NaN / 0

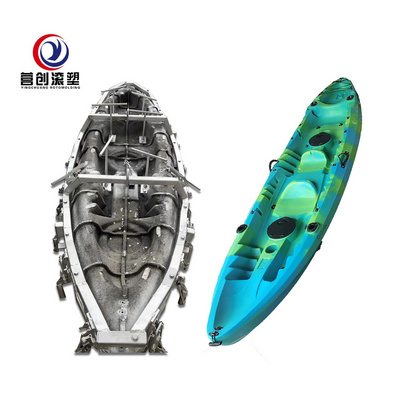

Rotomoulded Polyethylene Boat Plastic Boat Making Machine Rotomolding Machine

Get Latest Price

US$ 59999

≥1 Sets

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

yingchuang

Voltage:

400V

Power:

Advisory Service

Product Details

Product Description

Basic Processing Steps

(1).Charging the Mould (2).Heating the Mould (3).Cooling (4).Demoulding

1, Poura certain amount of powder raw materials into the mold, and merge the mold with screws or clamps.

2,Heat the mold and rotate it at 360 degrees in the oven; the raw material melts in the mold at 230-300degrees Celsius and evenly adheres to the inner surface of the mold to form the desired shape; heating time depend on the mould material,shape, weight and the raw material types.

3,At a certain time. after the heating is completed, the arm moves to the cooling station to start cooling,usually using air cooling and water mist cooling.When the mold surface is cooled to 80-90 degrees Celsius.

4,Stop the rotation of the arm and open the mold to complete molding process.

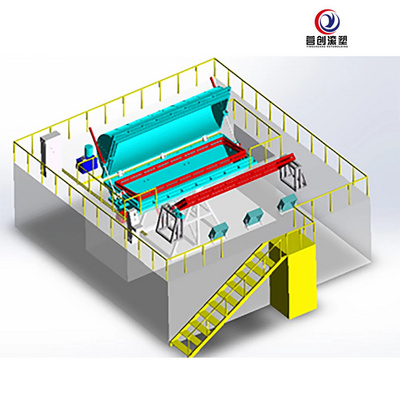

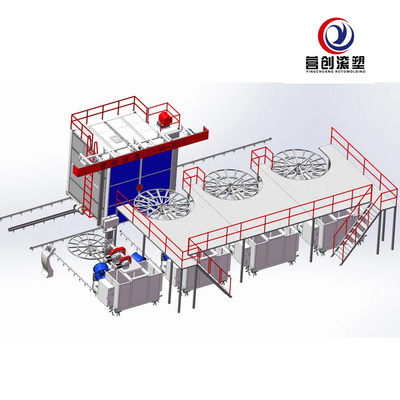

OVEN SWING ROTOMOLDING MACHINE

Oven Swing rotomolding machine is an extremely versatile and cost effective way of rotomolding large products and will take up very little floor space compared to other machines.Easy operation and no need high enough workshops.

Application:Suitable for production of large scale PE products such as water tank, huge bucket or groove, and boat...etc.

Heat Source:Natural Gas,Liquefied Gas or diesel oil.

High effective and thermal insulated of heating chamber low energy consumption.

Real-time monitoring the temperature of heating chamber to sure product quality.

Process formula can be storing,convenient for production management.

Touch interface with multiple functions is reasonable and easy to operate.

Breakdown self check,easier maintenance.

Remote fault diagnosis can be realized.

Easy to load/unloading the moulds to save both time and effort.

TFully automatic PLC control system,high production efficiency.

Specification

|

Model No

|

Floor Size

|

|

|

|

Biggest Tank made

|

|||

|

|

L(m)

|

W(m)

|

H(m)

|

Operation platform

|

|

|||

|

CO-1000

|

5

|

4.8

|

3.8

|

×

|

1000L

|

|||

|

CO-5000

|

5.8

|

5.6

|

4.2

|

×

|

5000L

|

|||

|

CO-10000

|

6.5

|

6.3

|

4.8

|

√

|

10000L

|

|||

|

CO-30000

|

7.8

|

7.3

|

5.1

|

√

|

30000L

|

|||

|

CO-50000

|

9.7

|

7.3

|

5.8

|

√

|

50000L

|

|||

Hot Searches