After the work hardening, the initial hardness can thereby reach upto approx. 50 HRC. The deeper-set, not yet hardened layers thereby provide for the great toughness of this steel. The depth and hardness of the work-hardened surfaces depend on the application and type of manganese steel.

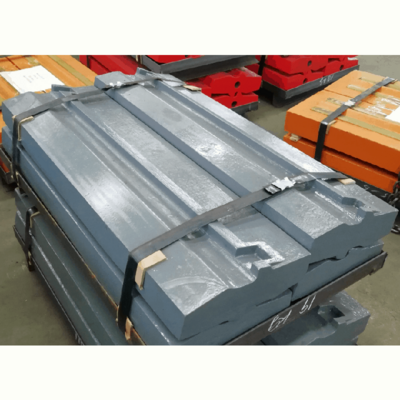

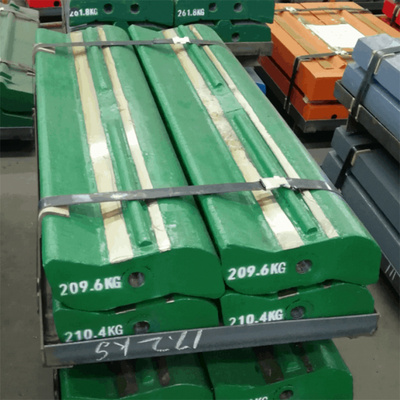

Manganese steel has a long history. Today, this steel is used mostly for crusher jaws, crushing cones and crushing shells (mantles & bowl liners). In the impact crusher, it is only recommended to use manganese blow bars when crushing less abrasive and very large feed material (e.g. limestone).

CHROME STEEL

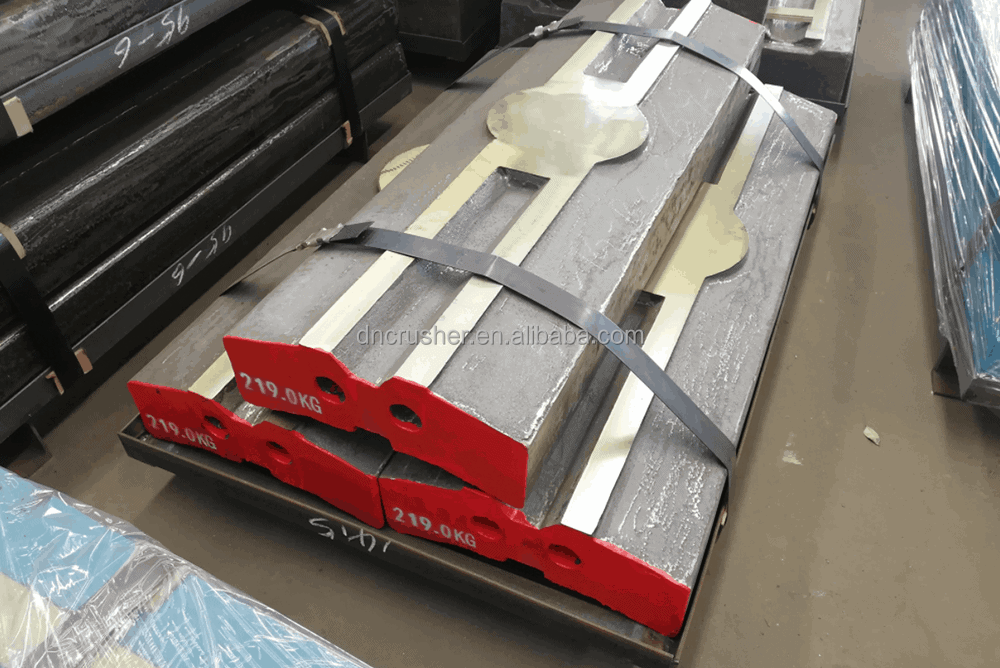

With chrome steel, the carbon is chemically bonded in the form of chromium carbide. The wear resistance of chrome steel is based on these hard carbides of the hard matrix, whereby the movement is hindered by offsets, which provides for a high degree of strength but at the same time less toughness.

To prevent the material from becoming brittle, the blow bars must be heat-treated. It must thereby be observed that the temperature and annealing time parameters are exactly adhered to. Chrome steel typically has a hardness of 60 to 64 HRC and a very low impact strength of 10 J/cm².

To prevent breakage of chrome steel blow bars, there may not be any unbreakable elements in the feed material.

MARTENSITIC STEEL

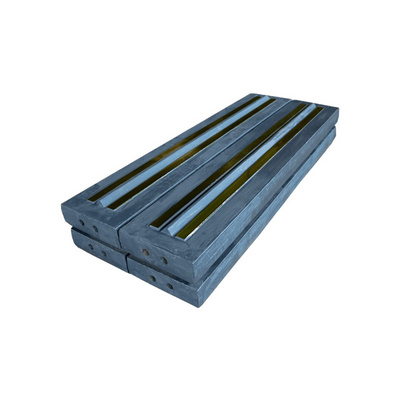

Martensite is a completely carbon-saturated type of iron that is made by quick cooling-off. It is only in the subsequent heat treatment that carbon is removed from the martensite, which improves the strength and wear properties. The hardness of this steel ranges between 44 to 57 HRC and the impact strength between 100 and 300 J/cm².

Thus, with regard to hardness and toughness, martensitic steels lie between manganese steel and chrome steel. They are used if the impact load is too little to harden the manganese steel, and/ or good wear resistance is required along with good impact stress resistance.

METAL MATRIX WITH CERAMIC COMPOSITES

Metal Matrix Composites, combine the high resistance of the metal matrix with extremely hard ceramics. Porous preforms made of ceramic particles are produced in the process. The metallic molten mass penetrates into the porous ceramic network. The experience and knowledge are particular to the casting process in which two different materials - steel with a thichness of 7.85 g/cm³ and ceramic with a thickness of 1-3 g/cm³ - are combined and there is a thorought infiltration.

This combination makes the blow bars especially wear-resistance but at the same time very impact-resistant. WIth blow bars made of composites from the field of ceramics, a service life that is three to five times as long as that of martensitic steel can be achieved.