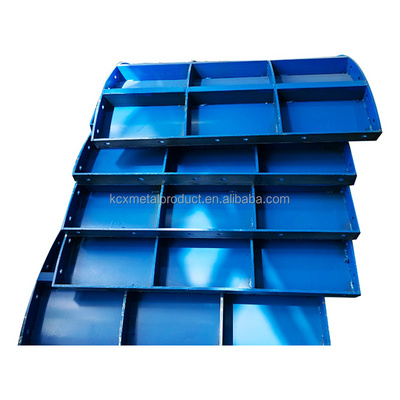

2. Experienced in the box beam design and Manufacturing for over

20

years.

3. Strict Quality Control System: ISO QMS qualified with certifications.

4. Effective Safety Production Management: the safety factory is about 1.2 times than the industry standard.

5. Selective Raw Material, High Cutting accuracy and Excellent welding consistency, high reusable rate .

3. Strict Quality Control System: ISO QMS qualified with certifications.

4. Effective Safety Production Management: the safety factory is about 1.2 times than the industry standard.

5. Selective Raw Material, High Cutting accuracy and Excellent welding consistency, high reusable rate .

6. Nice assembly precision with perfect structural stability.

Longer lifespan

.