Openex Intelligent Technology (Shanghai) Co., Ltd

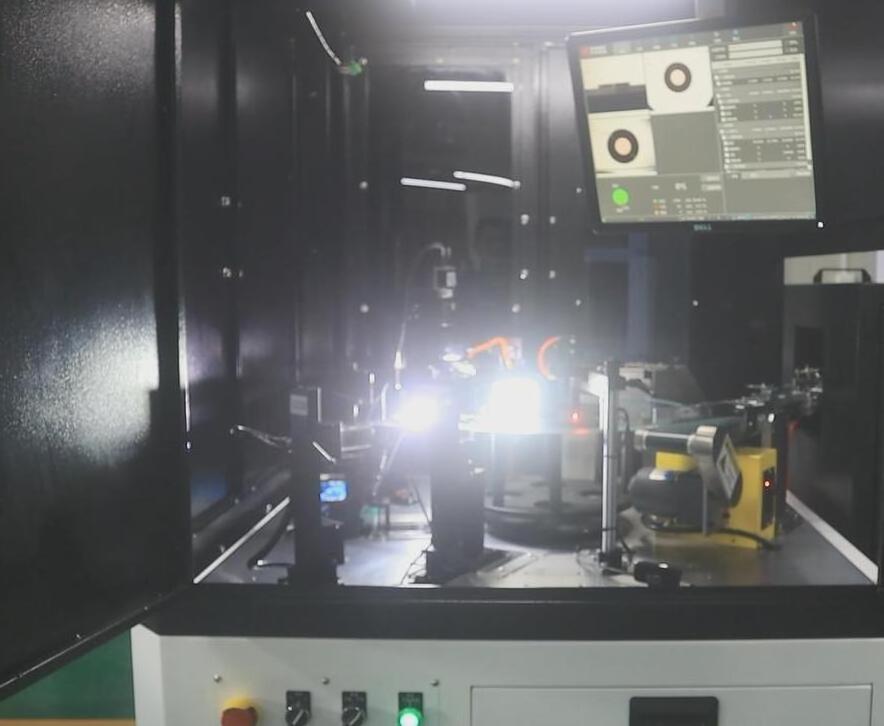

. is a high-tech enterprise under Openex Group, which develops and produces inspection machine, robots, precision optical devices and intelligent assembly lines.

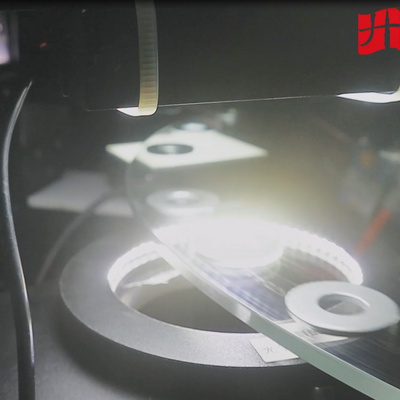

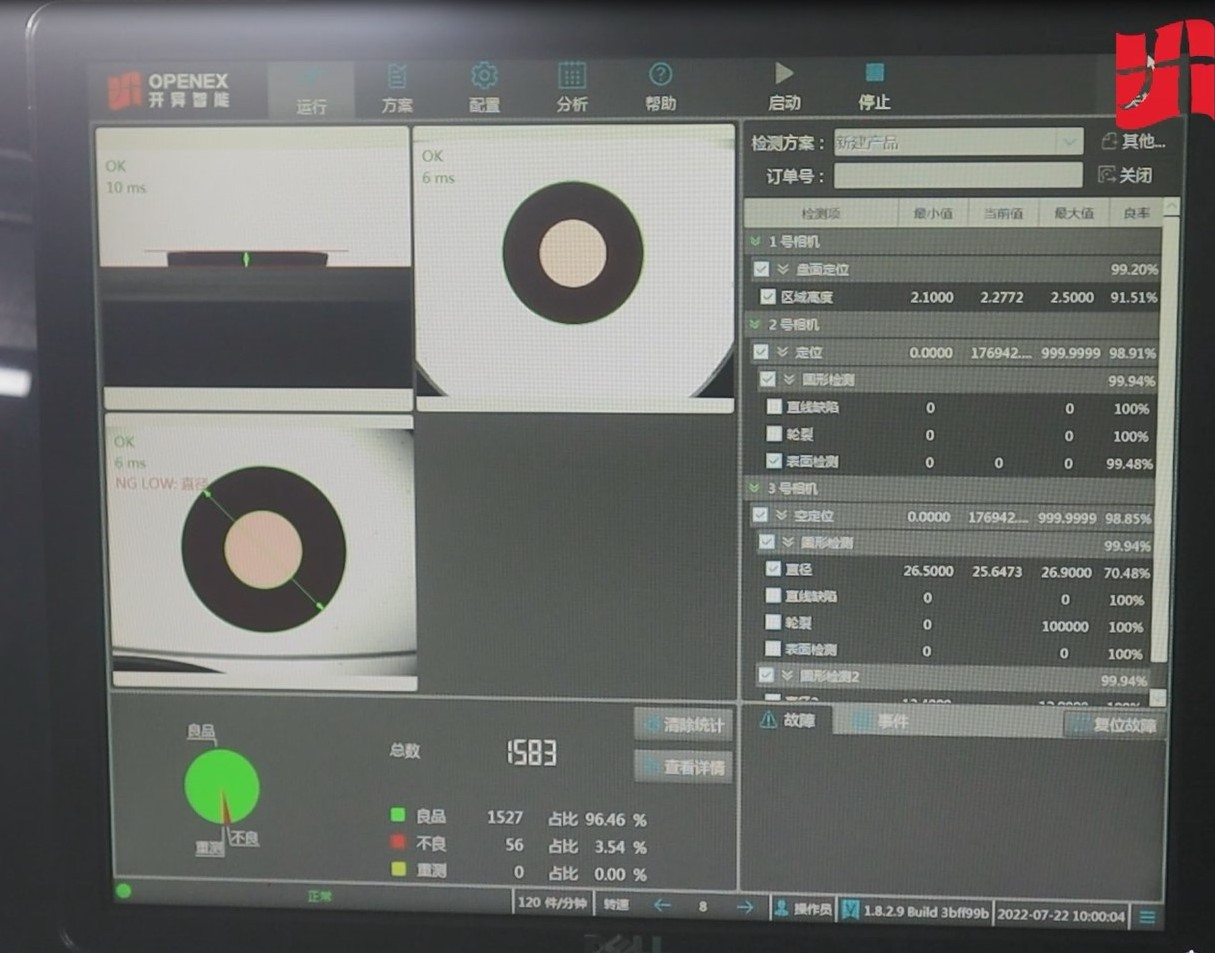

Over the years, OPENEX based on the basis of optical inspection, developed a series of part sorting machines. It includes glass disc series, slot disc series, linear series, magnetic conveyor, pinhole insertion type, electrical performance test, etc., can meet various industry needs for surface defects detection, size measurement, pattern recognition, fixed function and many other testing requirements.

OPENEX inspection machine has reached a maximum speed of 1200 parts/min, with 100% inspection accuracy, zero misjudgment and accuracy up to 0.01mm.