatic beer filling machine

Carbonated drink filling machine

Fruit juice/tea filling machine