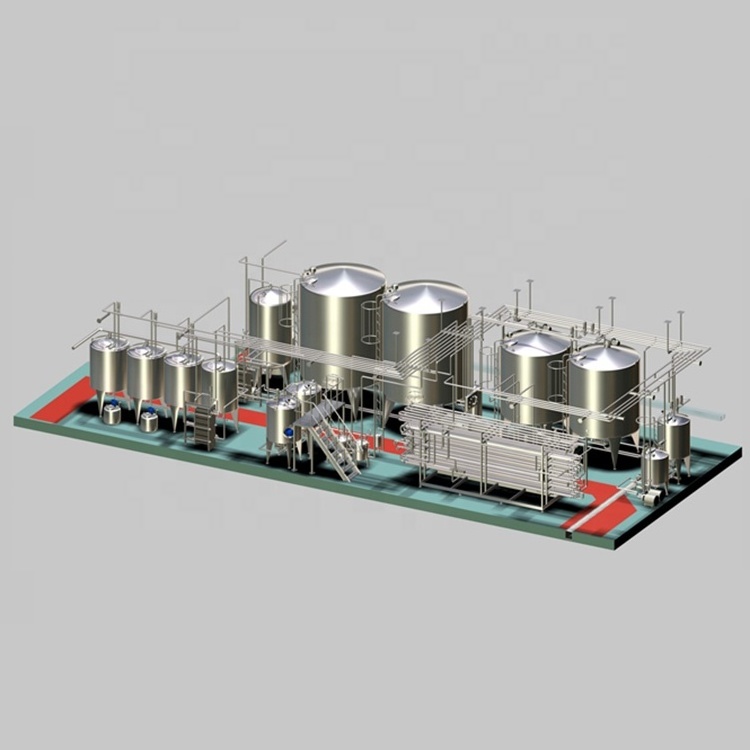

1. MILK COLLECTION SYSTEM

2. MILK STANDARD SYSTEM

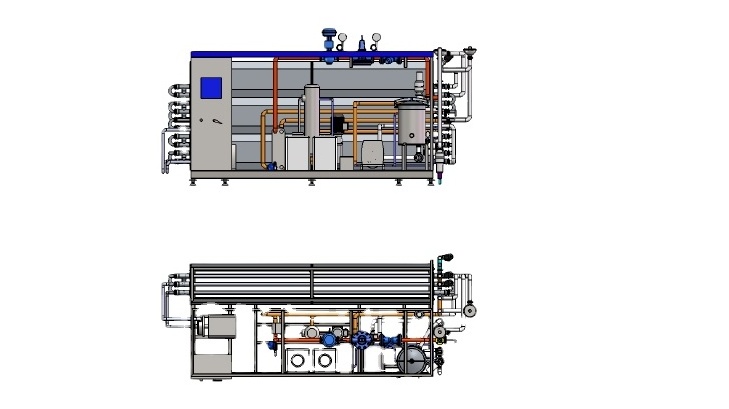

3. MILK UHT STERILIZER

4. ASEPTIC FILLER

YGT plant could flexible for UHT milk, pasteurizer, yoghurt, cream etc dairy product, capacity range from 500l/h-10,000L/h as per site need.