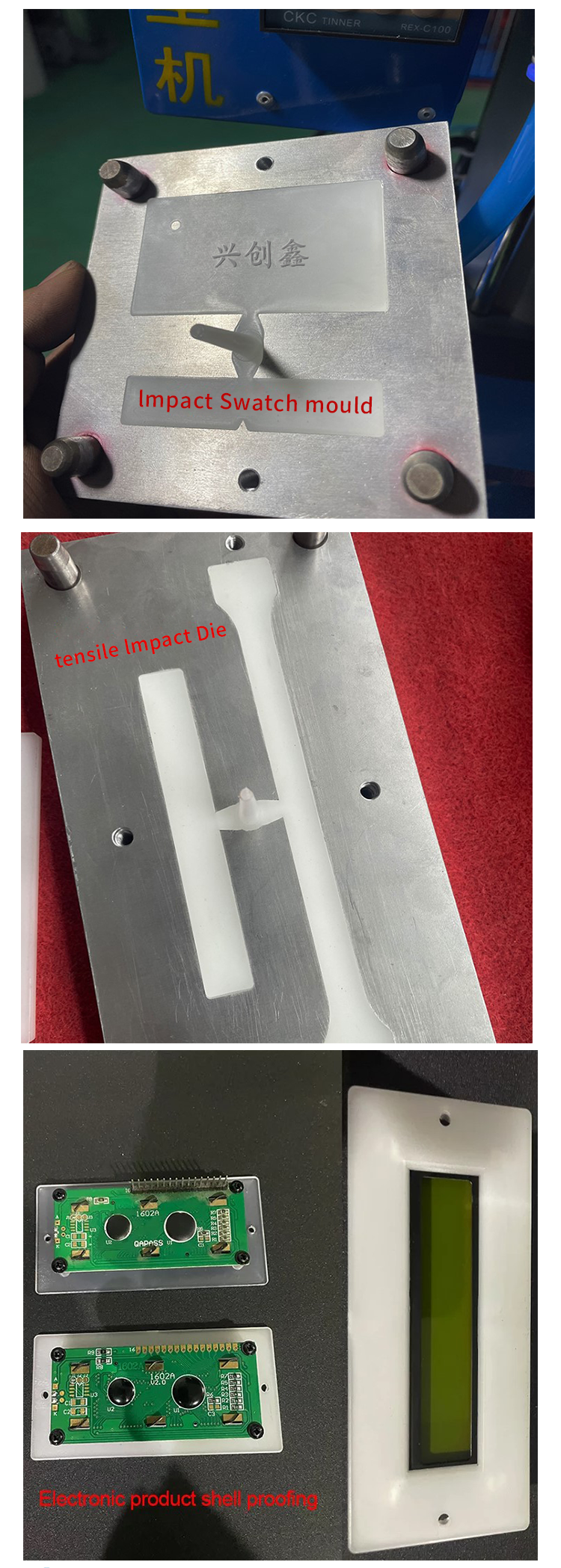

This whole machine is small in size, light in weight, easy to move and use, suitable for one molds, or multiple molds, 1-20g

product injection.The injection molding machine is pneumatically operated, compact and easy to move. Requires air pressure to

drive 0.7mp-0.8mp.Plunger, plunger sleeve and connecting screws are made of 304 stainless steel for corrosion resistance.

Injection gram weight 0-20 grams (can be customized within 50 grams, experimental swatches, rheological experiments, pigeon foot

rings, teaching experiments, small batch production, etc. Factory direct sales

product injection.The injection molding machine is pneumatically operated, compact and easy to move. Requires air pressure to

drive 0.7mp-0.8mp.Plunger, plunger sleeve and connecting screws are made of 304 stainless steel for corrosion resistance.

Injection gram weight 0-20 grams (can be customized within 50 grams, experimental swatches, rheological experiments, pigeon foot

rings, teaching experiments, small batch production, etc. Factory direct sales