NaN / 0

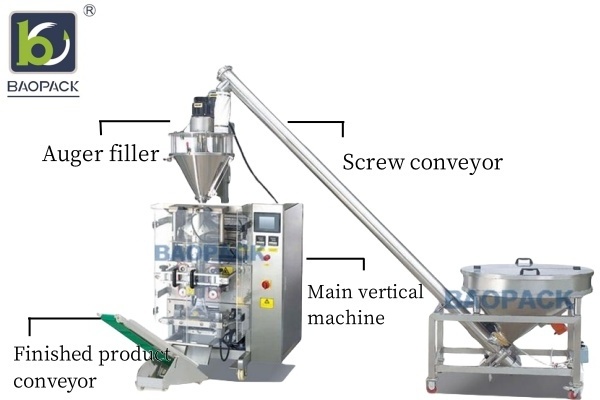

1kg 2kg 5kg flour detergent washing powder bag making fully automatic packaging machine

Get Latest Price

US$ 10500

≥1 Sets

Quick Details

Function:

FILLING, Labeling, Sealing

Packaging Type:

Stand-up Pouch, Bags, Pouch

Packaging Material:

Plastic, Paper

Production Capacity:

150bag/min

Product Details

Powder packaging machine

BAOPACK Factory 26 years introduction:

https://baopacking.en.alibaba.com/?spm=a2700.7756200.0.0.248f71d2U48jZL

|

Item |

CB-VG42 |

CB-VG52 |

|

Capacity |

150 bags/min |

150 bags/min |

|

Bag size |

(L)50-300mm (W)50-200mm |

(L)50-3 5 0mm (W)50-2 5 0mm |

|

Max film width |

420mm |

520mm |

|

Film thickness |

0.04-0.09mm |

0.04-0.09 |

|

Pulling belt type |

Continuous pulling film |

Continuous pulling film |

|

Air consumption |

0.8Mpa 0.3m3/min |

0.8Mpa 0.3m3/min |

|

Total power |

4KW |

5.6 KW |

|

Voltage |

Four wire three phase 380V 50 /60 HZ |

Four wire three phase 380V 50 /60 HZ |

|

Dimension |

L1736*W1081*H1452mm |

L17 40 *W 1180 *H 1700 mm |

|

Weight |

700kg |

800kg |

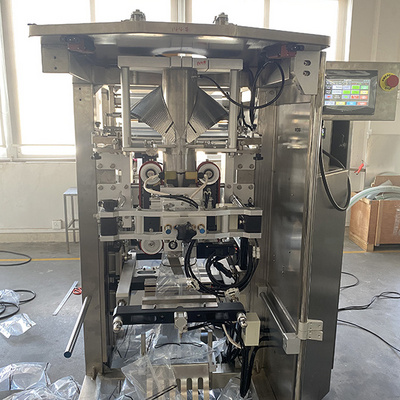

| Product Display |

SAMPLE

Advantage

| CB-VG52 |

FEATURES:

1. China’s first & only high speed packaging machine, up to 150 bags/min

2. VG42 was awarded design patent

3. Continuous filling and sealing by 4 servo motors, work stable, very low maintenance

4. All the electric parts are the world famous brand

5. Over 90% spare parts are high quality stainless steel

6. Film drawing system by the BECKER vacuum pump, faster and more stable

7. Minimalist film frame design, easy to adjust the eye mark and installation

| Detailed Description |

|

FILM PULLING The pull film belt is controled by double sevro motor,each motor control each film ,so the pull film system is more stable and accurate.The pull film belt with holes ,these holes are connected to the vacuum pump,the suction is strong which can pull the film more stable. |

|

|

Vacuum pump

Vaccum pulling film, it could make pulling belt more long life and customer no need to always change fulling belt film and save time and cost for customer. |

|

|

LARGER TOUCH SCREEN

In the new design,when you debug machine,you can adjust the screen to fit you.Big color touch screen and can save 8 groups of parameters for different packing specification.

|

|

|

4 Servo motors 1. Servo motor could be Siemens and Schinder brand for customer option. 2. Pulling film be controlled by double servo motor. One servo motor control horizontal sealing parts and antoher one control longitudinal. 3.Longitudinal parts with steel band, so that it could match high speed system, make more beautiful longitudinal sealing and well gas tightness.

|

| Product Information |

| Hot Sales |

Company Overview

| Company Overview |

|

* BAOPACK Auto Packaging Machine Co., Ltd.is located in Foshan City, Guangdong province, southern China, owning more than 10000m2 standard modernized workshop with high technology. Since 1994 , company founder Zhou Guanglin, engaged in packaging machinery industry. BAOPACK’s mission is to keep developing intelligent vertical packaging machines and offer full automatic packaging solutions.

* In BAOPACK, we have professional R&D, production, technical support, sales and after- sales service team. Till now, over 10,000 series packaging lines are running in more than 100 countries from us. BAOPACK is your best choice! We are always trying to maximize your return on investment!

* With more than 20-year experience in packaging machine industry , BAOPACK has become major driving force for this filed in China by technology innovation, and talent developing.

* In order to promote the enterprise internal management to be more scientific and standard, we have successfully passed the ISO9001:2000 . It provides a sufficient guarantee for our product quality control & service developing.

* In order to make the product export successfully to EU, we have passed CE safety certification . High quality products& perfect service make us obtain a high reputation in the industry and among customers!

* With high quality and advanced technology, BAOPACK developed more than 30 series of packaging machines which have been widely used and meet the needs of many customers in many fields, such as in the fields of puffed food, snacks, deep frozen food, agricultural industry, pharmaceutics, chemical industry, hardware, ect. We cooperate with manufactures for snack food and food fry industry to provide customers one-step service. We established office in Hunan, Jinan, Chengdu, Jiangsu, Shenyang and other cities. |

| For more product information , please click | CONTACT US > |

| Exhibition |

| BACK TO HOMEPAGE > |

Hot Searches