NaN / 0

Suppliers Custom Size Undermount Workstation Kitchen Sink Single Bowl Stainless Steel With Accessories

Get Latest Price

US$ 8.05

≥500 Pieces

Quick Details

Model NO:

LM-KS-039

Transport Package:

Carton

Trademark:

Customized logo

Origin:

China

Product Details

Product Display

Stainless Steel Kitchen Sink: The Perfect Way to Upgrade Your Kitchen

Transform your daily kitchen experience with the Stainless Steel Kitchen Sink. This high-quality, durable sink is made of 304 stainless steel and features a spacious single bowl design, a built-in strainer, and a sound-absorbing undercoating. The sink is also easy to clean and maintain, making it the perfect choice for busy households.

Features:

- 304 stainless steel construction: The sink is made of high-quality, durable 304 stainless steel for long-lasting performance.

- Spacious single bowl design: The single bowl design provides ample space for washing dishes, pots, and pans.

- Built-in strainer: The built-in strainer helps to catch food particles and debris, preventing them from clogging the drain.

- Sound-absorbing undercoating: The sound-absorbing undercoating helps to reduce noise and vibration while the sink is in use.

- Easy to clean and maintain: The sink is easy to clean and maintain with a simple wipe-down.

Benefits:

- Enjoy a more efficient and productive kitchen experience.

- The spacious single bowl design makes it easy to clean large dishes and pots.

- The built-in strainer helps to keep your sink clean and free of clogs.

- The sound-absorbing undercoating helps to create a more peaceful kitchen environment.

- The sink is easy to clean and maintain, saving you time and effort.

Order your Stainless Steel Kitchen Sink today and start enjoying the benefits of a more efficient and productive kitchen!

Additional Information:

- Material: 304 Stainless Steel

- Installation Type: Undermount or Drop-in

- Bowl Dimensions:

- Single Bowl: 24" x 18" x 10"

- Overall Dimensions:

- Single Bowl: 30" x 21" x 10"

- Faucet Holes:

- Single Bowl: 1

- Drain Hole: 3.5"

We are confident that you will be happy with your purchase of the Stainless Steel Kitchen Sink. Contact us today to learn more and get a free quote.

Kitchen Sinks Application

Single kitchen sinks are an essential element in modern kitchen design, offering a range of practical applications that enhance the functionality and efficiency of the cooking space. These sinks are designed to fit into a single compartment, providing a sleek and streamlined look that complements various kitchen styles.

Firstly, single kitchen sinks are ideal for washing dishes and cookware. Their spacious design allows for easy cleaning of pots, pans, plates, and cutlery, making the task of washing up quick and efficient. Whether you're preparing a meal for a large family gathering or simply cooking for yourself, a single kitchen sink provides ample space for all your cleaning needs.

Moreover, single kitchen sinks are also suitable for performing various kitchen tasks. You can use them to rinse fruits and vegetables, fill pots with water, or even soak dirty dishes before washing them. The depth of the sink bowl ensures that you can easily immerse large items, making these tasks more convenient.

In addition to their practical uses, single kitchen sinks can also serve as a focal point in the kitchen. With their sleek design and various finish options, they can enhance the overall look of the kitchen, creating a stylish and modern appearance. Whether you choose a stainless steel sink for a contemporary kitchen or a cast iron sink for a traditional one, a single kitchen sink can complement your kitchen's design and style.

Moreover, the ease of installation of single kitchen sinks makes them a popular choice for homeowners. They can be easily integrated into the kitchen cabinetry, providing a seamless look that blends with the surrounding counters and cabinetry. This simplicity in installation also means that you can easily replace an existing sink with a new single kitchen sink, giving your kitchen a fresh and updated look.

In conclusion, single kitchen sinks offer a range of practical applications that enhance the functionality and efficiency of the kitchen. From washing dishes to performing various kitchen tasks, these sinks provide ample space and convenience. Additionally, their sleek design and easy installation make them a stylish and practical addition to any kitchen. Whether you're renovating your existing kitchen or building a new one, consider incorporating a single kitchen sink to enhance the look and functionality of your cooking space.

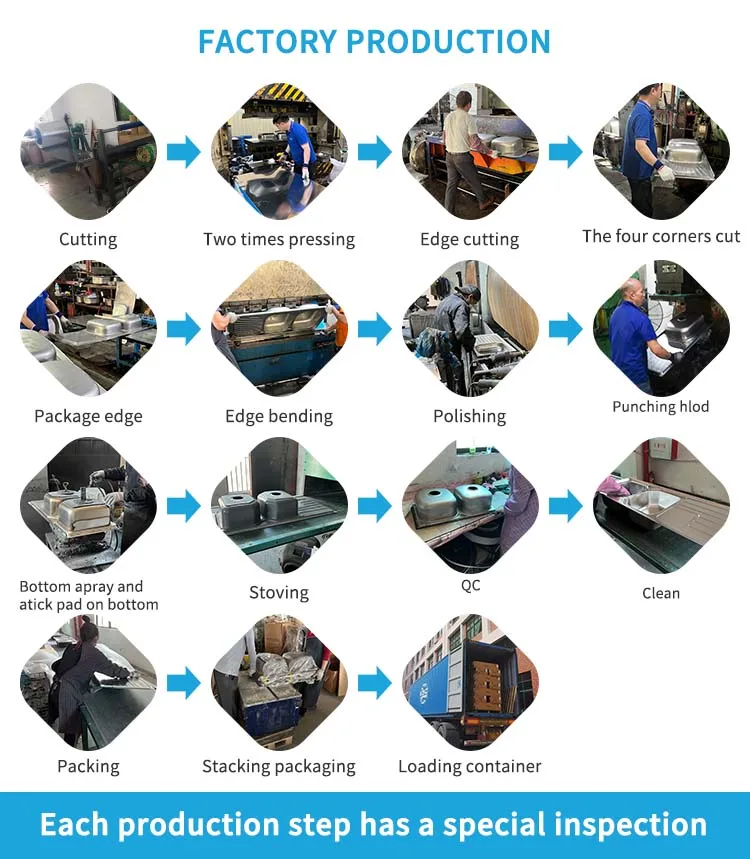

Kitchen Sinks Production Process

The production process of kitchen sinks involves multiple intricate steps that ensure the final product meets high quality standards. Here is a detailed overview of the manufacturing process:

The journey begins with the careful cutting of the materials according to the required specifications. This crucial first step, known as cutting or clipping, ensures precision in the dimensions of the components that will make up the sink.

Next, the panels are welded together to form the basic structure of the sink. This welding process ensures the panels are securely joined, creating a sturdy foundation for the sink.

Following welding, the basin or bowl is pressed into shape using specialized machinery. This pressing process forms the deep bowl that provides ample space for washing dishes and other kitchenware.

After the basin is pressed, any protective tape or adhesive strips are removed, a step known as stripping the tape. This ensures a smooth surface for the subsequent welding process.

The basin is then welded to the panel structure, creating a seamless integration of the two parts. This welding of the basin to the panel is a crucial step that ensures the sink's structural integrity.

Once the basin and panel are merged, the welded joints are carefully ground and smoothed to eliminate any rough edges. This grinding process not only enhances the sink's aesthetics but also ensures a smooth finish that is easy to clean.

The interior seams of the basin are also ground and smoothed to eliminate any sharp edges or imperfections. This step is crucial for creating a safe and comfortable workspace within the sink.

The entire surface of the sink, including the panel and basin, is then polished to a high-gloss finish. This grinding and polishing process gives the sink a sleek and professional appearance.

After the sink has been fully welded and smoothed, it undergoes a thorough quality inspection. This process ensures that each sink meets the manufacturer's strict standards for quality and durability.

Once the sink has passed the quality inspection, a soundproofing pad is applied to the underside of the sink. This pad helps reduce noise and vibration, enhancing the user experience.

The bottom of the sink is then painted with a protective coating that resists scratches and corrosion. This painting process not only enhances the sink's durability but also adds to its overall aesthetics.

The painted sink is then placed in an oven for baking or curing, a process that ensures the paint adheres securely to the sink's surface.

After baking, the sink is considered a finished product and is ready for packaging. It is carefully wrapped and protected to ensure it arrives at its destination in perfect condition.

The packaged sinks are then stored in a warehouse until they are ready to be shipped. This staging process ensures that the sinks are organized and easy to access when needed.

Finally, when it's time for shipment, the sinks are loaded into boxes and prepared for delivery to customers. This final step marks the end of the production process and the beginning of a new journey for the kitchen sink, as it finds its way into a home and becomes a functional and stylish addition to the kitchen…

Company Profile

Hangzhou Happyfull Import & Export Company Limited is a professional exporter of building materials, Construction & Decoration products.Our products include metal & stone roofing sheets, Door, Window & Accessories and ect. Additionally, we offer research and development services for new products. OEM and ODM orders are warmly welcomed.

We focus on quality control and creating value for our customers. We have passed ISO 9001 and CE certifications. Our products have been sold in many countries in Asia, the Middle East, Africa, Europe, and America, with positive feedback on their sound quality.

As one of the earliest exporters of Construction & Decoration products, we deeply understand the importance of good quality and excellent service. Our goal is to establish long-term partnerships and ensure that all clients can benefit from our cooperation.

We can not only meet the needs of end users but also serve major building materials importers with a lead time as short as 3 days.

We aim to establish long-term partnerships and ensure that all clients can benefit from our cooperation. We are looking forward to working with agents from all over the world.

Payment & Shipping

FAQ

1.What types of building materials do you supply?

Answer: We offer a wide range of building materials, including but not limited to steel, glass, tiles, roofing materials,and insulation.

2.Can I request product samples before placing a bulk order?

Answer: Yes, we encourage clients to request samples to assess the quality, specifications, and suitability of our building materials for their projects.

3.What is the minimum order quantity (MOQ) for your building materials?

Answer: The MOQ varies depending on the type of building material and specific product. Please contact our sales team for detailed information about MOQs.

4.Are your building materials compliant with international standards?

Answer: Yes, our building materials comply with relevant international standards and certifications. We can provide documentation upon request.

5.Can you customize building materials to meet specific project requirements?

Answer: Yes, we offer customization options for certain building materials. Contact our sales team to discuss your specific requirements and customization possibilities.

6.What is your lead time for production and delivery?

Answer: Production and delivery times depend on the type and quantity of building materials ordered. We provide estimated timelines upon order confirmation.