NaN / 0

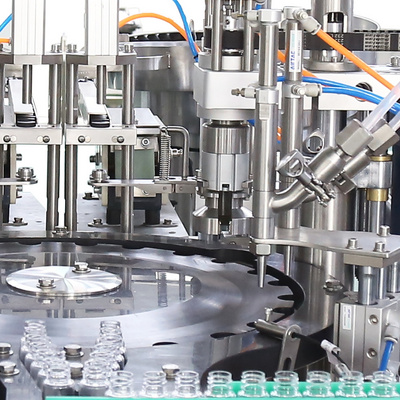

New Design Automatic Cream Lotion Liquid Cosmetic Filling Machine Filling Packing Production Line

Get Latest Price

US$ 13900

≥1 Sets

US$ 9900

≥5 Sets

US$ 6900

≥10 Sets

Quick Details

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

Packaging Material:

Wooden Case

Filling Material:

Other, Water, Oil, Powder, Cosmetic

Filling Accuracy:

99%

Product Details

The fully automatic bottle filling capping machine is with CE & ISO 9001 certification.The machine is applied to glass or plastic bottles with different sizes and shapes, and suitable for different filling volume. By adjusting the filling volume on touch screen, it can fill liquid with quick speed and high precision. It is widely used for juice, water, oil, wine, or other liquid filling.

|

Product

|

Liquid Filling Machine Production Line

|

|

Output

|

1500-6000BPH

|

|

Filling Volume

|

2-10ml

|

|

Control

|

PLC and Touch Screen

|

|

Bottle Size

|

Customized

|

|

Cap Feeding

|

Elevator

|

|

Cap Motor

|

Magnetic Motor

|

|

Torquing Range

|

0-100N

|

|

Loading Way

|

Motor Pump Loading

|

|

Capping Type

|

Screw, Pressing, Crimping, etc

|

|

Bottle Type

|

Glass, Plastic, Metal, etc

|

|

Driving Motor

|

Servo Motor

|

|

Power

|

1.8KW

|

|

Voltage

|

220/380V, 50/60Hz

|

|

Machine Frame Material

|

SS304

|

How to arrange the container preciously ?

For cream product , normally we run the unscrambler and round rotary table , they are able to arrange bottle automatically and output to the filler

How to ensure filling speed and precision ?

Servo group scene

Servo group function is mainly for speed , which is more stable and easy adjustment volume

Servo construction

Given the high

viscosity ,can the machine fill it out ?

Filling mixing hopper

There would be a mixing high hopper at the top station of the filler to mix the product while filling , which ensure the good filling stability .

How to control capping ? The good torque

Magnetic motor in torque application

The most important stuff for capping is the torque control ,You will select the torque from 0-100 N on screen , to avoid cap broken or bottle leaking due to torque over or less

Three-jaw capping head

The best point for the capping head is the super high adaptable , it is flexible size which can hold different diameter lids.

Shanghai Xiepai Machinery Equipment Co.,Ltd is a professional manufacturer of filling line for over 12 years, customized filling lines for different industry customers like food and beverage, cosmetic, chemical industry and etc, lots of successful cases for your reference. The full automatic liquid filling machine is designed for saving time on adjusting and testing machine, it can fill liquid or paste accurately by entering a certain filling volume. The PLC control method makes it easy to operate and thigh speed working efficiency is ideal for different scale production. It can work with the automatic capping machine and labeling machine and other equipment based on customer requirement. XIEPAI filling line is widely used in the following industries:

* Beverage Filling Machine Line (such as water, juice, beer, liquor, vodka, wine etc.)

* Food Filling Machine Line (such as honey, sauce, oil, chocolate, vinegar etc. )

* Chemical Filling Machine Line (such as syrup, eye drop, alcohol, reagent, ampoul, syringe etc. )

* Cosmetics Filling Machine Line (such as perfume, body spray, nail polish, cream, lotion, detergent, hand gel etc. )

* Beverage Filling Machine Line (such as water, juice, beer, liquor, vodka, wine etc.)

* Food Filling Machine Line (such as honey, sauce, oil, chocolate, vinegar etc. )

* Chemical Filling Machine Line (such as syrup, eye drop, alcohol, reagent, ampoul, syringe etc. )

* Cosmetics Filling Machine Line (such as perfume, body spray, nail polish, cream, lotion, detergent, hand gel etc. )

A SERIES OF INSTALLATION AND TECHNICAL GUIDE VIDEOS, EASY TO LEARN

Hot Searches