NaN / 0

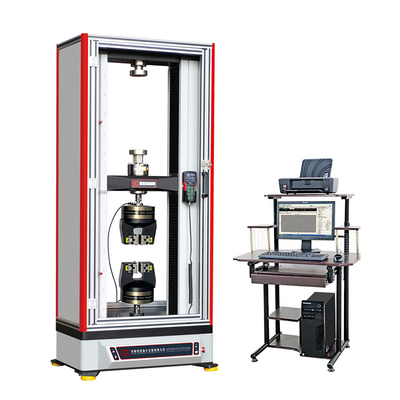

Digital Display 1000kN Stand Hydraulic Valve Test Bench

Get Latest Price

US$ 3000

≥1 Sets

Quick Details

Warranty:

1 year

Power:

Electronic

Place of Origin:

Guangdong, China

Brand Name:

Lixian

Product Details

Digital display 1000kN Stand Hydraulic Valve Test Bench

Product Description

Equipment Introduction :

The Stand Hydraulic Valve Test Bench used to a variety of metal materials, tensile, compression, bending, shearing accompanied by increased shear test can be done, can be used as plastic, concrete, cement and other non-metallic materials, compression tests, with simple accessories to complete the chain tape , wire, welding rod, tile's wide range of performance tests and components.This machine adopt under the fuel tank-mounted machine, low profile, light weight, especially for the engineering construction sector.

Main technical specifications :

|

Max load KN |

100 |

300 |

600 |

1000 |

|

|

Range |

whole journey didn't sub-file ,equivalent 3 grade |

|

|||

|

Test force measuring range KN |

4%-100%FS |

|

|||

|

Test Force showed the relative error |

≤indicating value±1% |

||||

|

Test Force Resolution |

0.01kN |

||||

|

Displacement measurement resolution mm |

0.01 |

||||

|

Max tensile test space mm |

550 |

650 |

750 |

|

|

|

Max compression space mm |

380 |

460 |

|

||

|

Diameter of round specimen clamp jaw mm |

Φ6-Φ26 |

Φ13-Φ40 |

|

||

|

Thickness of flat specimen clamping jaws mm |

0-15 |

0-15/15-30 |

|

||

|

Maximum clamping width of the flat specimen mm |

70 |

75 |

|

||

|

Maximum clamping width of the flat specimen(Column number) |

2 |

2/4 |

|

||

|

Clamping method |

Manual clamping |

Automatic clamping/Manual clamping |

|

||

|

Shear specimen diameter mm |

10 |

||||

|

Upper and lower compression plate size mm |

Φ160(option 204×204) |

||||

|

The maximum distance between the fulcrum bending |

450 |

||||

|

Space stretching from the two pillars distance |

450 |

550 |

|

||

|

Pump motor power KW |

1.1 |

|

|||

|

Beam moves up and down motor fixed rate KW |

0.75 |

|

|||

|

Net weight Kg |

1600 |

1800 |

2000 |

2600 |

|

Host :

The Stand Hydraulic Valve Test Bench adopt oil cylinder under mounted type host, stretching space is at the top of host, compression test space is between the at the work table and the crossbar .

Transmission system:

Down beam go up and down by the use of motor reducer, chain drive mechanism, vice screw drive, to achieve tensile, compression of space to adjust.

Hydraulic System:

The oil tank is sucked through the filter screen and be inhaled pump oil ,through the petroleum pipeline of oil pump transport to oil valve,When the hand wheel to send off the oil, due to the role of oil will push the piston, the oil from the return pipe to tank, when the hand wheel to open get the oil, then the working fluid into the fuel tank through the tubing, pressure tubing through and through oil return valve to tank.

Control system:

Electronic force measurement, liquid crystal display test force - time curve, test power, peak test power, has obvious characteristics of the material yield strength yield the experimental data easy and intuitive;

Through digital button input sample numbers, cross-sectional area, can be directly measured the material tensile strength, yield strength and other mechanical properties; can query the experimental results, print (with micro-printer)

Safety protection device:

a) When the test force more than 3% of the maximum test force, the overload protection, oil pump motor shut down.

b) When the piston rises to the upper limit position, stroke protection, pump motor shut down.

Fixture: Whole set fextures include:stretch fixture,compression fixture,bending fixture.

Hot Searches