Just tell us the following parameters, we will match proper model for you:

(1)What is your application occasions ?

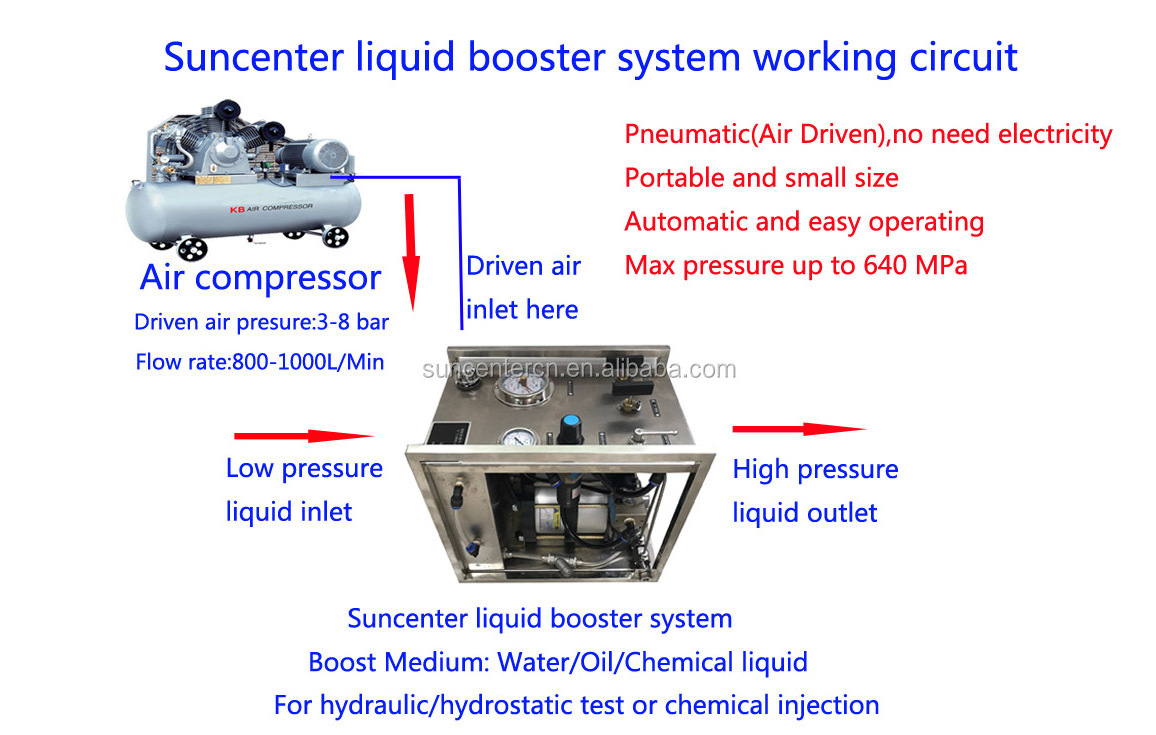

For hydraulic test or Chemical reagents injection?

(2) What is the max outlet working pressure do you need? ( )bar

(3) What outlet flow do you need? ( ) L/min