NaN / 0

XINYI water tank float flap flip level indicator meter sensor mechanical magnetic fuel level gauge

Get Latest Price

US$ 125

≥1 Pieces

US$ 124

≥10 Pieces

Quick Details

Grade:

Industrial

Warranty:

12 months

Place of Origin:

China

Brand Name:

xinyi

Product Details

Product Description

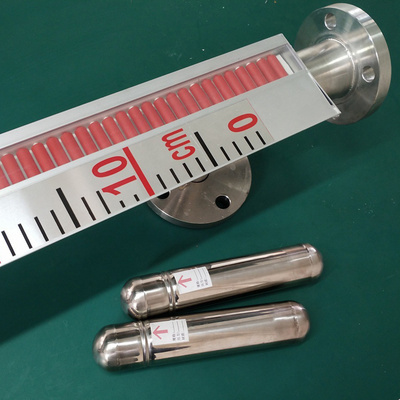

Magnetic Flap Level Gauge Side -mounted Magnetic Water Liquid Level Transducer/indicator

magnetic flap liquid level gauge is made up of measuring

body,dual-colored display cylinder, ruler, top&low flange, magnetic ball and transmitter (4-20mA). the magnetic ball in the body

of the level gauge is up or down with the liquid level changing and makes dual-colored turning to show the level of medium. Each

cylinder is with two-color axisymmetric structures. The distance of two cylinders is 10mm. Red side of display cylinder indicates

liquid and white side display cylinder indicates air. Besides measuring liquid level, it also could measure the interface of the

two kinds of liquid.

body,dual-colored display cylinder, ruler, top&low flange, magnetic ball and transmitter (4-20mA). the magnetic ball in the body

of the level gauge is up or down with the liquid level changing and makes dual-colored turning to show the level of medium. Each

cylinder is with two-color axisymmetric structures. The distance of two cylinders is 10mm. Red side of display cylinder indicates

liquid and white side display cylinder indicates air. Besides measuring liquid level, it also could measure the interface of the

two kinds of liquid.

Specification

|

(1) Center-center distance:

|

150~6000mm

|

|

|

(2) Medium density:

|

More than 0.45g/cm3

|

|

|

(3) Nominal pressure:

|

PN2.5~PN40, PN40~PN320(x 0.1MPa)

|

|

|

(4) Material:

|

SS304, 316L, PP, PTFE, or customized

|

|

|

(5)Operating temperature:

|

-190 ~ +425 °C

|

|

|

(6) Process connection:

|

DN20~DN80/RF/14,DN80~DN250/RF/14

|

|

|

(7)Indicator types:

|

|

|

|

A: Al &ABS flap cylinder

|

B: Al flap plate

|

|

|

C: PVC ABS flap cylinder

|

D: PP&ABS flap cylinder

|

|

|

E: AL &LED

|

F: PP&LED

|

|

|

(8) Structure of top chamber: |

1.Welding cover

2.welding cover with M14*1.5 plug screw 3.flange 4.flange with M14*1.5 plug screw 5.welding cover with DN20 flange 6.flange with DN20 flange 7.welding cover with air valve 8.flange with air valve |

|

|

(9) Structure of bottom chamber: |

1.flange cover

2.flange with drain plug screw 3.flange with DN20 welding tube 4.with DN20 flange 5.with needle/ball valve |

|

|

(10)Protection class:

|

IP65

|

|

|

(11)Application: Widely used in petroleum, chemical industry, oil field, pharmaceuticals industry,

food, wine industry etc., suitable for level measurements under the environment of high/low temp., high pressure, strong corrosion, toxicity. |

|

|

|

Note: Basic type, top mounted type, heat tracing type, LPG specialized type, anti-corrosive

type, boiler steam specialized type etc, they have some differences in technical parameter. Different pressure has different flange specification. |

|

|

Hot Searches