NaN / 0

Sublimation paper for mugs A4 heat transfer paper for T Shirts Textile

Get Latest Price

US$ 3

≥100 Pieces

US$ 2.8

≥1000 Pieces

US$ 2.5

≥5000 Pieces

Quick Details

Material:

White Paper

Application:

Clothing

Type:

Sublimation Transfer

Place of Origin:

Guangdong, China

Product Details

Sublimation paper for mugs A4 heat transfer paper for garment

information of sublimation paper

use on polyester. glass.ceramic.MDF. plastic.metal.stone. ect

A4 size :21*29.7cm

Product Description

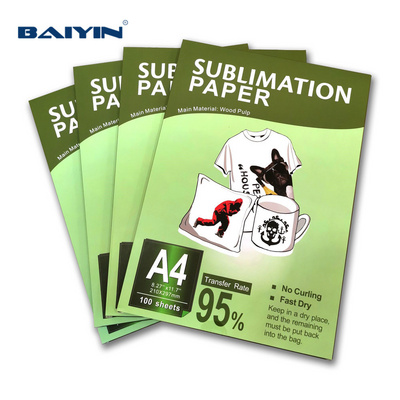

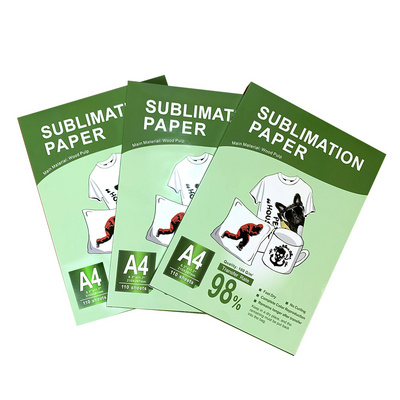

Specification

Size: A4, 8.3x 11.7 inches / 210x 297 mm

Quantity: 100 Sheets

GW weight: 13KGS (20 packs)

Transfer Rate: 98%

Feature

Fast Dry, No Curling, No Fade, No Crack, Wide Range of Applications, IPX-2 Waterproof, High Transfer Rate, Complete Color Reproduction, the Pattern remains longer after transfer.

Please keep in a dry place, put the unused paper back in the box. If it is placed outside the box for a long time, the paper will absorb the moisture in the air and become curly and metamorphic.

Applications

Textile Fabrics: Light / White Polyester T-shirt, Modal clothing, Flax pillow, Oxford fabric bag, Mouse pad, etc. Sublimation paper can ’ t use on pure cotton t-shirts.

Hard items: Ceramic mug , Glass beer cup , Metal sports bottle, plate , High temperature phone case , Stone Slates, MDF & Wood Blanks, Tile, Key chain, M etal s heet , etc. If the transfer effect is poor, please check whether there is sublimation coating on the hard surface.

Process for My T-shirt

Step 1. Printed on the white surface of sublimation paper, Select "Mirror Mode" in the software (such as PS, CDR).

Step 2. Set the temperature and time on the heat press machine, Press the clothes for 3 seconds after reaching the temperature. After flattening, the clothes can be better transferred.

Step 3. Make sure the paper's place, Start the machine to start transferring the pattern, Get the perfect artwork! Find the best temperature and time for substrate, Please use the waste cloth for practice first.

Temperature and Time

|

Material |

Temp |

Time (s) |

Increase time E ach time |

Attention |

|

Light/ White

|

360 ℉ 180 ℃ |

20 |

5 |

The color of the sublimation paper looks dark after printing. this is normal,

y

ou can get the real color after transfer.

|

|

Metal Board |

20 |

|||

|

Ceramic mug |

170 |

|||

|

Ceramic plate |

180 |

|||

|

MDF & Wood Blanks

|

30 |

|||

|

MDF & Wood Blanks

|

150 |

10 |

||

|

Glass beer cup |

150 |

10 |

||

|

Stone Slates

|

240 |

30 |

||

|

Aluminum Bottle |

340 ℉ 170 ℃ |

25 |

5 |

|

|

Stainless Steel Bottle |

30 |

|||

|

Mouse Pad |

375 ℉ 190 ℃ |

30 |

Common Question

Q: Can I use my normal Ink?

A: No, If you use normal ink, it can print, but it can’t transfer! Sublimation paper can only be printed with sublimation ink, and then carry out the transfer work.

Q: How do I choose a printer?

A: Sublimation paper is suitable for all Inkjet Printers (For Epson, HP, Canon, etc). Due to the large particle size of sublimation inks, when your inkjet printer uses sublimation ink, it will not work with normal ink. Therefore this inkjet printer can only use sublimation ink.

Q: Why does the color look less colorful after the sublimation paper is printed?

A: This is normal. Since the coating of the sublimation paper has a good absorption effect, the display color is relatively dull, so that a more complete color can be transferred. Please continue to complete the transfer and see the true color effect on the substrate.

Q: I tried many times according to the operation manual. The finished product effect is still not ideal in the end. What should I do?

A: Due to the large number of equipment involved in the work, please check each of the following items

1:Whether the substrate is wet/ expired/ poor quality, the surface of the hard object must have a sublimation coating.

2:Printer Settings: Set the paper to “High Quality Plain Paper/Photo Paper”, set the quality to “High Quality” and set the speed to “Slowest”. Click "More Options" to customize the color correction.

3:Whether the sublimation ink has expired/ deteriorated. Notice: Do Not Use Oily Ink.

4:Heat press machine heating plate is not enough heating / Large temperature fluctuation / time is not enough. If 360℉ / 180℃ is set, please use a thermometer to test at multiple positions on the heating plate . It is normal for the heating plate to reach 340℉ / 170℃ .

5:Whether the sublimation paper packaging is damaged/wet and curled.

6:You can use Teflon sheet to cover the substrate to help maintain temperature.

Each step above affects the final product. Please try it out and test it several times to get the perfect masterpiece.

If you have any questions, please feel free to contact us and we provide free technical support for life .

If you are satisfied with our products and services, please feel free to purchase again, and leave your artwork in REVIEW . It's an encouragement to us and a affirmation to our products , this ’ s very important to us, thank you for your order and reading!

Product Specs

Contact us

Hot Searches