NaN / 0

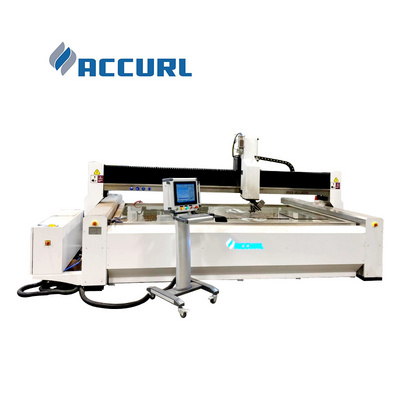

Waterjet waterjet cutting machine APW high accuracy CNC water jet cutting machine

Get Latest Price

US$ 45000

≥1 Sets

Quick Details

Place of Origin:

China

Brand Name:

APW

Voltage:

380V

Rated Power:

37KW

Product Details

Product Description

CNC water jet cutting machine is made up of several key components, such as intensifier pump; cutting table ; CNC controller; auto abrasive delivery system.

The technical parameters for CNC water jet cutting machine showing in the following picture:

Dual-Core Waterjet Debut

APW pioneered “Dual-Core” waterjet, which integrated SIEMENS motor, imported REXROTH hydraulic pump and hydraulic valves assembly, American A&V intensifier, American high pressure tube and stainless steel water tank. This dual intensifiers design (for cnc water jet cutting machine ) represents another landmark in APW history.

They has been widely used in all APW cnc water jet cutting machine series. UP to now, APW is still the only water jet cutting machine manufacturer holding this advanced technology in China.

Imported components

We adopt the imported component for CNC water jet cutting machine like Rexroth hydraulic pump; USA intensifier; Siemens motor;Omron PLC; Yaskawa servo drive; Yuken direction control valves etc. The whole parts of Intensifier are assembled in USA (not just some parts), most of the smaller parts are also imported from USA to ensure its good stability during cutting, durability and long working service life.

Hot Searches