NaN / 0

High Energy Scale Herb Soil Grinding Fine Dry Micron Powder Grinder Milling Machine Planetary Industrial Ball Mill Laboratory

Get Latest Price

US$ 1600

≥1 Sets

US$ 1500

≥2 Sets

US$ 1128

≥4 Sets

Quick Details

Output (kg/h):

1 - 20 kg/h

Feeding Size (mm):

3 - 5 mm

Output Size (mesh):

1000 - 10000 mesh

Power (kW):

0.75

Product Details

Product Paramenters

High Energy Lab Scale Herb Soil Grinding Fine Dry Micron Powder Grinder Milling Machine Planetary Industrial Ball Mill

|

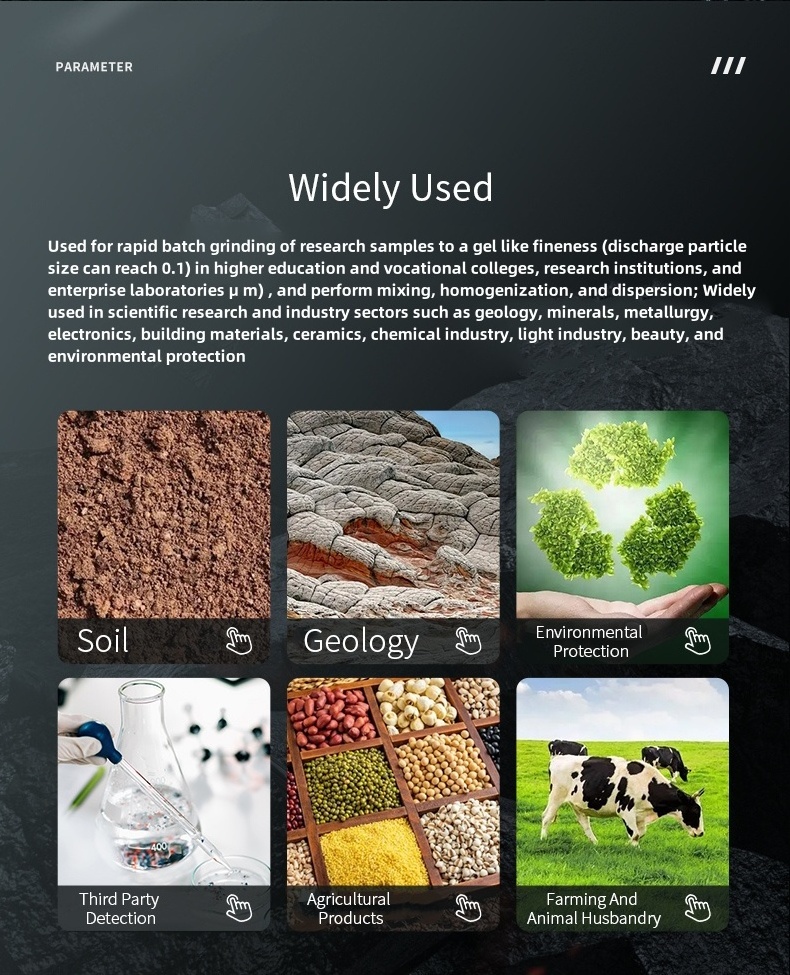

Application

|

Pulverizing, Mixing, Homogenizing, Colloidal Grinding, Mechanical Alloying, Mechanical Chemistry

|

|

|

|

Field of Application

|

New Energy, Geology/Metallurgy, Glass/Ceramics, Engineering/Electronics, Building Materials, Environment/Recycling, Agriculture,

Chemistry, Biology, etc |

|

|

|

Sample Characteristics

|

Soft, Hard, Brittle, Fibrous - dry or wet

|

|

|

|

Pulverization Principle

|

Impact, Friction

|

|

|

|

Maximum SampleSsize

|

< 5 mm, soil < 10 mm

|

|

|

|

Final particle size *

|

For colloidal milling, output < 0.1 µm

|

|

|

|

Number of Grinding Platforms

|

4 units

|

|

|

|

Grinding Method

|

Dry, wet, vacuum, atmosphere-protected grinding possible

|

|

|

|

Material of Grinding Jar

|

Stainless steel, tungsten carbide, zirconia, alumina, silicon carbide, silicon nitride, polyurethane, nylon, PTFE, onyx

|

|

|

|

Ratio Setting

|

1::2

|

|

|

|

Operating Modes

|

3 types: unidirectional, alternating forward and reverse, multi-stage

|

|

|

|

Programs Can Be Stored

|

15pcs

|

|

|

|

Time Setting

|

Intelligent screen digital setting, running/stopping time: 0-9999 minutes

|

|

|

|

Power Failure Protection

|

Power failure protection memory self-start function

|

|

|

|

Model

|

YXQM-0.4L

|

|

|

|

Grinding Jar Volume

|

50-100ml

|

|

|

|

Vacuum Jar Volume

|

50ml

|

|

|

|

Revolution Speed

|

5-450r/min

|

|

|

|

Rotation Speed

|

10-900r/min

|

|

|

|

Power(Watts)

|

0.55KW

|

|

|

|

Voltage & Frequency

|

Single Phase,220V/50Hz

|

|

|

|

Dimensions (WxDxH)

|

600x 400 x 5000mm

|

|

|

|

Weight

|

68kg

|

|

|

Products Description

Hot Searches