NaN / 0

M10 Safety Nut Anti theft fasteners Factory Outlet Stainless Steel nut Customized groove type

Get Latest Price

US$ 0.43

≥300 Pieces

Quick Details

Finish:

passivated

Measurement system:

Metric

Application:

Heavy Industry, Mining, Automotive Industry

Place of Origin:

Guangdong, China, Guangdong,china

Product Details

Specification

|

item

|

value

|

|

Place of Origin

|

Shenzhen

|

|

Brand Name

|

JINGBANG

|

|

Model Number

|

Anti-theft nut

|

|

Place of Origin

|

Guangdong,china

|

|

Model Number

|

Steel Safety Nut Tamper Proof Nut

|

|

Material

|

Stainless steel or customized

|

|

Size

|

M5 M6 M8 M9 M10 M12 1/4-20 5/16-18 3/8-16 or customized

|

|

Standard

|

DIN

|

|

Surface treatment

|

Zinc plated, Anodizing, Black oxide

|

|

Processing

|

CNC Maching

|

|

Sample

|

Free samples

|

|

Delivery time

|

Spot goods for 3-7 days

|

|

Quality Control

|

100% full inspection

|

Product Description

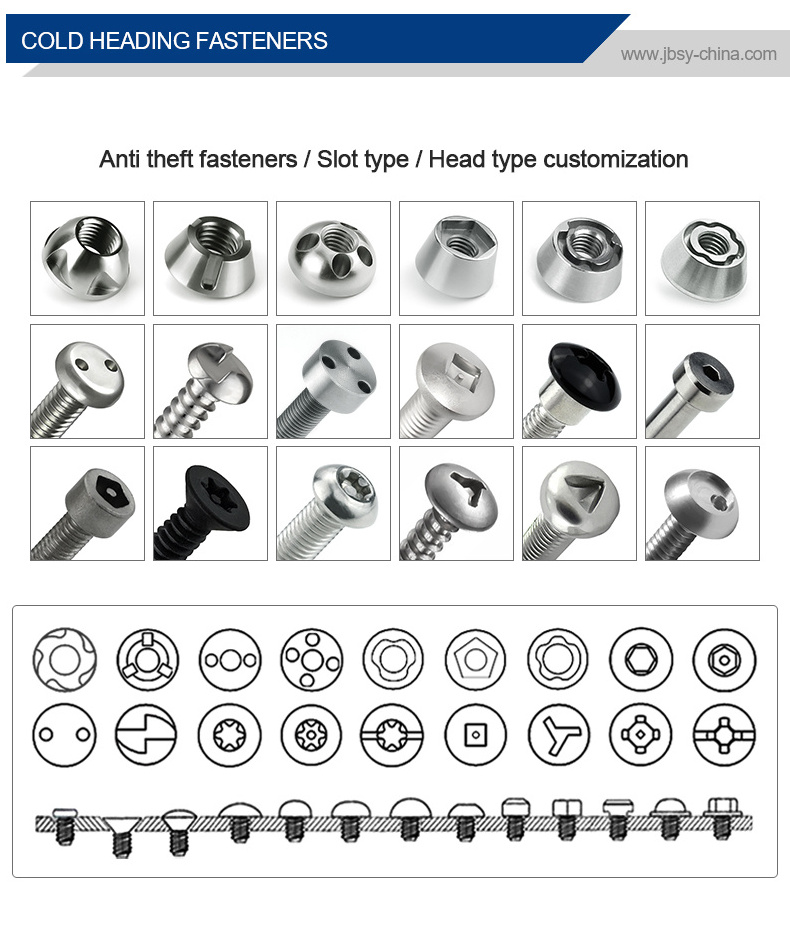

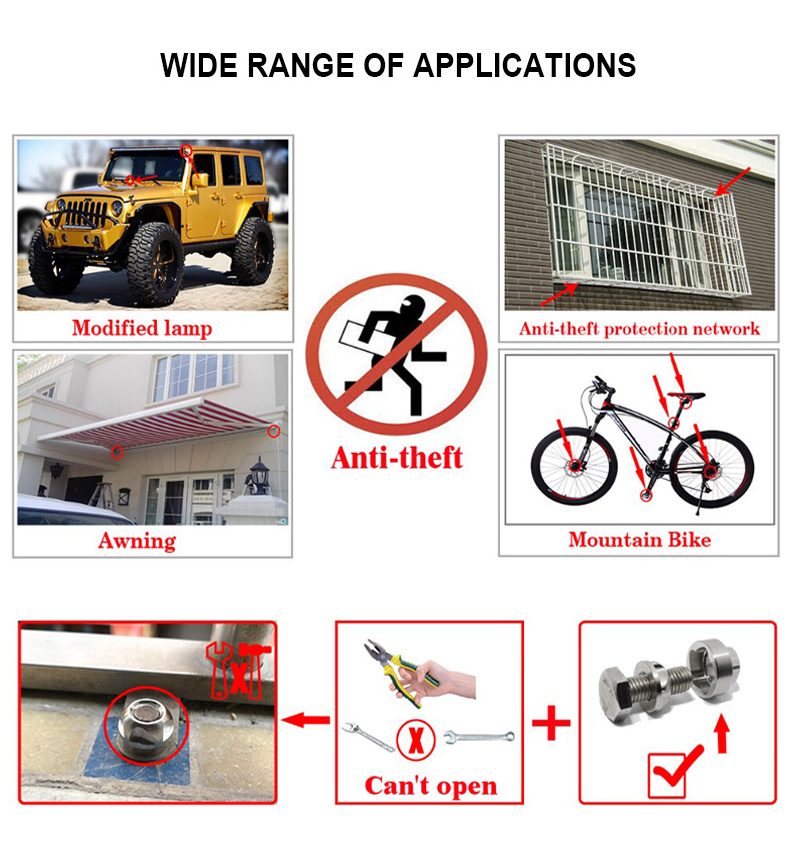

The fastening and opening of bolts and nuts adopts non-standard design, and the matching non-standard tools are used to solve the opening and fastening problems. In general, other wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting, opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting metal. It is a processing method that utilizes the plastic deformation of metal under the action of external forces, and with the aid of molds, redistributes and transfers the volume of metal to form the required parts or blanks. The cold heading process is most suitable for producing standard fasteners such as bolts, screws, nuts, rivets, and pins.etc

Jingbang started manufacturing industrial components in 2005 and began selling metal parts to Europe and the United States in 2012.The founder (DENG) and his team deeply love the parts manufacturing work they are engaged in. Compared to the history of industrial manufacturing, we are a very young team, but we are confident that we can better apply Chinese made industrial parts to more fields.We are linked to our customers through "bolts" and "nuts", and we are honored to serve distributors from 40 countries and customers from different industries.We will continue to use our attitude and methods to provide our customers with higher quality metal components.

We have two manufacturing factories located in Shenzhen and Sichuan .Our Shenzhen factory covers an area of 3000 square meters, mainly engaged in CNC lathe processing and CNC milling machines processing, they can quickly validate and better showcase our design to our customers.Our Sichuan factory covers an area of 15000 square meters, mainly engaged in mold development and cold heading processing,forging processing, CNC lathe processing, CNC milling machine processing, they can make the original complex product processes become simpler and more reliable.We can flexibly allocate the manufacturing site for our customers' products according to their order requirements.

Our QC testing team is equipped with tensile machines, hardness machines, 2D/3D measurements, project measurements, blue light scanning, coating thickness, vernier calipers, outside micrometers, hardness meters, salt spray machines, and other testing equipment to ensure the quality of our products