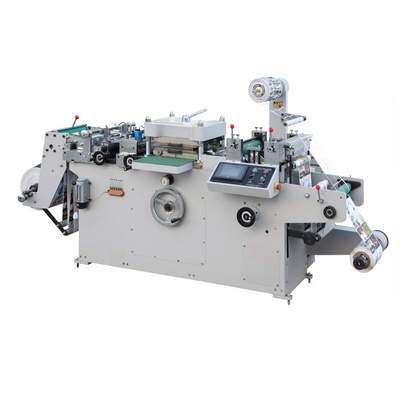

It uses an accurate rotary die-cutting system and performs material conversion through micro-control. Die cutting, waste rewinding and finished product rewinding are all in one process. Main control PLC and man-machine interface, with functions such as edge detection and watch detection. The cutting system uses magnetic powder clutch and magnetic powder brake to control the synchronization of cutter and die cutting. Separate waste motor control.