NaN / 0

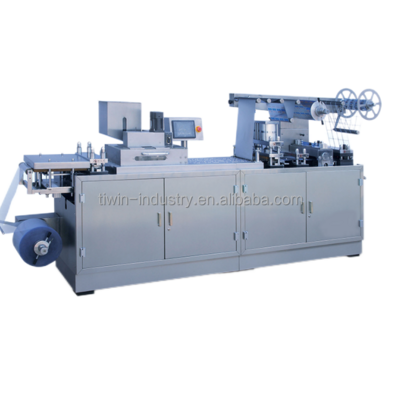

Micro sd memory card flat-plate automatic blister packing machine paper and cardboard packing machine price

Get Latest Price

US$ 1290

≥1 Sets

US$ 990

≥5 Sets

US$ 890

≥10 Sets

US$ 690

≥20 Sets

Quick Details

Function:

Wrapping, Labeling, Sealing

Packaging Type:

Bags

Packaging Material:

Paper

Weight (KG):

269

Product Details

Micro sd memory card flat-plate automatic blister packing machine paper and cardboard packing machine price

Micro sd memory card flat-plate automatic blister packing machine paper and cardboard packing machine price

Product Description

Introduction of toothbrush package machine/toothbrush blister packing machine :

Blister sealing machine is mainly used for heat sealing packaging blister blister and paper card.using the pulse heating principle (36 v voltage causes bakelite mold heat) according to the workpiece size (thermal bonding area) choose different output current and the polarization time, then cooling pressure to complete a thermal packaging.Beautiful transparent packaging products, packaging speed.Mainly used: packaging,Stationery, daily necessities, cosmetics, Small tools etc.

Features of toothbrush package machine/toothbrush blister packing machine :

1.Easy to operate our PE blister sealing machine: only need choose the prolong time, heating time, cool- down time and transform the grade of heating current, spin the working plate with hand, then the prolong time system, heating system and cool system will be automatically operate, finish all the sealing process.

2.This working plate has three working position, with speedy packing and high efficiency.

3.Mould only suit for local sealing of the edge of blister and card, do not affect the packing, the blister and card can be clean and beautiful.

4.Machine body structure is strong, reliable and durable.

Application of toothbrush package machine|toothbrush blister packing machine :

1. Synchronously weld and cut of cardboard plastics cover(like toothbrush packing)

2. Synchronously weld and cut of leather product: Auto leather chair, shadow shield, shoes, footwear products, watch band, CD bag, trademark etc.

3. Welding and cutting PET, APET, PETG, PP, PVC, EVA and other environment friendly material at one times.

4. Polyester materials welding and cutting.

5. Car seat polyester or leather materials, sun shield and handles welding.

6. Coth coated materials welding and cutting.

Technical parameters of toothbrush package machine|toothbrush blister packing machine :

|

Model |

MN 8000 |

|

High frequency output |

8K W |

|

Voltage |

380V( 50HZ ) |

|

Time limit |

1S----99S |

|

Input power |

15KVA |

|

Oscillation frequency |

40.68MHz |

|

Upper and lower electrode spacing |

250mm |

|

Temperature Controller |

30-300℃ |

|

Weight |

816KG |

|

Dimension |

1400X 700X2000mm |

Final production :

Trade Assurance List

Hot Searches