NaN / 0

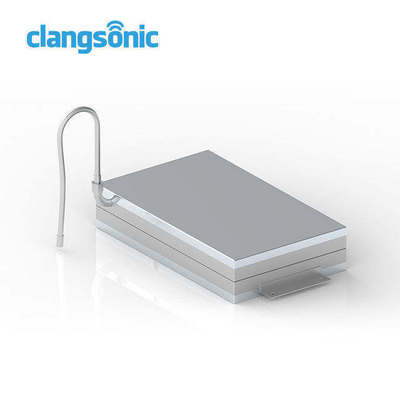

Submersible Ultrasonic Transducer Generator With Flexible Cable ultrasonic Transducer Immersible

Get Latest Price

US$ 600

≥1 Pieces

Quick Details

Place of Origin:

China

Brand Name:

AG Sonic

Power:

1800

Size:

customized Transducer Box

Product Details

Product Description

Submersible Ultrasonic Transducer Generator With Flexible Cable ultrasonic Transducer Immersible

Submersible Ultrasonic Transducer

Engineered for optimum results, Piezo-ceramic transducer elements produce a powerful ultrasonic effect for

most difficult of cleaning tasks.

Durable construction

Manufactured from high quality stainless steel, both internally and externally, the tanks are easy to maintain and keep clean.

Safe and user friendly

Tooling is simply placed into a basket and lowered in to the heated detergent,

setting of time and temperature and the operation of other features is made easy by simple front panel controls. Dry run heating protection and automatic switch off bring additional safety features

H ow are ultrasonic waves produced?

When high frequency sound waves are passed through a cleaning fluid such as water with a suitable detergent additive, many millions of microscopic bubbles form and collapse. These bubbles are the result of the stretch and compress phrases of the sound waves within the fluid, the whole process is known as cavitation. Micro-bubbles will implode under the mechanical action of ultrasonic waves and a large amount of energy will be released and the local temperature will increase. The bubbles are forced into crevices where the fluid can penetrate between the contamination and the workpiece and leaving it totally clean and free of hidden soils.

The different Ultrasonic Submersible Transducer frequencies

25 KHz - The most powerful frequency to remove strong pollution. Do NOT use on mirror polish surfaces and sensitive materials like glass, aluminum...

40 KHz - Standard frequency which can be compatible on a wide range of material and for removing a lot of pollution.

80 kHz - This frequency is used to clean parts with complex geometry. Cavitation bubbles can go into small holes to remove the pollution.

120 kHz and Megasonic - Main application in precision optics to clean very sensitive parts like wafers. The power of cavitation is low so these frequencies are used on clean parts to remove dust in final cleaning.

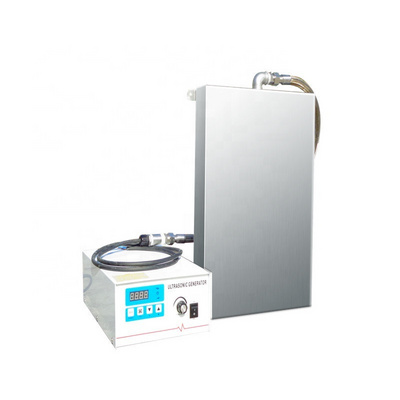

A generator, a transducer and a tank make up our ultrasonic cleaning system .

The generator supplies electrical power to the transducer, which converts to mechanical energy in the form of pressure waves.

Ultrasonic energy enters the cleaning solution in the tank, generating the cavitation that precision-cleans its contents.

IMMERSIBLE TRANSDUCERS

Simultaneous Multi- Frequency Immersibles are constructed of cavitation resistant, bright annealed, 316L stainless steel with robotically welded seams to ensure a long life. The Ceramically Enhanced Bar design consists of two transducer stacks which permit simultaneous multiple frequencies. They are available in the form of transducerized tanks and separate immersibles which are fully sealed so they can be inserted into an existing tank to convert it into an ultrasonic cleaning system. Immersible transducers are a perfect way to introduce ultrasonic energy into existing tanks. Also, the units are easily replaceable for economical repairs.

Submersible Ultrasonic Cleaner Transducer Box

Ultrasonic tanks are generally rectangular and can be manufactured in just about any size. Transducers are usually placed in the bottom or on the sides, or sometimes both when watt density (watts/gal) is a concern. The transducers can be welded directly into the tank, or watertight immersible units can be placed directly into the aqueous solution. In some instances, the immersibles may be mounted at the top of the tank facing down. For applications such as strip cleaning, one immersible is placed on the top and one on the bottom with minimal distance between them. The strip is then run through the very hard energy field. A tank should be sturdy in construction, ranging from 11-14 gauge in thickness. Larger, heavy-duty industrial tanks should be 11-12 gauge and should contain the proper stiffeners for support due to the weight of the solution.

Our immersible transducer is custom designed for your particular application and tank size. It can be incorporated into existing tanks of any size and converted it into ultrasonic tank. It is controlled by our unique Pulse Swept Pleasecontact us for specific information on how we can create one for your Immersible Transducer needs.

The range of immersible transducers come in various sizes ultrasonic powers and operating frequencies. We can select the size you need based upon your cleaning requirements and tank size. The immersible ultrasonic transducer systems are portable and can be moved from one tank to another if required. They are most suited to when you have already a tank installed in your production process or we can supply the complete system including the tank.

Immersible ultrasonic transducers are designed for use in new or existing cleaning tanks to improve the speed and effectiveness of rinsing cleaning and other processes. Single or multi- module units can be custom designed for tanks of any size.

Submersible Ultrasonic Transducer Specifications:

|

Model |

Material |

Transducers |

Estimated volume |

Box size |

Cable

|

Ultrasonic frequency |

Ultrasonic power |

|

(mm) |

(pcs) |

(L) |

(mm) |

|

(kHz) |

(W) |

|

|

TZ-1003 |

SUS304/SUS316L |

3 |

15 |

250x150x100 |

Rigid tube/

|

28/40 |

150 |

|

TZ-1006 |

6 |

30 |

305x250x100 |

300 |

|||

|

TZ-1012 |

12 |

60 |

355x250x100 |

600 |

|||

|

TZ-1018 |

18 |

90 |

406x305x100 |

900 |

|||

|

TZ-1024 |

24 |

120 |

500x355x100 |

1200 |

|||

|

TZ-1030 |

30 |

150 |

550x406x100 |

1500 |

|||

|

TZ-1036 |

36 |

180 |

500x460x100 |

1800 |

Packaging & Shipping

Our Services

Supply high quality product

Provide OEM&ODM service

One Year Warranty

24/7 response.

Technical support for all time.

Professional suggestion for your cleaning job.

Full inspection for every product we made.

Hot Searches