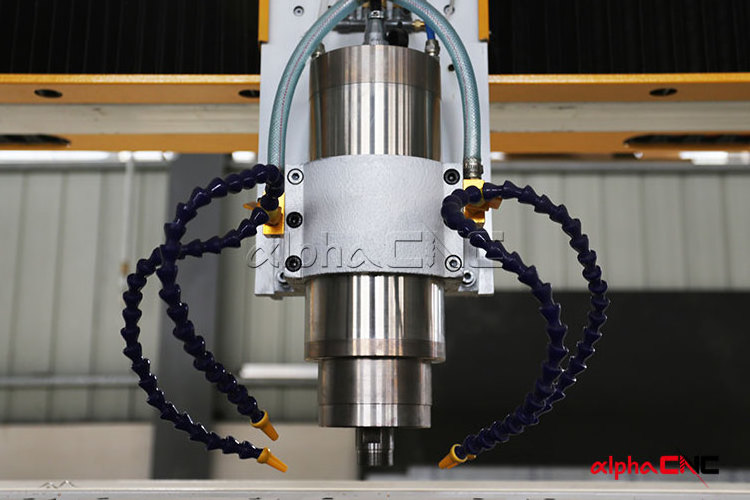

The M Series machine comes standard with a 5.5kw high frequency water cooling spindle. And is fully programmable with speeds from 6000 to 24000 RPM.

Cheap Price CNC Sink Hole Cutting Machine Marble Quartz Granite CNC Stone Router Machine Stone Cutting Engraving Polishing

This machine is specially developed by AlphaCNC for small and medium stone processing plants. Especially for companies that need multi-functional affordable machines.

This machine is a versatile machine that can do traditional work such as lettering, engraving, cutting, drilling and so on. It is worth noting that in order to meet the customer's demand for processing stone countertops, Alpha has improved the machine, such

as: lengthening the gantry beam to facilitate workers to load and unload the workpiece. The vacuum pump and vacuum cups are added to raise the workpiece and vacuum suck the workpiece. This allows the machine to process the sides of the slab, such as cutting, shaping, and polishing the sides of the workpiece.

The machine can do the following work: Countertops, Sink hole, shower trays, bas-reliefs, funeral tablets/gravestones, commemorative plates, Furniture, Fireplace.

★Type heavy duty Machine structure, good weight bearing capacity, not easy to deformation, the special machine bed design, can bearing more than 2000kgs materials.

★ The special designed Zaxis, can increase the stone relief accuracy, can solve the Zaxis belt or ball screw breaking problem thoroughly.

★ The water proof and dust proof system for X Y Zaxis, can protect all the parts, reduce the machine fault, enlarge the life time.

★ High-performance driven motor to ensure that the machines high speed and accuracy.

★ Using well-known domestic brands of water-cooled brushless spindle, low noise, strong cutting ability, to ensure the long time working.

★ Automatic tool calibration easy and accurate "Z" zero position for single and multiple tool changes

★ Easy to use Mach 3 controller works with all industry standard CAD/CAM software

★ High grade Hiwin square rail

★ XY axis German helical rack and pinion

★ Z axis high precision TBI ball screw

★ 900*1500mm, 1300*1800mm, 1300*2500mm, 1500*3000mm,1800*2500mm standard sizes (Special sizes available upon request.)

★ 1 spindle, 2 spindles or 3 spindles available upon request.

|

Parameters

|

Standard SpecificationsASC-3015-MTC

|

|

X,Y,Z Working Area for Panel

|

2500*1300*300mm/3000*1500*300mm

|

|

Spindle Power

|

5.5KW Powerful Water Cooling Spindle

|

|

0.1 X,Y,Z Traveling Positioning Accuracy

|

0.1mm

|

|

Table Surface

|

Steel

|

|

X,Y,Z Rail and Transmission

|

X/Y Helical German rack and pinion

Z High precision TBI ball screw |

|

Max. Rapid Travel Rate

|

30,000mm/min

|

|

Max. Working Speed

|

20,000mm/min

|

|

Drive Motors

|

Yako or Leadshine

|

|

Working Voltage

|

380V 3 phase or custom made.

|

|

Command Language

|

G code

|

|

Operating System

|

Mach3( DSP, Nc-studio, Syntec, Siemens, etc. for option)

|

|

Interface

|

USB

|

|

Software capabilities

|

Vectric Aspire, Type3, Ucancam, Artcam, AlphaCam, Powermill,etc.

|

|

Running Environment

|

Temperature: 0℃~45℃

Relative Humidity: 30%~75% |

The M Series machine comes standard with a 5.5kw high frequency water cooling spindle. And is fully programmable with speeds from 6000 to 24000 RPM.

The machine adopts Taiwan Hiwin square rail, which is more than twice durable. And the use of high quality helical rack pinion, makes it powerful.

All the electrical components are housed and wired in a electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet. In addition, the cabinet serves as a work bench for the tools required.

The machine comes with a 7.5kw vacuum pump for the sucking the stone, it is powerful enough for suck the machine on the table.

Easier to load the material

|

Packaging

|

|

|

|

Size

|

2300(L) * 3700(W) * 1900 (D)

|

|

|

Weight

|

1.5T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Alpha CNC Co., Ltd. is a factory that specialized in manufacturing and exporting all kinds of cnc routers, such as cnc router machine center with automatic tools changer, multi-process cnc router, multi-head relief cnc router, 3D (Three-dimensional) cylindrical material carving and milling cnc router. We also produce laser engraving cutting machine, fiber laser marking machine, plasma metal cutting machine, waterjet cutting machine and letter bending machine etc. All machines are approved by ISO9001:2008 and CE. We have exported our machines to more than 50 countries, such as USA, Germany, Italy, Canada, Spain, India, Egypt, France, Russia, Brazil, Mexico, Belgium, Chile, South Korea, Uzbekistan, Vietnam, Southeast Asia, and so on.

Anyone is interested in our product, welcome to be the partner of Alpha.

FAQ.

Q1: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by "Team viewer"online, with telephone or Skype explain.

Q2: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q3 :How can I trust your company and your products?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. The testing video and pictures will be available before delivery.

Q4.If machine have any problem after I ordered it, what could I do?

Free parts send to you in machine warranty period if machine have any problem. Free after-sales service life for machine, please feel free contact us if your machine have any problem. We will give you 24hours service from phone and skype.

Q5. Can I visit your factory?

Yes! We greatly welcome customers to visit our factory!

Q6. What's your date of delivery?

For standard machine, about 15 working days; For customized machine, about 20 working day.

Q7.MOQ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.