NaN / 0

306/304/316 Stainless Wire Rope, Galvanized Steel Wire Rope Sling for crane Cheap Price of Steel Wire Rope

Get Latest Price

US$ 0.17

≥10000 Meters

US$ 0.15

≥100000 Meters

Quick Details

Steel Grade:

steel

Type:

stainless wire

Grade:

316 steel/ stainless

Place of Origin:

China

Product Details

Product Description

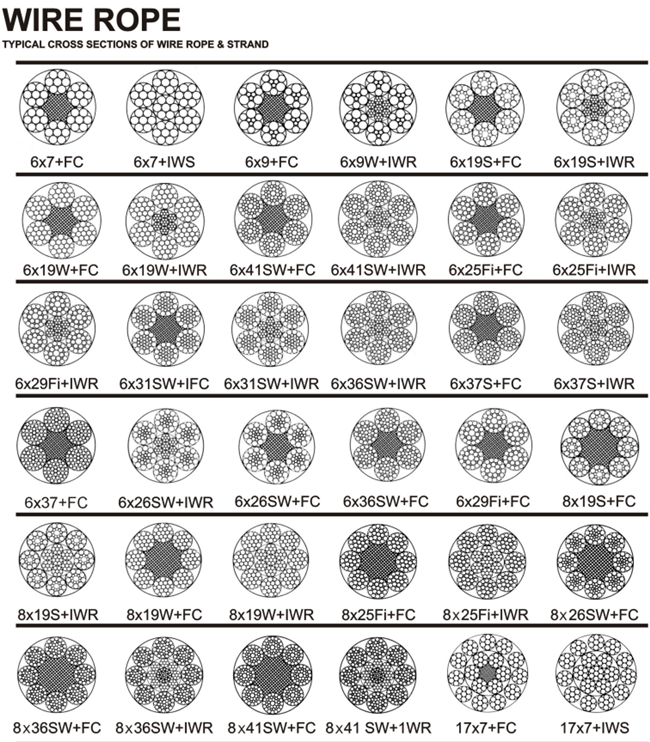

Wire rope is several strands of metal wire twisted into a helix forming a composite " rope ", in a pattern known as "laid rope". Larger diameter wire rope consists of multiple strands of such laid rope in a pattern known as "cable laid".

In stricter senses, the term "wire rope" refers to a diameter larger than 3/8 inch (9.52 mm), with smaller gauges designated cable or cords. [1] Initially wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure , flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators , and for transmission of mechanical power . Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 3/64 in. diameter while most wire ropes begin at a 1/4 in. diameter. [2] Static wire ropes are used to support structures such as suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Product Category

Product Category