NaN / 0

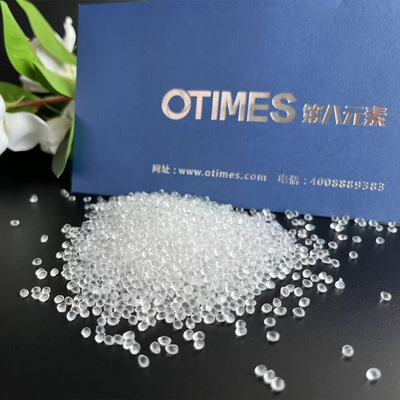

TPU Resin Granules Polyurethane Plastic Raw Material Injection Moulding Grade for Case

Get Latest Price

US$ 1900

≥1 Pieces

US$ 1650

≥5 Pieces

Quick Details

Place of Origin:

Shandong, China

Brand Name:

Miracll

Model Number:

E390

Color:

100% Transparent

Product Details

Product Description

TPU thermoplastic polyurethane elastomer (Thermoplasticpolyurethanes) name for rubber.

It is mainly divided into polyester type and polyether type. It has a wide range of hardness (60ha-85HD), oil resistance, transparency and good elasticity. It is widely used in the fields of daily necessities, sporting goods, toys, decorative materials and so on. The so-called elastic body refers to the glass temperature is lower than the chamber temperature, breaking elongation >50%, after the removal of external force recovery is better polymer material. Polyurethane elastomer is a special kind of elastomer, polyurethane elastomer has a wide range of hardness and performance, so polyurethane elastomer is a kind of polymer material between rubber and plastic. Thermoplasticized, chemically with little or no crosslinking, and almost linear molecules with some physical crosslinking. This type of polyurethane is called TPU. Main advantages: excellent adhesion; Low viscosity. Good flexural resistance; High gloss; Excellent weather resistance.

As an elastomer, TPU is a material between rubber and plastic, which can be seen from its rigidity, which can be measured by elastic modulus. The elastic modulus of rubber is usually 1~10Mpa, TPU10~1000Mpa, and plastic (nylon, ABS, PC, POM) is 1000~10000Mpa. TPU has a wide hardness range from ShoreA60 to ShoreD80 and has high elasticity throughout the hardness range. TPU is flexible in a wide temperature range of -40~120℃ without the need for plasticizers; TPU has good resistance to oils (mineral oils, animal and vegetable fats and lubricants) and many solvents; TPU also has good weather resistance and excellent high-energy ray resistance. It is well known that tear resistance and flexure strength are excellent; High tensile strength, high elongation, low long-term compression deformation rate are the significant advantages of TPU.

TPU E390 Miracll 90 degree polyurethane elastomer 90ATPU granules.

Performance characteristics: special wear resistance, oil/solvent resistance, high rebound, high pressure resistance, excellent mechanical properties

Application: Conveyor belt, pipe, sealing ring, cable, blending modification, auto parts, blending modification, auto parts, casters, shoe materials, packaging, etc

Mirathane® TPU E3 series

Mirathane® TPU E3 series product model list

E375 E380 E385 E390 E395 E355D E365D E375D

Properties: good processability, short molding cycle, no precipitation, high transparency, easy to spray and electroplate

Application: electronic product jacket, shoe material, blending modification, casters, pneumatic tube, adhesive bag, shoulder strap, anti-slip chain, etc

| Project Performance | Test Conditions[Status] | Test Method | Test Data | Data Unit | |

| Physical properties | proportion | ASTM D792 | 1.12 | g/cm3 | |

| Mechanical properties | Hardness tester | Shaw A, 23℃, 2.00 mm, Injection molding | ASTM D2240 | 88 - 92 | |

| Resistance to Taber wear | 23℃, 1000 Cycles, 1000 g, H-22 runner | ASTM D1044 | 30.0 | mg | |

| Tensile stress | 100%strain, 23℃, 2.00 mm | ASTM D412 | 9.00 | MPa | |

| Tensile strength | yield, 23℃, 2.00 mm | ASTM D412 | 46.0 | MPa | |

| elongation | fracture, 23℃, 2.00 mm | ASTM D412 | 480 | % | |

| Tear strength | 23℃, 2.00 mm | ASTM D624 | 123 | kN/m | |

| Compression permanent deformation | 70℃, 22.0 hr | ASTM D395 | 40 | % | |

| Rebound Resilience | 23℃, 2.00 mm | 55 | % | ||

| Thermal performance | Glass conversion temperature | DSC | -55.0 | ℃ | |

| Veka softening temperature | ASTM D1525 | 114 | ℃ | ||