NaN / 0

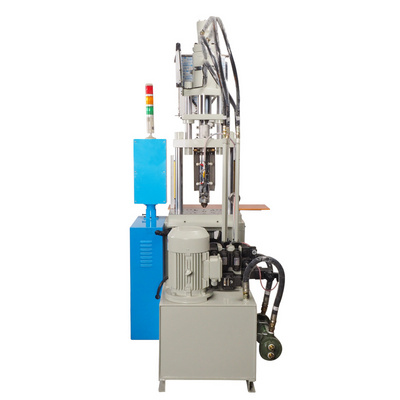

15 ton mini vertical manual plastic patch cord injection molding machine

Get Latest Price

US$ 2900

≥1 Pieces

US$ 2700

≥10 Pieces

Quick Details

Mold Height(mm):

25 - 160

Ejector Stroke(mm):

116 mm

Ejector Force(kN):

12.7 kN

Theoretical Shot Volume(cm³):

71.4 cm³

Product Details

Products Functions

1) Straight screw ejected assembly.

2) Two(three)-phase temperature, ejected speed, backing pressure and screw speed is suitable for various plastic to confectioned.

3) Low-die fixed top active mode makes inserted objects excellent positioned features and the machine has liftout attachment for finished goods.

4) Low-pressure closed die assembly can protect the safety of die.

5) Adopting LCD display.

Product Description

Specification of vertical plastic Injection molding machine:

| MODEL | Unit | JY-160S2 | |

| Screw Diameter | mm | 26 | 28 |

| Max. Shot Weight | gram | 50 | 58 |

| Opening Stroke | mm | 190 | |

| Clamping Force(T) | tons | 15 | |

| Platen Size | mm | 450*280 | |

| Distance Between Tie Bere | mm | 265 | |

| Min Mold Height(KW/HP) | mm | 100/25 | |

| Pum Motor Power | kw/hp | 2.2/3 | |

| Machine Dimensions(LxWxH) | meter | 1.7×1.2×3.0 | |

| Number of Temperature Control | pcs | 3 | |

| Pump Output | L/min | 17.5 | |

| Oil Resservoir Capacity | Liter | 80 | |

| Barrel Heating Power | kw | 1.8 | |

| Cooling Water Consumption | L/hr | 400-600 | |

| Total Power | kw | 4.2 | |

| Machine Weight | tons | 1.8 | |

| Shipping Weight | tons | 0.8 | |

| Screw Barrel Route | mm | 105 | |

Mold Platen Details:

Machine Application

vertical injection machine have the advantage of low noise, low energy consumption,high efficiency and long life time, it's widely apply to produce various terminal blocks, household appliances, consumer electronics, power tools, automotive dashboards, medical devices, open containers, connectors, USB cables,auto parts, Plug ,etc.

Advantages

Packaging & Shipping

1.We will arrabge to manufacture the machine the second day after your confirmation.

2.Before shipment,we will check and test the machine carefully.

3.We will send the machine to your designated place in China.Besides,we can help you send the machine to your seaport if you need.

Hot Searches