NaN / 0

YUDA 5 gallon plastic water bottle lebeler machine making machine

Get Latest Price

US$ 95000

≥1 Sets

US$ 60000

≥5 Sets

Quick Details

Neck Diameter(mm):

30 mm

Max.Bottle Diameter(mm):

20 mm

Max.Bottle Height(mm):

200 mm

Bottle Volume(ml):

2000 ml

Product Details

Products Description

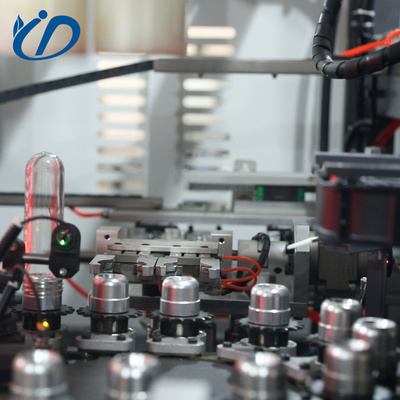

Fully automatic blow molding machines

can produce a variety of shapes and sizes of plastic bottles and containers, including round, square, oval, and more. They are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and cleaning products, among others, and play an important role in modern industrial production.

Yuda fully automatic blow molding machines

are

efficient, precise, high-quality, and reliable production equipment

,

and their advanced technology and automation systems

make them a preferred choice for many manufacturers.

Yuda can blow bottles include

Yuda can produce various shapes and sizes of plastic bottles and containers

, including but not limited to:

-

Round Bottles:

Fully automatic blow molding machines can produce round bottles in various shapes and sizes, such as water bottles, juice bottles, soda bottles, etc.

- Square Bottles:

Fully automatic blow molding machines can also produce square or rectangular bottles, which are commonly used for shipping liquid detergents, cleaning agents, soap solutions, etc.

- Oval Bottles:

Fully automatic blow molding machines can produce oval-shaped bottles, which are commonly used for personal care products such as cosmetics, body washes, shampoos, etc.

- Irregular-Shaped Bottles:

In addition to the above shapes, fully automatic blow molding machines can also produce bottles with unique shapes, such as flat bottles, triangular bottles, hexagonal bottles, etc.

In reality, we can produce many different shapes and sizes of bottles, depending on its design and configuration.

If you have any questions, please contact us.

Product Paramenters

|

Model

|

Center distance

|

Output

|

|

YDBA-1L-2

|

76.2mm

|

1800-2200

|

|

YDBA-2L-2

|

114.3mm

|

1500-2000

|

|

YDBA-1L-4

|

76.2mm

|

3600-4200

|

|

YDBA-2L-4

|

114.3mm

|

3000-3800

|

|

YDBA-1L-6

|

76.2mm

|

5000-6000

|

|

YDBA-2L-6

|

114.3mm

|

4500-6000

|

|

YDBA -5L

|

190.5mm

|

700-1000

|

|

YDBA-10L

|

190.5mm

|

600-700

|

|

YDBA-20L

|

|

500-600

|

|

YDBA-5L2

|

220mm

|

1500-1800

|

|

YDBA -10L2

|

|

1200-1400

|

Product Details

Preform Loading

The preforms are loaded into the hopper of the machine's loading system, which can hold hundreds or even thousands of preforms depending on the size of the machine.

Heating

Once the preforms are loaded, they are transported to the heating station where they are heated to the required temperature using infrared heating lamps. The temperature and duration of the heating process are carefully controlled to ensure that the preforms are heated evenly and not overheated.

Stretching

Next, the preforms are transferred to the stretching station where they are stretched using a stretching rod. This process ensures that the preforms are the correct length and diameter for blowing.

Blowing

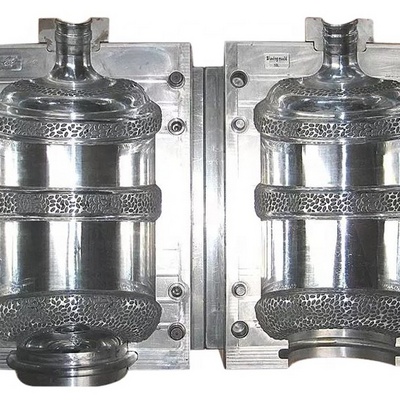

Once the preforms are properly stretched, they are moved to the blowing station where high-pressure air is used to blow the preforms into the desired shape. The molds can be quickly and easily changed to produce different bottle shapes and sizes.

Cooling and Ejection

After the bottles are blown into their final shape, they are cooled using chilled water or air before being ejected from the machine. The cooling process ensures that the bottles maintain their shape and do not deform due to heat.

Quality Inspection

Finally, the bottles are inspected for quality control purposes. Any defective bottles are removed from the production line, and only the bottles that meet the required quality standards are allowed to proceed to the next stage of the production process.

Yuda Workshop

More Products

Hot Searches