NaN / 0

Plastic Single Wall Corrugated Pipe Extrusion Line Flexible Hose Making Machine

Get Latest Price

US$ 18000

≥1 Sets

US$ 17000

≥2 Sets

Quick Details

Screw Design:

Single-screw

Screw L/D Ratio:

30:1

Screw Speed (rpm):

2000 rpm

Place of Origin:

Shandong, China

Product Details

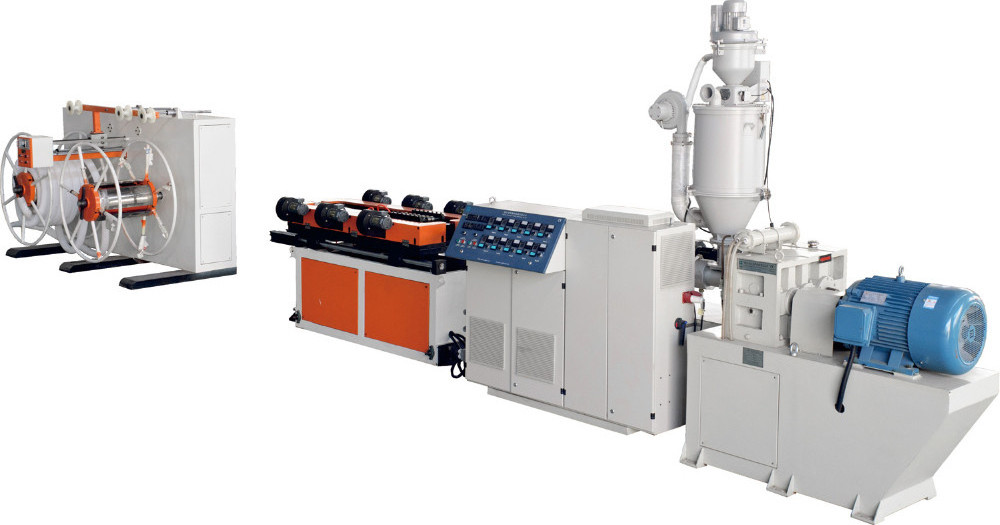

Plastic Single Wall Corrugated Pipe Extrusion Line Flexible Hose Making Machine

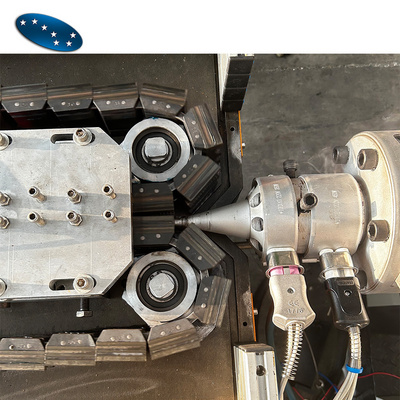

Single wall plastic corrugated pipe production line consists of extruder, mold blocks, corrugated forming machine and auto winding system.

| Pipe diameter | 4-12mm | 10-32mm | 10-32mm | 25-65mm | 50-110mm |

| Extruder | SJ-30/28 | SJ-45/30 | SJ-50/30 | SJ-65/30 | SJ-90/30 |

| Capacity | 8-15kg/h | 40kg/h | 50kg/h | 120kg/h | 250kg/h |

| Speed of production line | 1-12m/min | 1-10m/min | 10-20m/min | 1-8m/min | 1-5m/min |

| Quantity of mould block | 38 pairs | 38 pairs | 80 pairs | 38 pairs | 50 pairs |

Process Flow:

PP/PE/PVC/PA/PB/EVA material→Automatic loader →Single screw extruder→Head die and mould →Mould blocks→Forming machine→Winder

Advantages:

1. Different e xtruder size according to different size of hose.

2. Motor from famous brand.

3. Frequency convertor ABB brand.

4. High precision processing for each parts, never roughly manufacturing.

It can continuously produce many kinds of diameter single wall corrugated pipe in high speed.

Double wall corrugated Plastic granulating machine

PET bottles recycling PP/PE film recycling

and washing line and washing line

High quality obtain high praises!

Our service:

| Per-sales service |

1) sales person, project manager, accountant staff

2) professional responsible teem: would be very fastly and exactly to send you offers |

| Online/sale service |

1) super and solid quality

|

| After-sale service |

1) repairing and maintenance if any problem occur in the warranty

|

| Other cooperation service |

1) technology knowledge share

|

Hot Searches