NaN / 0

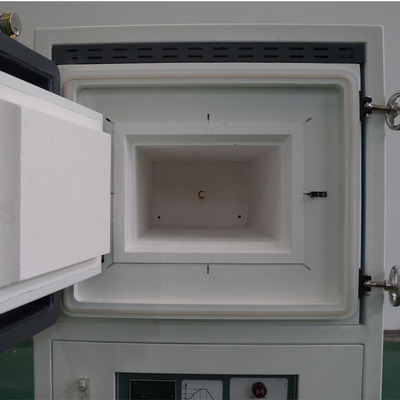

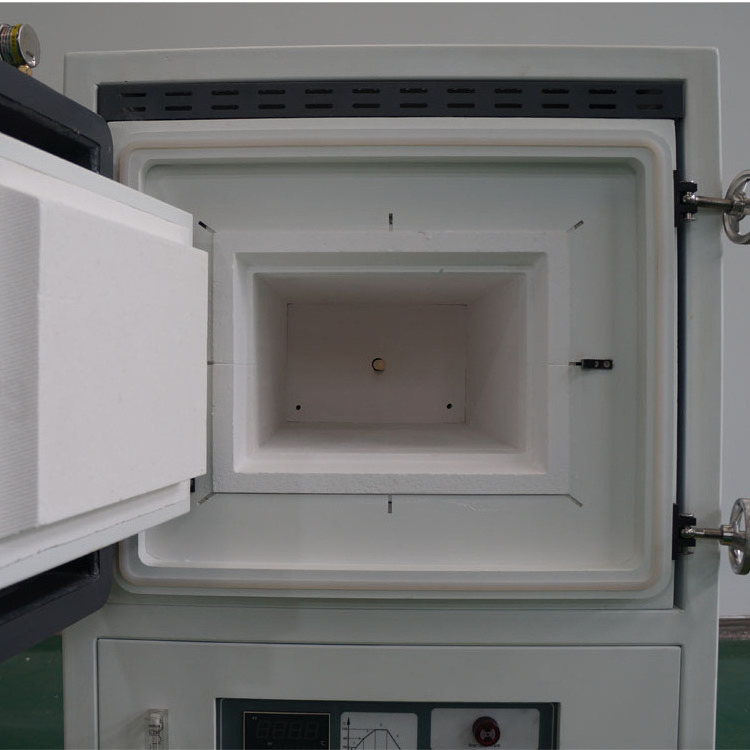

Atmosphere sintering furnace crucible furnace gemstone heating equipment

Get Latest Price

US$ 1500

≥1 Sets

Quick Details

Brand Name:

SAFtherm

Model Number:

STQ-30-12 original

Place of Origin:

China

Product name:

30 Liter Sealing Chamber heating resistance atmosphere furnace

Product Details

Product Description

Product Overview:

An atmosphere furnace provides the ideal environment for various procedures in many laboratories, providing the controlled temperature and atmosphere specific projects require. The controlled atmosphere is desired to complete tasks that require exact temperatures pricisely. This is the best way to ensure the successful test result of your project because it is sealed tightly to ensure the right environment.

STQ 1200 series controlled atmosphere furnaces feature a chamber with Mitsubishi (Japan) high quality alumina fiber insulation and the top quality heating elements. A double walled steel internal housing helps minimize heat loss to exterior surface, also keep the surface safe to touch. Furnace operation is controlled by Shimaden (Japan) 32-segment digital controller with temperature accuracy of +/- 1 C degree. Proper temperature control is vital to the success of your project as well. Temperatures that are too high or too low will cause problems with the process and could cost your company a significant amount of money. SAFTherm furnaces come with built-in 32-segment PID digital temperature controller for accurate monitoring and consistency.

Mean Features

1. Multiple gas inlets and outlets with stainless steel ball valves. Flow meter to control inbound and outbound gas flows.

2. Furnace chamber is welded and oil leak tested to ensure air tightness. Furnace door is sealed with high temperature silicon gasket.

3. Dual wall housing makesure the body cool during heavy use.

4. Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

5. Built-in ammeter and voltmeter for easy monitoring and troubleshooting.

6. Built-in computer interface.

7. Long life type N thermocouple.

8. CE certified

Technical Parameters

| Model | STQ-3-12 | STQ-8-12 | STQ-18-12 | STQ-30-12 |

| Chamber Size mm(W*D*H) | 150x150x150 | 200x300x120 | 250x300x250 | 300x500x200 |

| Power supply | 220V/2.5KW | 220V/3KW | 220V/5KW | 380V/7.5KW |

| Type |

Benchtop

Front-loading |

|||

| Usage | Atmosphere furnace is designed for material synthesis under controlled inert gas atmosphere or mixture gases with better temperature uniformity. It is an ideal heating equipment for preparing new material which requires inert gas or oxidizing gas including hydrogen gas. | |||

| Furnace structure |

1. The furnace is consist of heating system, gas system, vacuum system 2. chamber is consist of insulation material and heating elements and atmosphere boxes 3. Temperature controller is consist of PID temp. controller, control elements and thermocouple 4. Integrated the furnace body and the temperature controller in one, the furnace is fixed on the temperature controller |

|||

| Max. temperature | 1200℃ (in air) | |||

| Continuous Working temperature | 1100℃ (N2) | |||

| Heating Rate | ≤15℃/min (suggest 10℃/min for longer life using of furnace) | |||

| Heating Element |

Top brand iron-aluminum alloy resistance coil wire (HRE)

The wire elements are coiled and embedded in three sides of the wall (Elements located in ceiling, left and right sides) |

|||

| Chamber material |

1. Adopt high quality alumina polycrystalline fiber, which used Japanese technology (vac-sorb forming alumina polycrystalline fiber) with good insulation and durability properties

2. High quality 1300 degree fiber alumina as refractory lining, pure white color 3. Ceramic fiber insulation for fast heat-up and reduced energy consumption—rise time to 1100°>C takes only 50 minutes 4. Embedded heating elements on the round chamber which give an ideal temperature uniformity |

|||

| Temp. Uniformity | ±5°C | |||

| Thermocouple | N type | |||

| Temperature Controller |

1. Control system integrated in the furnace base, Defined application within the constraints of the operating instructions

2. Furnace temperature controller utilizes Intelligent PID 4 group 8 segments program 3. Feature single setpoint digital control, LED display of actual temperature VS set point 4. A high-precision digital microprocessor controller fitted with self-tuning and manual PID settings makes temperature and other parameters easy to control 5. Temperature controller Precision ±1℃ |

|||

| Atmosphere perfermance |

high temperature PTFE gasket is installed on the furnace door to ensure the reliable sealing of the furnace; Ultimate vacuum level for STQ furnaces is around 20000Pa with hose barb connections. Please keep in mind that our STQ series of atmosphere furnaces are NOT designed to be vacuum furnaces, the vacuuming part is mainly for users to pre-vacuum the chamber, before putting in inert or other protective gases. |

|||

| inlet port and outlet |

1.The inlet and outlet ports are designed on the side and back wall of the furnace body and can be supplied with inert protective gas. The gas flow rate is controlled by a float flowmeter with a range of 1-10L/min. |

|||

| Electronic component | SCHNEIDER maker air switch, buttons, solid-state relay, A.C contactor etc. | |||

| Furnace Shell |

1. High quality cold-rolled steel sheets CNC processing

2. Environmental electrostatic plastic-spraying on surface after deoiling, derusting, phosphating etc. nine processes 3. Energy efficient insulation keeps exterior safe to touch |

|||

| Safety Precautions |

1. Overheating & Broken thermocouple protection

2. Leakage circuit breaker 3. Automatic power off when furnace door opens (optional function) 4. Over-temperature protection and alarm allow for operation without attendant(s) 5. Microprocessor-based PID control with self-tuning capability to prevent overshooting of set temperature |

|||

| Supply Scope |

1. One set of atmosphere furnace body 2. Three-meter power line 1. One piece of N - type thermocouple (installed before delivery) 2. One pair of crucible tongs 3. One set of floatmeter for inert gas flowing (installed before delivery) 4. One set of water cooling device ( water inlet/outlet with valve) 5. One pair of high temperature furnace gloves 6. An instruction book |

|||

| Optional Accessories |

1. Quartz Boat

2. paperless recorder

|

|||

| Certification | ISO9001 CE | |||

| Warranty |

One year limited manufacturer's warranty (Consumable parts such as processing tubes, O-rings and heating elements are not covered by the warranty, please order replacements at related products respectively |

|||

Detail Pictures

Standard package

| Item Description | Qutity | Image |

| atmosphere furnace | 1 set | |

| Type N thermocouple | 1 pc | |

| Stainless steel tongs | 1 pair |

|

| Gas flow meter | 1 set | |

| 3-meter power line | 1 set | |

| Thermal gloves | 1 pair | |

| Furnace operation manual & temperature controller manual | 1 pc |

Packaging & Shipping

Standard Export Safe Packing:

1.The 1200c Atmosphere laboratory sintering muffle furnace price was warped with enrivonmental plastic stretch film, then fixed well on the fumigation-free pallet

2.Tailored polywood case, coupled perfectly with the pallet

3.Filled with polyfoam, fit well between the furnace body and the case in all sides

4.Easy-to-identify double-sided outer box print logos and shippment marks

Delivery Time: 30 working days against receiving advanced payment

Port: Shanghai/Qingdao

Hot Searches