NaN / 0

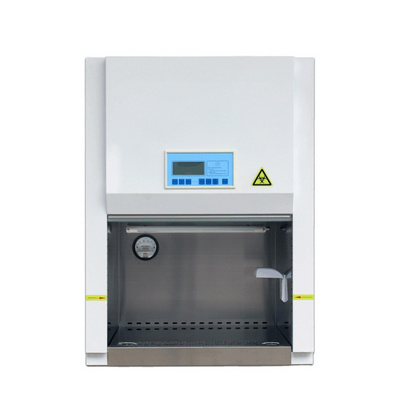

Bio safety cabinet biosafety cabinet class 1

Get Latest Price

US$ 6000

≥2 Sets

Quick Details

Application:

Hospital, School, Other, Cleanroom, Electronics, Opto-electronics, Semi-conductor, Labratory

Design Style:

Traditional

Material:

Metal

Place of Origin:

Taiwan, China

Product Details

Biological Safety Cabinet (BSC)

Details Images

Products Description

◉ This is a completely closed cabinet, isolate operating personnel or objects to

avoid damage by harmful substances, protective role.

◉ It is often used in high-polluting, high toxicity, high hazard job.

◉ Exposure to toxic chemical biology, food testing, pharmaceutical and health

◉ It is often used in high-polluting, high toxicity, high hazard job.

◉ Exposure to toxic chemical biology, food testing, pharmaceutical and health

hazardous industries ideal for devices.

◉ Customized size and specification are available to meet customer's requirements.

◉ Customized size and specification are available to meet customer's requirements.

|

Selection of Biological Safety Cabinet (BSC)

|

|

|

||

|

Catagory

|

Laboratory Type

|

Type of Protection

|

||

|

Class I

|

Group 1-3, microorganisms in Risk;

Slightly volatile, radionuclide/chemical protection

|

Operator, Environment

|

||

|

Class II A1

|

Group 1-3, microorganisms in Risk

|

Operator, Environment, Product

|

||

|

Class II A2

|

Group 1-3, microorganisms in Risk

|

Operator, Environment, Product

|

||

|

Class II B1

|

Group 1-3, microorganisms in Risk;

Slightly volatile, radionuclide/chemical protection

|

Operator, Environment, Product

|

||

|

Class II B2

|

Group 1-3, microorganisms in Risk;

Minute amounts volatile, radionuclide/chemical protection

|

Operator, Environment, Product

|

||

|

Class III

|

Group 1-3, microorganisms in Risk;

Volatile, radionuclide/chemical protection

|

Operator, Environment, Product

|

||

Class I BSC

◉ Feature: Designed primarily for the protection of the operating personnel

◉ Application: It is used for laboratories which are work with nonvolatile, radionuclide/checmial protection, microorganisms in risk.

◉ Exhaust System: External (hard duct)

◉ Exhaust System: External (hard duct)

|

BSC Grades

|

Inlet Air Velocity

|

% of Airflow

|

|

|

|

|||

|

|

m/s

|

Internal Recirculation

|

Exhausted

|

|

|

|||

|

Class I

|

0.38

|

0

|

100

|

|

|

|||

Class II BSC

◉ Feature: Designed not only to provide personnel protection but also to protect work surface materials from being contaminated by the room air which is drawn into the cabinet. And it is used for protecting the laboratory environment as well. It is acceptable for working with medium-level risk tests. And according to the National Sanitation Foundation Standard, NSF/ANSI 49(2002), it can be defined and classified as 4 types. Their features are compared as below.

◉ Application: It is used for laboratories which are work with nonvolatile, radionuclide/checmial protection, microorganisms in risk.

◉ Exhaust System: Class II A1 & A2 - Internal or external (exhaust hood); Class II B1 & B2 - External (hard duct)

◉ Exhaust System: Class II A1 & A2 - Internal or external (exhaust hood); Class II B1 & B2 - External (hard duct)

|

BSC Grades

|

Inlet Air Velocity

|

% of Airflow

|

|

|

|

|||

|

|

m/s

|

Internal Recirculation

|

Exhausted

|

|

|

|||

|

Class II A1

|

0.38

|

70

|

30

|

|

|

|||

|

Class II A2

|

0.5

|

70

|

30

|

|

|

|||

|

Class II B1

|

0.5

|

30

|

70

|

|

|

|||

|

Class II B2

|

0.5

|

0

|

100

|

|

|

|||

Class III BSC

Feature: Suitable for work in Bio-safety Level 3 and 4 laboratories and provide the protection for the highest hazardous level of the Risk Group 3, Risk Group 4, or above. It virtually is a sealed gas tight cabinet. Moreover, its supply air is HEPA- filtered and exhaust air passes through two HEPA filters which keep the cabinet interior under negative pressure consequently. The only way of accessing to the work surface for operation is by means of heavy duty rubber gloves, which are attached to ports in the cabinet virtually.

◉ Application: It is used for laboratories which are work with lightly volatile, toxic, radionuclide protection, microorganisms in risk.

◉ Exhaust System: Exhaust air should pass through two filters.

◉ Exhaust System: Exhaust air should pass through two filters.

|

BSC Grades

|

Inlet Air Velocity

|

% of Airflow

|

|

|

|

|||

|

|

m/s

|

Internal Recirculation

|

Exhausted

|

|

|

|||

|

Class III

|

N/A

|

0

|

100

|

|

|

|||

Our Products

Certificate

Manufacturing license of the medical devices

License No. QMS2094

In order to get the manufacturing license, our company has passed the inspection against the Medical Device Quality Management

System Regulations.

QMS, Quality Management System also known as GMP.

It is to ensure our device is able to be consistently produced and controlled by the proper quality standards.

We are the only Taiwan company in our industry to pass the QMS inspection.

In order to get the manufacturing license, our company has passed the inspection against the Medical Device Quality Management

System Regulations.

QMS, Quality Management System also known as GMP.

It is to ensure our device is able to be consistently produced and controlled by the proper quality standards.

We are the only Taiwan company in our industry to pass the QMS inspection.

ISO 13485: 2016

ISO 13485 is an international standard that specifies requirements for quality management systems for manufacturers.

The purpose is to ensure the we can provide high standards of quality assurance and product safety for our products and services,

increase consumer trust and loyalty, and enhance corporate image and market competitiveness.

Less than 1% of Taiwan companies in our industry register.

The purpose is to ensure the we can provide high standards of quality assurance and product safety for our products and services,

increase consumer trust and loyalty, and enhance corporate image and market competitiveness.

Less than 1% of Taiwan companies in our industry register.

ISO 9001: 2015

ISO 9001 is an international standard that specifies requirements for quality management system.

This standard helps us to provide products and services with consistent quality.

This standard helps us to provide products and services with consistent quality.

ISO 14001: 2015

ISO 14001 is an international standard that focuses on how businesses and organizations manage their environmental impacts.

The standard provides a framework for establishing an effective Environmental Management System (EMS) to help us achieving

environmental objectives and reduce the impact on the environment.

The standard provides a framework for establishing an effective Environmental Management System (EMS) to help us achieving

environmental objectives and reduce the impact on the environment.

UL 507

UL 507 is a standard issued by Underwriters Laboratories for electric fans and electric fan accessories.

Our FFU is a critical product widely used in cleanroom environments, such as medical, semiconductor, and other high-purity

applications.

By achieving this certification, our FFU proves that it meets the strictest safety and performance requirements, providing

customers with higher quality and more reliable products.

Our customers can confidently use our product, knowing that it meets the highest safety and performance standards.

Our FFU is a critical product widely used in cleanroom environments, such as medical, semiconductor, and other high-purity

applications.

By achieving this certification, our FFU proves that it meets the strictest safety and performance requirements, providing

customers with higher quality and more reliable products.

Our customers can confidently use our product, knowing that it meets the highest safety and performance standards.

SEMI

The SEMI Standard is

internationally used in

aspects of

semiconductor, photovoltaic (PV), LED, MEMS, and flat panel display (FPD)

manufacturing

industries

. By achieving this standard, it ensures our

reliability and productivity.

SEMI S8 - Safety Guideline for Ergonomics Engineering of Semiconductor Manufacturing Equipment

SEMI S22 - Safety Guideline for the Electrical Design of Semiconductor Manufacturing Equipment

Packaging & Shipping

Our goods are packed with standard export packing methods and the goods are well protected.