NaN / 0

Mc Superior Water Jet Cutting Head Parts Micro Water Jet Cutting Machine Water Jet Cutting Machine

Get Latest Price

US$ 50000

≥1 Sets

US$ 30000

≥2 Sets

US$ 25000

≥3 Sets

Quick Details

Place of Origin:

Liaoning, China

Table Travel (Z) (mm):

200

Marketing Type:

New Product 2023

Cutting Accuracy(mm):

±0.1

Product Details

Contacts: Jone Tao

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: jonetao@dlmcmt.com

Mob/Whatsapp: +86 159 9867 7978

Fax: +86-411-39015062

Email: jonetao@dlmcmt.com

Mob/Whatsapp: +86 159 9867 7978

Products Description

Waterjet cutting machine

Waterjet cutting machine

Waterjet cutting machine is a cold cutting, dust-free, smokeless, non-toxic and odorless work, cutting speed, high precision, small and smooth incision. The equipment has been widely used in metal, ceramic, stone, automobile, aviation and other fields.

Waterjet cutting machine performance characteristics

1. The machine tool adopts cantilever structure.The X and Y lead rods are directly connected to the motor through the elastic coupling, absorbing vibration and providing higher transmission accuracy.

2. Can be loaded and unloaded in three directions.Overcome the gantry type machine tool can only feed from both ends and the blank material size is limited, cantilever machine can be placed than the size of the cutting platform blank.

3. In the process of operation, the two sides of the gantry machine tool screw feed is not synchronized and the fabric pressure is not uniform resulting in machine damage and can not guarantee the cutting accuracy.

4. High quality servo drive system is adopted, and the screw guide is adopted by international famous brand to ensure the smooth transmission of the whole machine.

5. Quick cut, smooth cut, no dust, no thermal deformation, no pollution, reduce material waste and other characteristics.

The bed is separated from the cutting platform.Not affected by vibration during cutting, improve the cutting accuracy.

2. Can be loaded and unloaded in three directions.Overcome the gantry type machine tool can only feed from both ends and the blank material size is limited, cantilever machine can be placed than the size of the cutting platform blank.

3. In the process of operation, the two sides of the gantry machine tool screw feed is not synchronized and the fabric pressure is not uniform resulting in machine damage and can not guarantee the cutting accuracy.

4. High quality servo drive system is adopted, and the screw guide is adopted by international famous brand to ensure the smooth transmission of the whole machine.

5. Quick cut, smooth cut, no dust, no thermal deformation, no pollution, reduce material waste and other characteristics.

The bed is separated from the cutting platform.Not affected by vibration during cutting, improve the cutting accuracy.

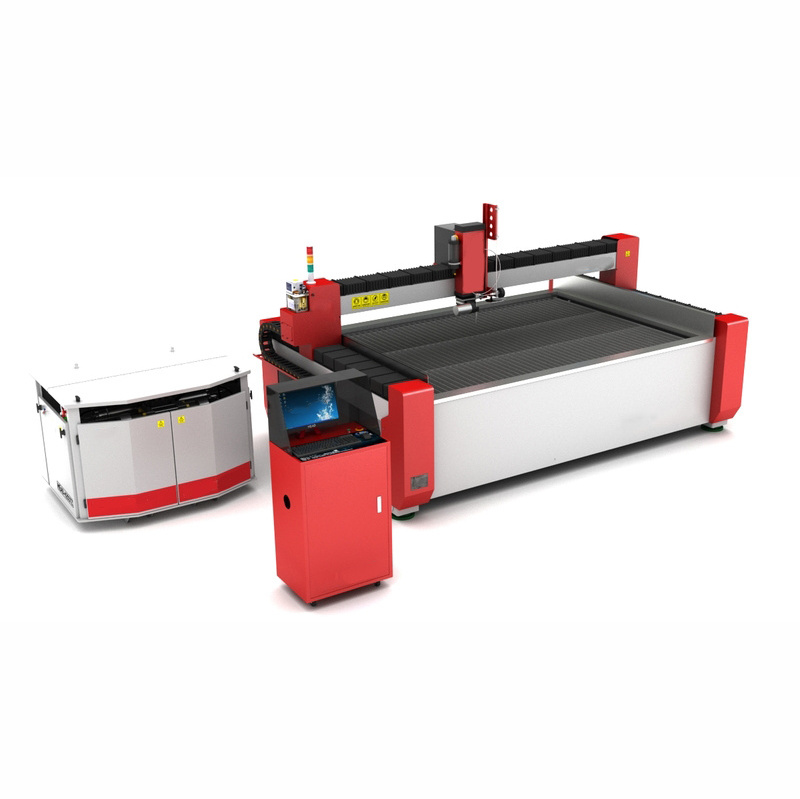

Gantry type

Name: Water cutting machine

Brand: MC

Original: China

Name: Water cutting machine

Brand: MC

Original: China

Gantry water jet cutting machine is currently applicable to the most material cutting process; A wide range of cutting materials (metal, glass, stone, composite materials, etc.) Cold cutting, no thermal effect, no need for secondary processing Can cut any straight line, curve, graph, flexible and convenient The slit width is only 1-1.5mm, the cutting surface is smooth without burr, and the roughness is up to 3.2μm-1.6μm Workpiece without special clamping, easy to operate; Wide cutting range, metal cutting thickness up to 150mm.

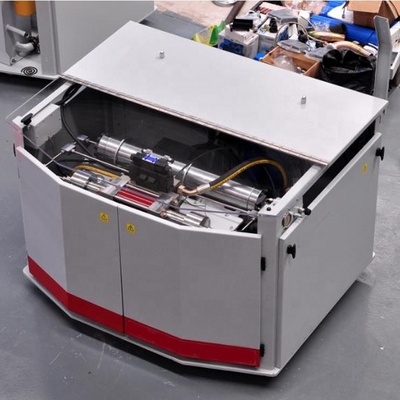

Machanical arm type

Name:

Mechanical arm water jetting machine

Brand: MC

Original: China

The Mechanical arm water jetting machine through the pre-edited program of the control system. It is generally composed of three parts: themotion system, the guiding device and the arm.

Cantilever type

Name:

Cantilever

water jet cutting machine

Brand: MC

Original: China

Standard cantilever water cutting platform, the cutting platform adopts split cantilever design. The Y-axis side frame is made of welded concrete, which has a stable structure. The X-axis adopts one-time extruded 8mm aluminum alloy, which is light in weight and high in rigidity, and the weight is only half of that of traditional materials. Cantilever water jet cutting machine space for loading and unloading is large, and it can be loaded and unloaded from three sides, which is easy to operate and occupies a small area.

Product Paramenters

|

SPECIFICATIONS FOR WATERJET CUTTING MACHINE

|

|

|

|

Working table size

|

1.2m×1.2m 1.5m×1.5m 2.0m×1.5m 2.5m×1.5m

3.5m×1.5m 4.0m×1.5m 3.0m×1.8m 4.0m×1.8m

|

|

|

Cutting accuracy

|

±0.1mm

|

|

|

Repeating accuracy

|

±0.02 mm

|

|

|

Running speed of X axis

|

0—20000mm/min

|

|

|

Running speed of Y axis

|

0.75KW

|

|

|

Running speed of Z axis

|

0—1000mm/min

|

|

|

Motor power of Z axis

|

0.20KW

|

|

|

Z axis Stroke

|

200mm

|

|

|

Motor

|

Panasonic AC Servo

|

|

|

Running part

|

Screw Mandrel and Lead Rail brand named HIWIN, ensure the running speed up to 20000mm/min

|

|

Recommend Products

Hot Searches