NaN / 0

Apple juice processing plant apple juice extractor machine industrial apple juicer machine

Get Latest Price

US$ 49900

≥1 Pieces

Quick Details

Place of Origin:

Shanghai, China

Brand Name:

Beyond

Type:

Fruit processing machine

Voltage:

220V/380V/415V

Product Details

Apple juice processing plant apple juice extractor machine industrial apple juicer machine

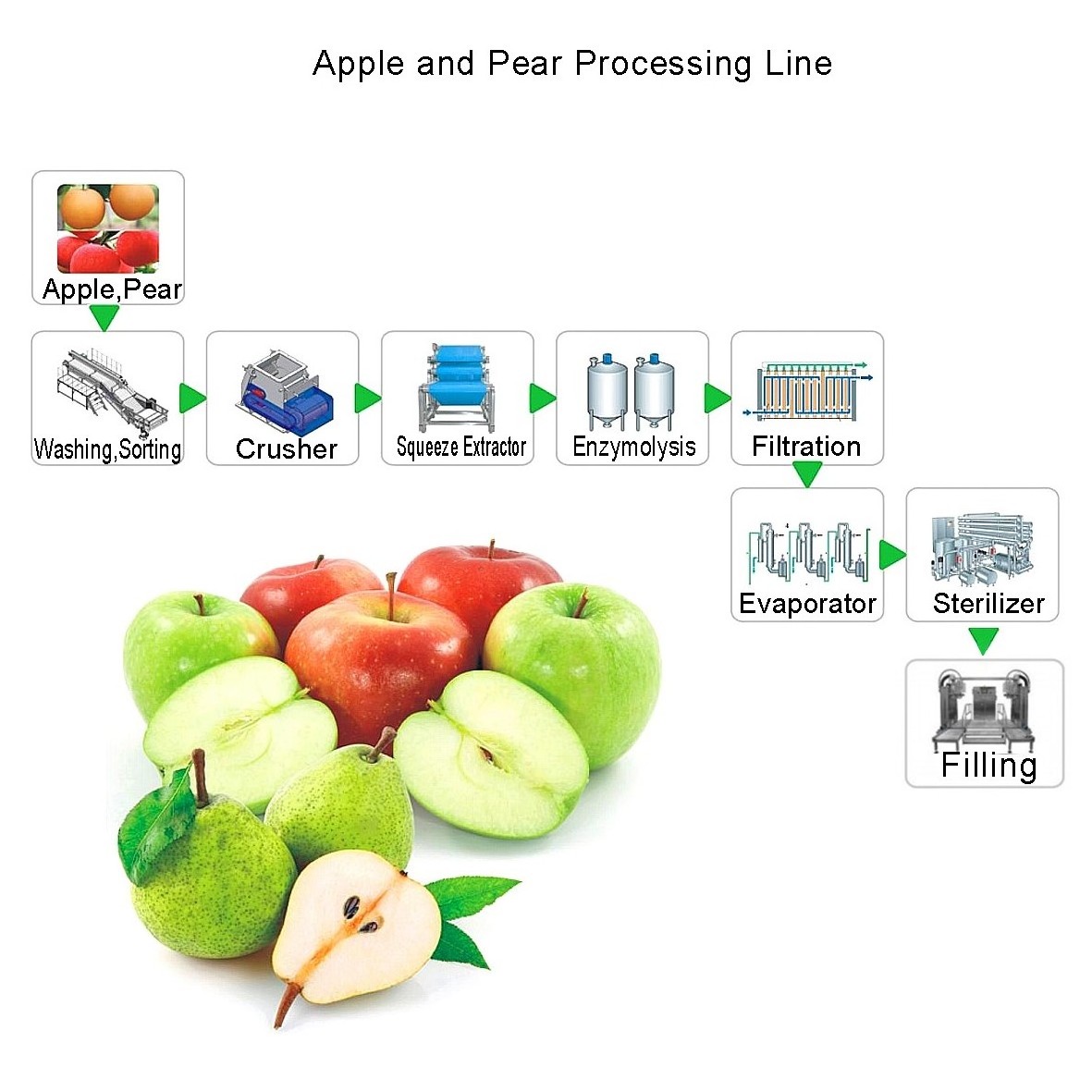

Apple juice processing plant is a factory that specializes in extracting juice from apples and processing it. The following is the general process of an apple juice processing plant:

1.

Purchasing and receiving apples

: Apple juice processing plants will purchase fresh apples from farms or suppliers. When receiving apples, quality checks are conducted to ensure that the maturity and quality of the apples meet the requirements.

2.

Cleaning and Peeling

: Apples need to be cleaned before entering the processing process to remove surface dirt and impurities. Subsequently, apples may need to undergo peeling treatment to remove the skin.

3.

Cutting and peeling

: After cleaning and peeling, the apple will be cut into small pieces to facilitate subsequent juice extraction and processing. If it is necessary to produce apple juice without pulp, it also needs to be de pitted.

4.

Juicing

: The cut apple chunks will be fed into a juicer and separated from the juice by pressing or centrifugation. This process can yield pure apple juice.

5.

Filtering and concentration

: The liquid after juice extraction may still contain fruit residue or other impurities, which need to be filtered through filtering equipment to remove impurities. If concentrated apple juice is needed, an evaporator can be used to evaporate the water, making the juice more concentrated.

6.

Sterilization and filling

: In order to ensure the safety and shelf life of apple juice, it is necessary to sterilize the juice. Common methods include heat treatment and high-pressure treatment. The processed apple juice will be filled into bottles, cans, or other packaging containers.

7.

Packaging and storage

: The filled apple juice will be packaged, usually with product information and shelf life indicated on the label. Then, the apple juice will be stored under appropriate temperature and humidity conditions to maintain its quality and taste.

In addition to the basic processes mentioned above, some apple juice processing plants may also carry out other processing steps, such as adding seasoning agents, vitamins, etc., to increase the taste and nutritional value of the products. Meanwhile, some manufacturers also conduct quality control and testing to ensure that their products comply with relevant food safety standards and regulatory requirements.

The highlights of the apple processing line include the following aspects:

1.

High degree of automation

: Modern apple processing lines adopt advanced automation equipment and technology, which can achieve a series of automated operations from apple sorting, cleaning, cutting, peeling, and core removal. This not only improves production efficiency, but also reduces labor costs and human errors.

2.

High precision

: The apple processing line is equipped with high-precision sensors and control systems, which can accurately detect and sort apples. Through techniques such as image recognition and weight measurement, accurate judgment of the size, quality, color, and other characteristics of apples can be achieved, thereby achieving refined processing and grading.

3.

High efficiency

: The apple processing line can achieve continuous and efficient production processes, greatly improving processing efficiency. By optimizing equipment layout and arranging process flow reasonably, downtime and conversion time in production can be minimized to the greatest extent, thereby improving production capacity and reducing production costs.

4.

Product diversity

: Modern apple processing lines can flexibly adjust processing methods and parameters according to market demand and customer requirements, producing various specifications and forms of apple products. Whether it's slicing, dice, puree, or juice, they can all be completed on the same production line, achieving diversified product supply.

5.

Hygiene and safety

: The apple processing line emphasizes hygiene and safety, using materials and designs that comply with food hygiene standards. The surface of the equipment is smooth and easy to clean, which can effectively prevent bacterial growth and cross contamination. At the same time, thoroughly clean and disinfect the apples during the processing to ensure the safety and hygiene quality of the products.

In summary, modern apple processing lines have improved production efficiency and product quality through automated, precise, and efficient processing methods, meeting diverse market demands, and emphasizing hygiene and safety, providing consumers with safe and reliable apple products.

The main products of apple juice processing plants are apple juice and related products. Specifically, the following is a list of possible products:

1.

Pure apple juice

: This is the most basic product, which is made from fresh apples through processes such as juice extraction, filtration, and sterilization.

2.

Concentrated apple juice

: By removing some moisture, the apple juice is concentrated, making it convenient for storage and transportation.

3.

Sugar free apple juice

: No sugar is added during the production process, suitable for people who need to limit sugar intake.

4.

Organic apple juice

: The juice made from organically grown apples meets organic food standards.

5.

Mixed fruit juice

: Mix apple juice with other fruit juices to create a variety of flavors of fruit juice products.

6.

Apple beverage

: Adding other ingredients such as carbonated water, spices or seasonings to apple juice to make soda, fruit flavored drinks, etc.

7.

Apple Jam

: Boil apples and add sugar to make jam, which can be used for seasoning bread, cookies, and other foods.

8.

Dried apples

: Dried fruits made by slicing or cutting apples and dehydrating them, which are convenient to carry and store.

Technical Data For apple processing line

| Brand Name: | Shanghai Beyond |

| Model Number: | BY-AL |

| Capacity | 5-50T/H |

| Raw material | Fresh apple/pear |

| End product | NFC fresh apple/pear juice, concentrated apple/pear juice, clear apple/pear juice |

| Juice yield | 60-75% |

| Fresh fruit input brix | 10-12brix(for fresh fruit) |

| End product output brix | 65-72Brix |

| Package for end product | Aseptic large bag in drum/ glass bottle/PET bottle, Roof type carton box/ brick shape carton |

| Certification: | ISO9001/CE/SGS |

| Main material for machines | SUS304 or SUS316 |

| Place of Origin: | China |

| Manufacturer history | More than 10years |

| Voltage | 380V 50Hz/110V 60hz/415V 50Hz |

| Power consumption(Kw) | energy saving type, about 100-500kw, |

| Operator needed | About 6-20persons |

| Cooling water consumption | About 80-300M 3 |

| Steam consumption | About 300-5000T/H, |

| Factory space needed | About 500-5000Sqm |

| Warranty | 12 months after commissioning |

|

After sales service |

Engineers available to service machinery overseas |

Project samples

| No. | Project information | Place | Remark |

| 1 | 5 t/H pear juice production line | Hebei Cangzhou | Turnkey project |

| 2 | 5 t/H apple vinegar production line | Shandong yantai longkou | Sterilization and after-filling equipments |

| 3 | 10 t/H fruit juice with fruit grain production line | Beijing | Turnkey project |

| 4 | Concentrated fruit juice production line |

Fujian Sanming |

Original fruit pre-process project |

| 5 | 12000 p/H wild papaya beverage production line | Guizhou zunyi | Turnkey project |

Our Services

Pre sales services

After-sale service

1.

Equipment warranty period

: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2.

Maintenance and upkeep services

: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3.

Accessory supply

: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4.

Training services

: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5.

Installation and debugging

: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.

Hot Searches