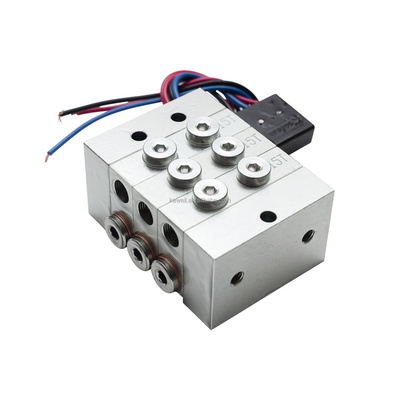

Progressive Lubrication

It is the most reliable and comprehensive system offered by us to measure grease and oil with actual control on operation. The 3 types of progressive metering can be combined with automatic or manual pumps or powered directly from a single point in the system. Suitable for industrial machinery and the vehicle sector.

Volumetric lubrication

It is the most reliable and comprehensive system offered by us to measure grease and oil with actual control on operation. The 3 types of progressive metering can be combined with automatic or manual pumps or powered directly from a single point in the system. Suitable for industrial machinery and the vehicle sector.

Volumetric lubrication

Consisting of manual or automatic pumps combined with volumetric metering valves, the volumetric lubrication system can measure oil or grease. Normally installed in industrial machinery, it also allows for lubrication in systems with several points. You can control pump operation and circuit integrity.

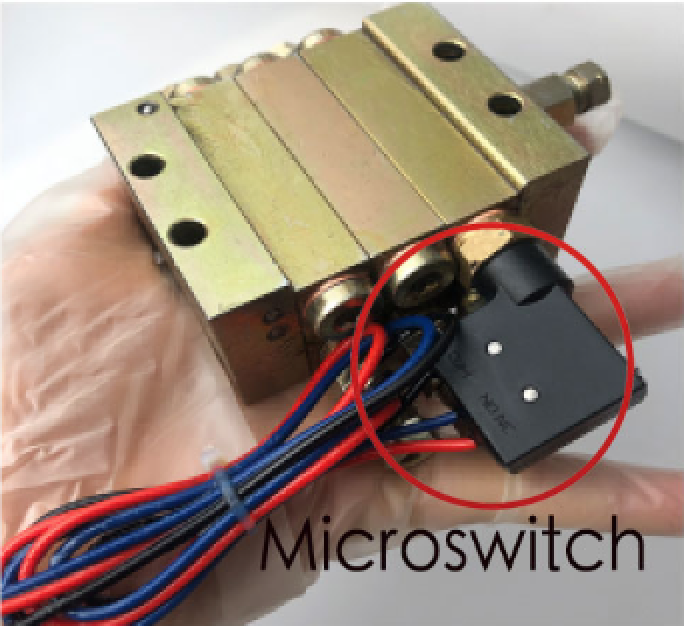

Resistive Lubrication

It is the basic system that can dispense only oil and combined with manual or automatic pumps, resistive metering units allow for continuous or intermittent lubrication depending on the metering and type of supply. Particularly suitable for agricultural overhead contact lines and small systems.

Main products : Automatic lubrication pump, electric lubrication pump, pneumatic lubrication pump, manual lubrication pump, grease pump, progressive distributor, quantitative distributor, pipe connector, metering unit, high pressure nylon hose, high pressure pipe etc.

These products are widely used in robot, cutting machine tools, forging machine, plastic machine, CNC machine tools, construction machinery, vehicles, metallurgical machinery, textile machinery, printing machinery, woodworking machinery, chemical machinery, mining machinery and other industrial machinery.

Our customer : We mainly exported to Russia ,Brazil ,Australia, Thailand,South korea and so on.

Our team : If you interesting in our lubrication products , please let us know. We will be pleased to give you a quotation according your detailed specifications in short time . If you have technical help ,Our expert engineering team also will ready to serve you for consultation and feedback . We can provide you professional technical info about products in time.

Products control : Each product is carefully made with strictly controller and testing , it will make you satisfied. We trust that only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation.

Our attitude : In order to build long-term friendly relationship. We all significantly promise: same excellent, better selling price; exact selling price, better quality.

If you have any question, do not hesitate to contact us.

Resistive Lubrication

It is the basic system that can dispense only oil and combined with manual or automatic pumps, resistive metering units allow for continuous or intermittent lubrication depending on the metering and type of supply. Particularly suitable for agricultural overhead contact lines and small systems.

Main products : Automatic lubrication pump, electric lubrication pump, pneumatic lubrication pump, manual lubrication pump, grease pump, progressive distributor, quantitative distributor, pipe connector, metering unit, high pressure nylon hose, high pressure pipe etc.

These products are widely used in robot, cutting machine tools, forging machine, plastic machine, CNC machine tools, construction machinery, vehicles, metallurgical machinery, textile machinery, printing machinery, woodworking machinery, chemical machinery, mining machinery and other industrial machinery.

Our customer : We mainly exported to Russia ,Brazil ,Australia, Thailand,South korea and so on.

Our team : If you interesting in our lubrication products , please let us know. We will be pleased to give you a quotation according your detailed specifications in short time . If you have technical help ,Our expert engineering team also will ready to serve you for consultation and feedback . We can provide you professional technical info about products in time.

Products control : Each product is carefully made with strictly controller and testing , it will make you satisfied. We trust that only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation.

Our attitude : In order to build long-term friendly relationship. We all significantly promise: same excellent, better selling price; exact selling price, better quality.

If you have any question, do not hesitate to contact us.