NaN / 0

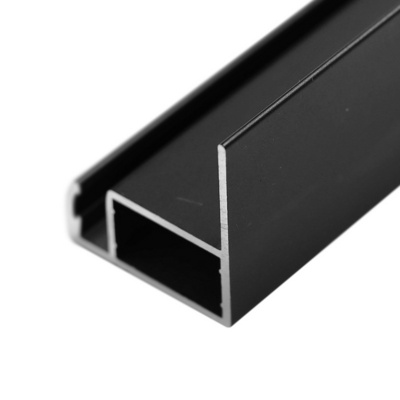

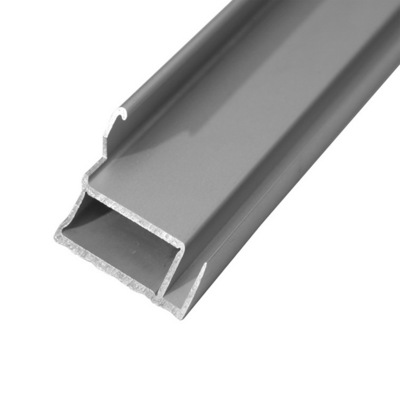

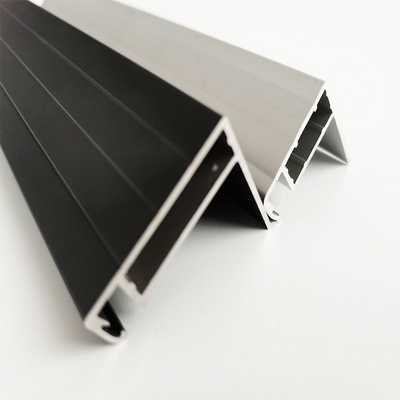

Aluminum Solar Panel Frame Solar Panel Frame Aluminum Profile Mounting Frame

Get Latest Price

US$ 3250

≥10 Tons

US$ 3150

≥20 Tons

Quick Details

Place of Origin:

Anhui, China

Brand Name:

NUUKO

Model Number:

NUKF01

Application:

Solar Panel

Product Details

Product Description

Solar Frame

Aluminum frame is one of the important auxiliary materials of photovoltaic modules. It is used to protect the glass edge, strengthen the sealing performance of photovoltaic modules and improve the overall mechanical strength of photovoltaic modules, which is convenient for the installation and transportation of photovoltaic modules. Photovoltaic module frames are generally made of 6063 or 6005 aluminum profiles, which have the characteristics of light weight, strong corrosion resistance, easy molding, high strength, easy cutting and processing, and recyclability. Currently, the market share of aluminum frames is 96%.

Why choose aluminum profiles for solar frame materials?

The

advantages

of solar frame in photovoltaic applications:

1. Corrosion resistance, strong oxidation resistance;

2. Strong strength and firmness;

3. Strong tensile strength;

4. High elastic modulus, rigidity and metal fatigue value;

5. The transportation and installation are fast, and the appearance will not be oxidized even if it is scratched, and the function will not be affected;

6. After convenient selection of different materials, it can be used to various environments;

7. The service life is more than 30-50 years.

1. Corrosion resistance, strong oxidation resistance;

2. Strong strength and firmness;

3. Strong tensile strength;

4. High elastic modulus, rigidity and metal fatigue value;

5. The transportation and installation are fast, and the appearance will not be oxidized even if it is scratched, and the function will not be affected;

6. After convenient selection of different materials, it can be used to various environments;

7. The service life is more than 30-50 years.

Specification

|

Material

|

6000 serious,alloy 6063/6061/6005

|

|

Surface Finish

|

Powder Coating, Anodizing, Brushing, Polishing, Electric-plating, powder Coating, Hot Dip Galvanizing, E-coating, Tin Plating, Nickel Plating, Chrome Plating, Decorate, Enamel Coating and etc.

|

|

Processing

|

Anodized, Powder Coated, Sandblasting, Electrophoresis, Titanium Powder Coating, Polish, Brushed, PVDF coating, Wood-grain etc.

|

|

More Processing

|

CNC Machining, Plastic Injection, Stamping, Die Casting, Welding, Forging, Silicone and Rubber, Mould Making, etc

|

|

Annealing

|

T3-T8

|

|

Application

|

Solar Panel Frame, Solar Panel System Mount

|

|

Normal Anodizing thickness

|

≥8μm

|

|

Normal powder coating thickness

|

60-120μm

|

|

Tensile strength

|

≥160mpa

|

|

Yield strength

|

≥110mpa

|

|

Extensibility

|

≥8%

|

|

Hardness(HW)

|

8-15

|

|

Test

|

100% QC testing

|

|

Temper

|

T5/T6

|

|

Shape

|

Square, Round, Flat, according to customers' drawings

|

|

Color

|

Silvery White, Black, Golden, Champagne, Dark Bronze or according to your requirement

|

|

Surface Treatment

|

Anodize/Sandblasting/Powder Coating

|

Packing & Delivery

Hot Searches