NaN / 0

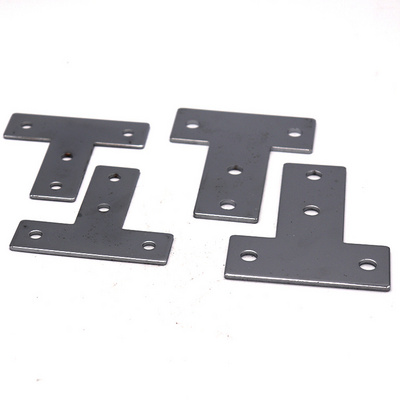

custom processing brackets sheet metal fabrication Shelf 90 Degree Angle Corner Bracket

Get Latest Price

US$ 0.03

≥1000 Pieces

Quick Details

Place of Origin:

Guangdong, China

Brand Name:

LIANXINDA

Product name:

mounting shelf metal shelf brackets for wood beams

Material:

steel

Product Details

high quality corner angle metal 304 stainless steel satin corner solar panel mounting shelf metal shelf brackets for wood beams

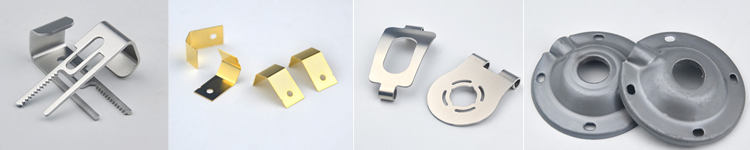

CUSTOM STAMPING PART FACTORY

We have a professional engineering team with an average industry experience of more than 6 to 8 years.

Are you ready to request a quotation for your own parts? Select an engineer that matches your project for a one-on-one discussion, quotation and solution will be provided on the same day!!

Product Description

|

Product Name

|

stamping parts

|

|

|

|

|||

|

Tolerance

|

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form.

|

|

|

|

|||

|

Processings

|

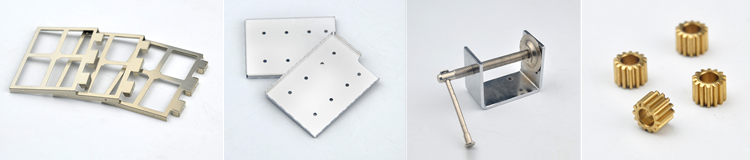

Laser Cutting, Precision Stamping, CNC Bending, CNC Milling, CNC Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting, Laser Welding, etc.

|

|

|

|

|||

|

MOQ

|

Low MOQ Start 1 Pcs ( No need mold cost ), Many Customers found us make prototype product to save Investment Funds for Pre-R&D and Market Testing.

|

|

|

|

|||

|

Sample Cost

|

Free of Sample Cost. Normally is USD 35~110 per Style Of Special Design We Need Sample Charge, Can Refund when You Have Official ulk Order.

|

|

|

|

|||

|

Delivery Time

|

1-25 days after order with prepayment based on products structure and quantity

|

|

|

|

|||

Product processing capacity ?

We are a fabrication solution partner for you

Custom made the product as your requirements is what we good at

How to Achieve your Great Ideas?

Chat with our expert now

Click Here, You'll get a response right away!

1, Main Materials

|

Stainless Steel

|

SS201,SS301,SS303, SS304, SS316, SS416 etc.

|

|

|

|

|||

|

Steel

|

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#,etc.

|

|

|

|

|||

|

Brass

|

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc.

|

|

|

|

|||

|

Copper

|

C11000,C12000,C12000, C36000 etc.

|

|

|

|

|||

|

Aluminum

|

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc.

|

|

|

|

|||

|

Iron

|

A36, 45#, 1213, 12L14, 1215 etc.

|

|

|

|

|||

|

Plastic

|

ABS, PC, PE, POM, Nylon, PP, Peek, etc.

|

|

|

|

|||

2, Surface Treatment

|

Stainless Steel

|

Polishing, Passivating, Sandblasting, Laser engraving

|

|

Steel

|

Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated

|

|

Aluminum parts

|

Clear Anodized, Color Anodized, Sandblasted Anodized, Chemical Film, Brushing, Polishing

|

|

Plastic

|

Plating gold (ABS), Painting, Brushing (Acrylic), laser engraving

|

3, Application

|

Agricultural equipment

|

Computing equipment

|

Automobile industry

|

Armament

|

|

Medical / dental instruments

|

Measuring instruments

|

Miscellaneous equipment

|

Textile equipment

|

|

Pharmaceutical industry

|

Pumps and general connections

|

Petrochemical industry

|

Safety equipment

|

|

Industrial valves

|

Fixing and movable equipment

|

Pharmaceutical industry

|

General machinery

|

|

Orthopedic implants

|

Food and beverage processing

|

Instrumentation equipment

|

Sanitary fittings

|

4, Technical Support

BERGER Group is a professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID,SketchUp. 3D max WORKS and other 2D & 3D software. We are able to design, develop, produce and deliver your PO according to your drawings, samples, or just an idea. control of non-standard products and OEM products.

5, Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(QC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(QC)

Packing & Delivery

|

Quantity(Pieces)

|

1 - 100000

|

>100000Est.

|

|

Est. Time(days)

|

14

|

To be negotiated

|

our service

refrigerator shelf bracket

lianxinda

produce Non-standard sheet metal deep drawing stamping parts. We are the professional manufacturer in producing metalstamping die, specialized in the manufacture of metal stamping mould about automotive parts, computer chassis, displays,communication equipment, office equipment and household appliances

|

Materials

|

carbon steel(cold rolled steel sheet,galvanized steel sheet or tube),stainless steel,copper,brass,aluminum,etc

|

|

Surface Treatment

|

All kinds of surface treatment is available: anodizing, zinc plating, black oxide, chrome plating, powder coating, ect

|

|

Equipment

|

stamping machines, automatic stamping machines,bending machines,welding machines,punching machines,meter

lathes,riveting,grinding,brushing |

|

Size

|

According to customer's design or samples

|

|

Mould

|

1.We make the toolings by ourselves according to customer's drawing or sample

2.Samples will sent to customer to confirm the quality and details 3.Lifetime: forever,we'll maintain the mould for free |

|

Confirm sample

|

If you are not satisfied with the first sample, we will modify the mould untill you are approval

|

|

Negotiation

|

The quality, quantity, price , delivery time , payment term,etc

|

|

Industries

|

Furniture hardware, electronic hardware, construction machinery parts, metal processing machinery parts

|

|

Packing

|

According to customer's requirement

|

|

Delivery

|

Delivery goods by sea or by air. According customer's requirement

|