NaN / 0

Automatic Electric Stainless Steel Green Bean Slicer Cutter

Get Latest Price

US$ 5000

≥1 Sets

US$ 4500

≥2 Sets

Quick Details

Marketing Type:

New Product 2023

Place of Origin:

Zhejiang, China

Brand Name:

Wuye machinery

Type:

green beans cutter

Product Details

Product Overview

Automatic Electric Stainless Steel Green Bean Slicer Cutter

It is used for cutting head and tail of green beans, with high work efficiency, the cutting rate can reach more than 85%, and the output is 250-350 kg.

Application

Product description

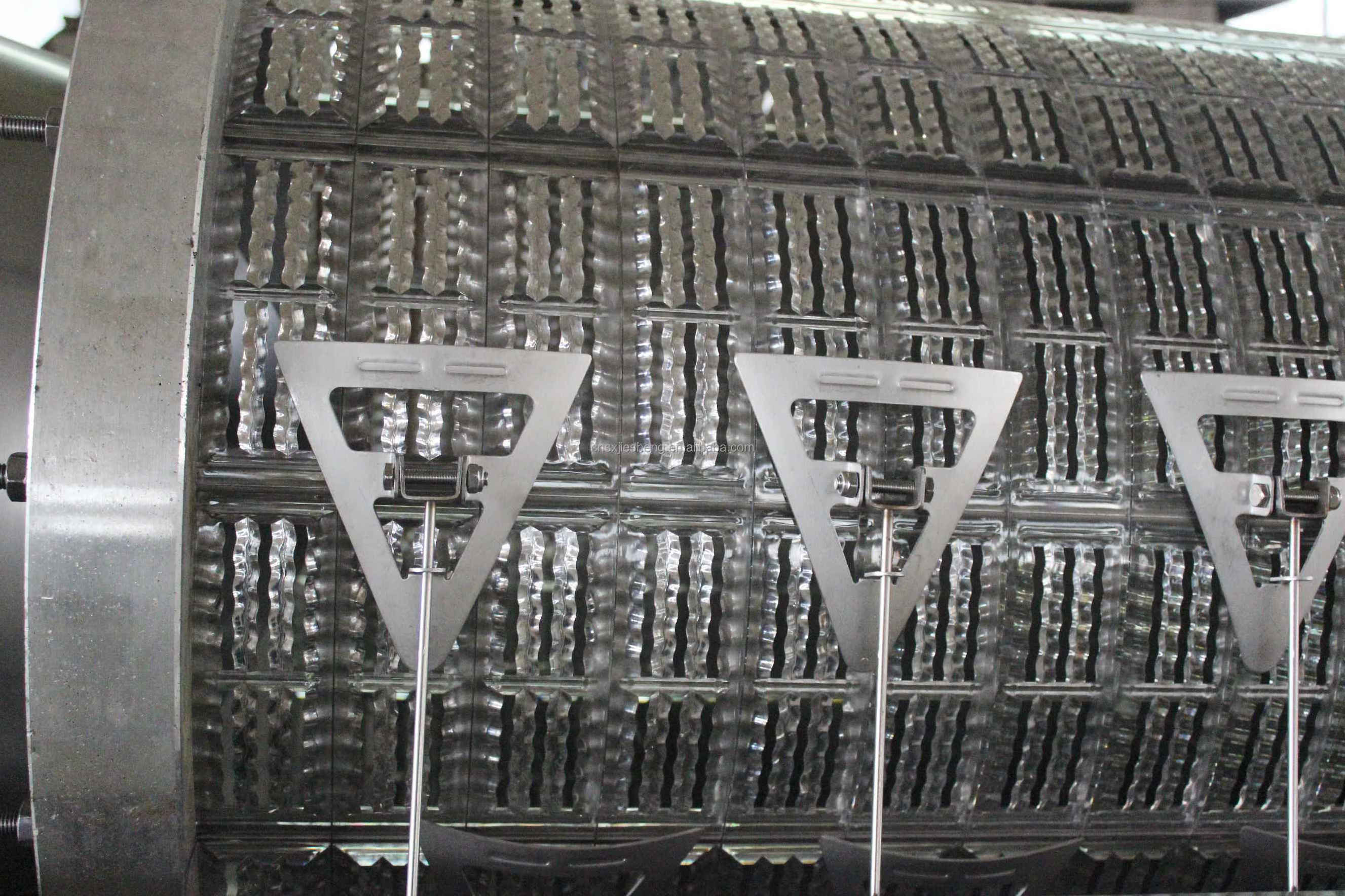

This table is composed of high-quality triangular steel knives imported from Taiwan, plastic arc knives and other important

components.

The cylinder composed of plastic arc-shaped knives is evenly rolled under the transmission of the reducer, and the steel

triangular knife is fixed closely to the arc-shaped surface of the plastic cylinder. Useless heads and tails are removed to

achieve the effect of complete removal.

components.

The cylinder composed of plastic arc-shaped knives is evenly rolled under the transmission of the reducer, and the steel

triangular knife is fixed closely to the arc-shaped surface of the plastic cylinder. Useless heads and tails are removed to

achieve the effect of complete removal.

|

Product name

|

Green beans cutter machine

|

|

|

|

|||

|

Main Material

|

High quality food grade SUS304 stainless steel

|

|

|

|

|||

|

product brand

|

Wuye

|

|

|

|

|||

|

Product origin

|

Shaoxing, Zhejiang

|

|

|

|

|||

Features

1. The equipment is made of SUS304 high-quality stainless steel, triangular steel knives imported from Taiwan, plastic arc knives, sharp and wear-resistant, high efficiency in removing heads and tails, long service life, and conforms to food hygiene standards.

2. Instead of manual pinching, the speed is fast, the labor cost can be saved by more than 100,000 yuan a year, the hourly production capacity is high, the manufacturing process is standardized, the operation is stable, and the user's high frequency utilization rate is ensured.

3. Spiral forward feeding method, and then can be connected to processing equipment such as cleaning, blanching, quick freezing, etc. It is an indispensable auxiliary equipment for the pre-treatment process of drying, dehydration, quick freezing and fresh-keeping. It is independent of the production line and can be processed and produced separately.

4. Focus on food machinery manufacturing for 26 years, professional technical and after-sales team to ensure continuous and uninterrupted processing and production. The product has a good effect of removing the head and tail, and the appearance is good, and has won unanimous praise from new and old customers.

Hot Searches