NaN / 0

Automatic green onion rings julienne peeling and root cutting machine

Get Latest Price

US$ 585

≥1 Sets

US$ 550

≥5 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

Ainuok

Type:

Multi-function vegetable cutter

Weight:

75 KG

Product Details

Automatic green onion rings julienne peeling and root cutting machine

Product Description

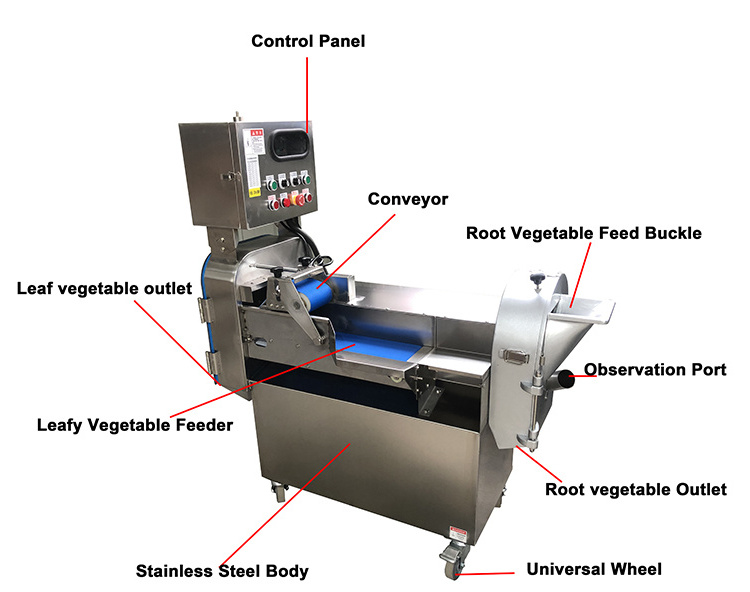

1. The Vegetable cutters are mainly used for the processing of rooting and leafy vegetables and fruits . It can slice , shred , strip , and dice the ingredients, all thicknesses can be adjusted by cutters and the belt conveyor’s speed. Concerned the food safety, we design it to be easy to install , remove , operate , and clean . It is divided into multi-function vegetable cutter, root vegetable cutter, leaf vegetable cutter.

2. According to the customer's output requirements and raw materials, we have 4 types for option .

Application

Equipment Advantage

1. All stainless steel body , the whole machine waterproof Stainless steel body, not easy to rust, bring its own wheel, easy to move , stylish and beautiful, durable! Lightweight. Strong. Durable Multi-functional two-headed chopping machine

2.Integrated control board design , high yield The whole panel uses high-tech computer design, easy to operate , easy to get started! Easy to operate Multi-functional two-headed chopping machine The use of multi-functional integrated control panel, the entire panel is simple and clear, well-designed, according to different needs at any time to adjust the supply speed, thus ensuring efficiency and yield, fast start!

3.High-quality conveyor belt ,The conveyor belt is made of rubber, with high friction strength, long-lasting wear, and a beautiful appearance! Long service life, removable cleaning, no dead end hygiene!

4.High-strengh steel disc Knife plate using stainless steel material, safe and hygienic wear, long service life , to provide you with customized services!

Detailed Images

Send Inquiry Now

Click

Send Inquiry

or

Send

below,

Write your requirements down,

Latest

Catalogue with Full Prices

will be sent right now.

Specification

|

Type |

AK Q-20 |

AK Q-180 |

AK Q-266 |

AK Q-288 |

|

Root Vegetable Cutting Motor(kw) |

/ |

1.5 |

1.5 |

1.5 |

|

Leaf vegetable cutting motor (kw) |

0. 18 |

/ |

1.1 |

1.1 |

|

Belt width ( mm ) |

80 |

/ |

80 |

120 |

|

Leaf Vegetable Cut Sizes ( mm ) |

1-20 |

/ |

1-20 |

1-60 |

|

Slice Sizes ( mm ) |

/ |

2-10 |

2-10 |

2-10 |

|

Shred Size ( mm ) |

/ |

2-10 |

2-10 |

2-10 |

|

Diced Size ( mm ) |

/ |

6 , 8 , 10 , 12 , 15 , 20 |

6 , 8 , 10 , 12 , 15 , 20 |

6 , 8 , 10 , 12 , 15 , 20 |

|

Output (kg/h) |

120-350 |

300-500 |

120-1000 |

600-1000 |

|

Size(m) |

0.75 *0. 65 * 0.85 |

0.9 *0. 65 *1. 1 |

1 * 0.8 *1. 15 |

1.3*0.8*1.5 |

|

Weight (kg) |

75 |

115 |

155 |

175 |

Tips:For more details,please contact us

Packaging & Shipping

1. 5 layers of plastic film wrapped around the body to prevent moisture and rain during transportation.

2. Export thick wooden box, 5-15 cm thick, to ensure the safety of the machine during transportation.

3. Trucks and centralized boxes directly transport the machines from the factory to the port for loading.

Hot Searches