NaN / 0

Powder Pressing Mold Custom Diy Eyeshadow Press

Get Latest Price

US$ 1000

≥2 Pieces

Quick Details

Shaping Mode:

Plastic Injection Mould

Place of Origin:

Guangdong, China

Brand Name:

Mr.Mould

Model Number:

PIM

Product Details

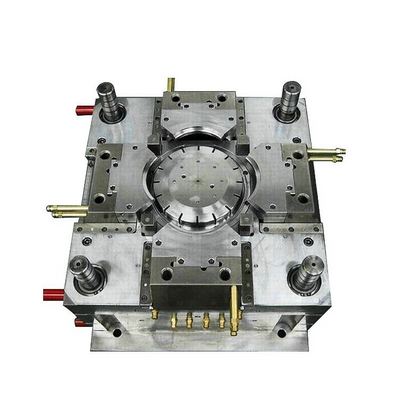

Powder Pressing Mold Custom Diy Eyeshadow Press

1. Trading Step:

2.Moulding & Fabrication

The mould making center equiped with CNC machines for precise moulds.Equiped with advanced CAD/CAM development and design system,a high-level designing and manufacturing team.

3.Mr.Mould General Mould For Reference

| In-house processing equipment available | NC milling machine |

| engraving machine | |

| EDM (Elctron Discharge Machining) | |

| wire cutting machine | |

| drilling machine | |

| grinding machine | |

| milling machine | |

| CNC processing center | |

| Solutions/services provided | mould design |

| mould fabrication | |

| and injection and blow moulding processing | |

| Selection of Materials | 718 |

| 718H | |

| P20 | |

| 2738 | |

| 2316 | |

| S136 | |

| Die carrier spec | 50S preharden > 30 HRC |

| Cooling system design | optimized recirculation cooling system, which improve productivity and reduce cost in process of production |

| Mid-stage treatment | hardening and tempering for improving hardness |

| Late-stage treatment | nitriding (hardness>45 HRC); vacuum hardening (hardness>50HRC) |

| Life span of mold | > 500,000 cycles (with regular service) |

| Packaging and handling | Once finished and passed inspection, moulds are properly packed with reinforced package for shipping, with rust prevention processed and mold lock installed |

| Warranty | all the moulds we manufactured are covered with one-year warranty after being delivered for service |

Advantages

1. Our R&D center contains 2 industrial designers, 4 structure designers, 2 electronic engineers,

18 professtional mold design engineers, 8 CNC programmers .

2. Our mold making center equiped with 8 sets high-precision CNC machines, 8 sets EDM machine

2 sets WEDM(SODICK), 1set mirror EDM, 15 sets coordinate milling machines.

3. Our plastic products processing center has 30 sets of sophisticated C injection molding machine

with a clamping force from 80 to 1080tons.

4. Advanced measurement equipment s- spectrograph(BRUKER), 2D Measuring Projector, CMM,

Surface Roughness Tester, Intellectual Hardness Tester, etc.

5. More than 15 -years experience.

6. ISO9001: certificated since 2008 year.

Packaging & Shipping

| Delivery time | 30 days after receipt the deposit |

| Packing |

Outside package : Standard wooden cases; Inner package : Stretch waterproof film & Each Mold painted anti-rust oil.3. Spare parts together with the mold shipment. |

Company information

Contact Information

|

Contract Person |

Harlow He |

|

|

|

|

Skype |

gzmrmould |

|

Tel: |

+86 20 3112 5303 |

|

Mobile(Whatsapp/Wechat): |

+86 13760789302 |

|

Website |

http://www.gzmrmould.com |