NaN / 0

Shrimp Feed Making Machine Attached Free Parts Floating Fish Feed Mill Pellet Extruder Machine

Get Latest Price

US$ 7750

≥1 Sets

Quick Details

Max. Capacity:

500kg/h

Place of Origin:

Henan, China

Brand Name:

Mikim

Voltage:

380V

Product Details

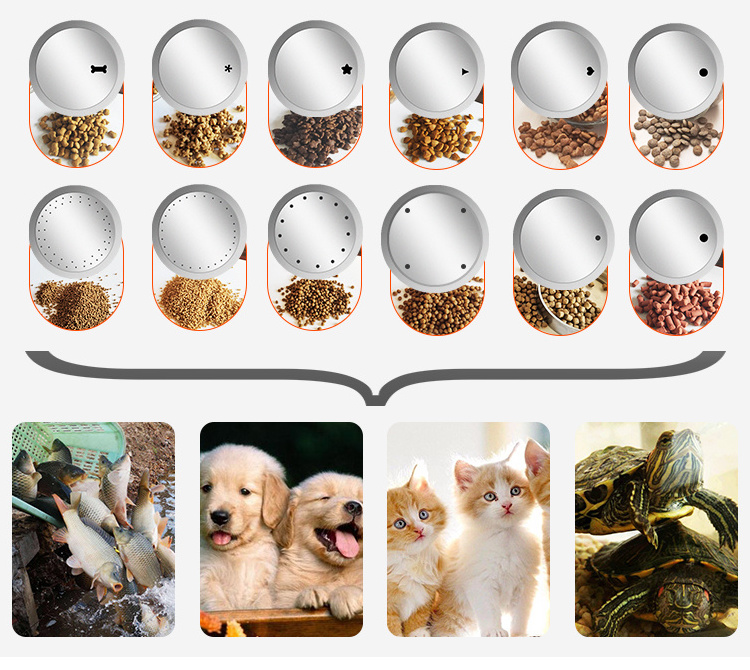

1.This machine is pellet feed extrusion equipment. Fish food, cat food, dog food and other pet feed extruder. Various patterns can be produced, and the molds can be customized according to requirements.

2. The product discharge port is equipped with frequency conversion speed control rotary cutting device, which can be arbitrarily adjusted blade speed, control cutting speed and length

3. This equipment takes corn, soybean (bean cake) and other animal scraps as raw materials, which can be directly added to the machine to produce different pellets with novel shape, unique taste, rich nutrition and fine organization. Suitable for dogs, cats, fish, birds, rabbits, shrimps, etc.

4. If the raw material is in powder form, it can be made into granule directly; if the raw material is in granule form, it should be crushed into powder less than 3mm first.

5. Raw material moisture also has certain requirements, if less than 30%, it is better.

The feed extruder can produce all kinds of feed pellets: pet feed, aquatic feed, etc., such as: cat food, dog food, fish feed, all kinds of fish bait, nesting material, floating feed, submerged feed, 1-20 mm pellet feed.

Suitable for farmers, small and medium-sized feed mills and scientific research institutions. The extruded feed particles produced by this machine are neat and smooth.

|

Model

|

40

|

60

|

70

|

80

|

|

Power

|

5.5KW

|

15KW

|

18.5KW

|

22KW

|

|

Yield

|

120-150

|

180-220

|

240-300

|

400-500

|

|

Weight

|

350KG

|

450KG

|

500KG

|

580KG

|

|

Size(mm)

|

1500*1100*1100

|

1600*1300*1250

|

1600*1300*1250

|

1800*1400*1350

|

|

Model

|

100

|

120

|

135

|

160

|

|

Power

|

37KW

|

55KW

|

75KW

|

90KW

|

|

Yield

|

700-1000

|

1200-1500

|

1500-1800

|

2000-2400

|

|

Weight

|

750KG

|

850KG

|

950KG

|

1200KG

|

|

Size(mm)

|

1970*2900*1150

|

2200*2900*1200

|

2350*2900*1200

|

2350*2900*1400

|

Product features

1. Sleek design, compact structure, high productivity. High efficiency and low energy, cost saving.

2. Equipped with multiple sets of heating plates, fast warming and good puffing effect.

3. After puffing, the taste of the feed is improved and the fragrance of the feed ingredients is increased.

|

Model

|

45

|

65

|

75

|

85

|

|

Power

|

5.5KW

|

15KW

|

18KW

|

22KW

|

|

Yield

|

140-160

|

200-240

|

260-320

|

450-550

|

|

Weight

|

350KG

|

500KG

|

550KG

|

750KG

|

|

Size(mm)

|

1800*810*1080

|

1700*970*1240

|

1700*970*1240

|

1850*1070*1400

|

1.Control box control the whole production line operation, the whole machine can be operated by one person

2. Put the raw materials into the mixing machine, add the proportion of water, mixing and stirring evenly.

3. Send the stirred raw materials to the hopper of feed puffer through screw elevator for puffing.

4. The feed puffing machine for puffing granulation, puffed semi-finished products of uniform size, full of grains.

5. Puffed semi-finished products are sent to the multi-layer drying box through pneumatic conveyor for drying.

6. The dried semi-finished products will be conveyed to the roller seasoning machine by pneumatic conveying machine for oil seasoning, and then can be packed and sold.

Welcome to contact us

These production lines can be equipped with the right model according to your needs.

FAQ

Q:What is the quality? Easy to use? What is the effect?

A: 1.Improve feed utilization: Because the fish feed expander can make the feed expand under high temperature and pressure, the expanded feed is easily digested and absorbed by the fish, which can improve the feed utilization of fish.

2.Improve feed quality: the expanded feed particles are of uniform size and moderate density, which can reduce feed waste and pollution and improve feed quality.

3.Improve production efficiency:Fish feed expanding machine can realize automatic production, greatly improve the production efficiency, reduce labor costs.

4.Energy saving: Fish feed expanding machine adopts advanced heating and expanding technology, which can save energy and reduce emission and meet the requirements of environmental protection.

5.Strong adaptability:Fish feed expanding machine can be adapted to the production of different types, shapes and flavors of feeds, which can meet a variety of breeding needs.

Q:Don't know what material to process feed?

A: Corn, soybean (soybean cake) animal scraps as raw materials, directly added to the machine to produce different particles of novel shape, unique taste, rich in nutrients, fine texture, suitable for dogs, cats, fish, birds, rabbits, shrimp, dogs, cats, mink, foxes and other different flavors of feed.

Q: What is the scope of application?

A It is suitable for professional farmers, small and medium-sized feed mills and scientific research institutions. In the case of the same feed formula, homemade puffed feed costs 60% -80% lower than the market price; the machine produces puffed feed particles neat, smooth, floating surface for more than 12 hours does not sink, does not pollute the water supply, sterilization to reduce fish disease, puffed particles of the size, length and shape can be adjusted at will. Is it easy to operate? Is the quality guaranteed? The machine is easy to operate, low noise, one button start, convenient and quick. The motor is guaranteed to be pure copper wire, if you have any questions, please contact us directly 24 hours online guidance, professional technicians to answer questions, attentive after-sales service.