NaN / 0

Aluminum Composite Panels dibond panel printing

Get Latest Price

US$ 9.99

≥300 Square meters

US$ 9.89

≥3000 Square meters

US$ 9.59

≥10000 Square meters

Quick Details

Warranty:

More than 5 years

Size:

1220*2440mm, 4X8ft

Project Solution Capability:

total solution for projects

Application:

Outdoor

Product Details

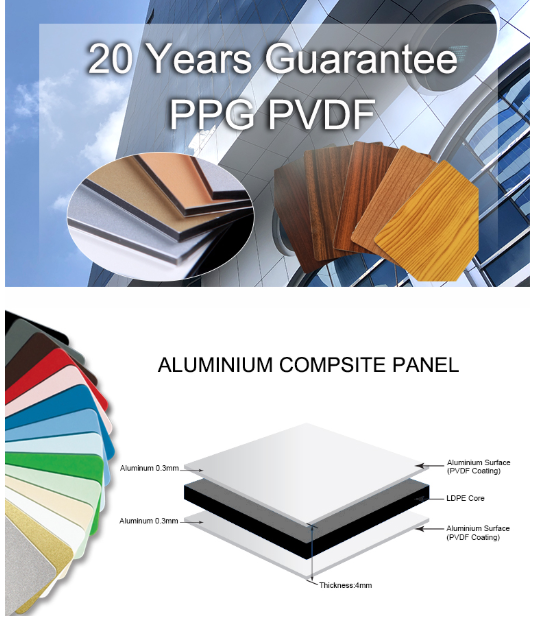

2mm 3mm 4mm 5mm 6mm PE and PVDF Coated Alucobond Aluminum Composite Panels

PE/PVDF Coated ACP Constitution Structure:

1) Protective film with IDEABOND/OEM brand or as requested.

2) Front side: aluminum roll coated with PE/PVDF

3) Macromolecular lamination film.

4) Core: Non-toxic polyethylene.

5) Macromolecular lamination film.

6) Rear side: Aluminum coated with primer or as requested.

aluminium composite panel sheet manufacturers

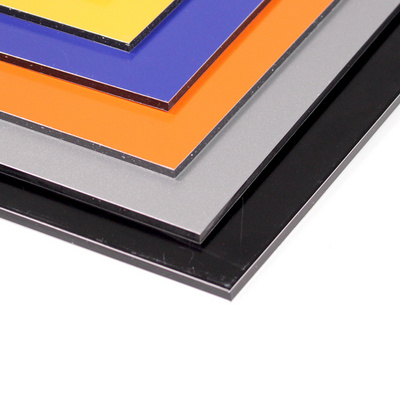

Aluminium composite panel consisting of two aluminium cover sheets(AA1100 Series or AA3003 Series) sandwiching a non-toxic low density polyethylene core produced from a continuous extrusion process.Used for cladding,advertising.It’s usually called Aluminium composite panel,shortened as ACP or ACM.

1) Protective film with IDEABOND/OEM brand or as requested.

2) Front side: aluminum roll coated with PE/PVDF

3) Macromolecular lamination film.

4) Core: Non-toxic polyethylene.

5) Macromolecular lamination film.

6) Rear side: Aluminum coated with primer or as requested.

aluminium composite panel sheet manufacturers

Aluminium composite panel consisting of two aluminium cover sheets(AA1100 Series or AA3003 Series) sandwiching a non-toxic low density polyethylene core produced from a continuous extrusion process.Used for cladding,advertising.It’s usually called Aluminium composite panel,shortened as ACP or ACM.

Products Description

Aluminium Composite Panel Quick Details

2)Dimensions:

A) Thickness: 3mm,4mm,6mm,8mm,10mm.

B) Width: 1220mm,1250mm,1500mm,1570mm,1800mm,2000mm(max).

C) Length: 2440mm,3050mm,3200mm( max:6000mm).

D) Weight: 5.5kg/sqm baesd on 0.5/4mm thickness.

E) Standard size:1220*2440mm.

F) Qty/20'fcl:4mm/2380sqm; 3mm/2977sqm.

G) Non-stanard size are available according to requirement.

3)Standard:

A) West Europe standard ( Germany DIN Standard).

B) The EAST Europe standard ( Russian standard ).

C) The commonweathlth standard (U.K BS Standard ).

D) The North America ASTM standard.

ACP compared with different products( Lightness / Rigidity ):

The composite structure of Alumtimes® results in an impressive strength-to-weight ratio, even when comparing large panel sizes. Despite its low weight, which makes Trubond easy to transport and handle in the factory and on site, its rigidity and high strength make the panels keep their shape and remain flat, even when exposed to extreme temperature changes. Comparison of thickness and weight of panels with equal rigidity.

Trubond ACP compared with solid aluminium:

Required thickness and actual weights of panels with same rigidity

|

Trubond ACP

|

|

Aluminum

|

|

|

|

||||

|

Rigidity (E J)

|

Section modulus

|

Thickness

|

Weight

|

Thickness

|

Weight

|

||||

|

1250 kN cm2/m

|

1.25 cm3/m

|

3 mm

|

4.5kg/m2

|

2.7 mm

|

7.3kg/m2

|

||||

|

2400 kN cm2/m

|

1.75 cm3/m

|

4mm

|

5.5kg/m2

|

3.3 mm

|

8.9kg/m2

|

||||

Trubond ACP Physical Properties for Panel:

|

Panel density

|

5.5kg/m2

|

|

Aluminium Skin Thickness

|

Average 7.0 N/mm

|

|

Tensile Strength

|

52.5 Mpa

|

|

Flexural Strength

|

100.0 Mpa

|

|

Shear Strength

|

28.1 Mpa

|

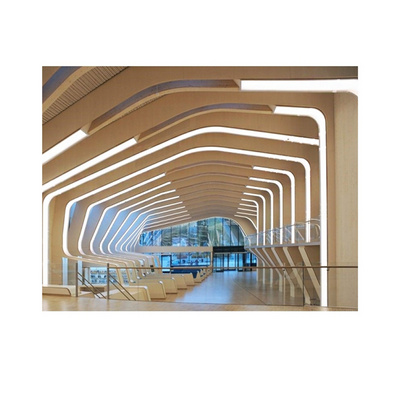

Application Scope

1)Building exterior curtain walls

2)Decoration reformation storey-addition for old buildings

3)Decoration of interior walls,ceilings,bathrooms,kitchens and balconies

4)Shop’s door decoration

5)Advertisement boards,display platforms and signboards

6)Wallboards and ceilings for tunnel

7)Industrial material , vehicle and boat materials

Hot Searches