NaN / 0

self leveling urethane expansion joint sealant Airport Runway Joints Concrete Road Joints Sealing

Get Latest Price

US$ 1.73

≥1000 Pieces

Quick Details

CAS No.:

9016-00-6

Other Names:

expansion joint filler

Place of Origin:

Henan, China

Brand Name:

RALEAD

Product Details

Products Description

Road and Bridge Expansion Joint Sealant Filler

A fast-curing, one part flexible sealant designed to provide effective sealing of construction and expansion joints on concrete,stone, brick and other surfaces. This solvent-free material is a cost-effective and high performance alternative to conventional mastics and sealants, providing joints with up to 25% flexibility and outstanding weather and chemical resistance. It does not equire any hot work and cures quickly, ensuring a safe and easy application

Product Features

1,Provides expansion joint flexibility of up to 25%

2, Downtime reduction due to its fast-curing properties

3,Reduced future maintenance and eliminates the need for expensive structural rebuild

4,Reduced health and safety risks as it is solvent-free

5,Application and cure at room temperature - no hot work involved

6, Excellent weather and chemical resistance against a wide range of chemicals

7,Easy to mix and apply manually with no specialist tools required

8,Excellent adhesion to surfaces including concrete, brick, stone and steel

2, Downtime reduction due to its fast-curing properties

3,Reduced future maintenance and eliminates the need for expensive structural rebuild

4,Reduced health and safety risks as it is solvent-free

5,Application and cure at room temperature - no hot work involved

6, Excellent weather and chemical resistance against a wide range of chemicals

7,Easy to mix and apply manually with no specialist tools required

8,Excellent adhesion to surfaces including concrete, brick, stone and steel

9,Single-component packaging, easy to use, and good extrudability within the usual construction temperature range;

10, No primer is required, it is chemically compatible with concrete, and has a firm chemical bond to concrete;

11,Excellent aging resistance, will not be damaged by sunlight, rain, snow, ultraviolet rays, and ozone; excellent resistance to high and low temperatures, and the cured adhesive strip has excellent performance at -40°C to 120°C;

12,High displacement ability: With the expansion and shear deformation of the concrete joints, the colloid itself will not be destroyed;

13,Low modulus: low stress generated during passive deformation to ensure that the concrete surface is not damaged;

14, High elastic recovery ability: It can reciprocate and follow the seam movement, fast response, quick recovery, and small permanent deformation.

10, No primer is required, it is chemically compatible with concrete, and has a firm chemical bond to concrete;

11,Excellent aging resistance, will not be damaged by sunlight, rain, snow, ultraviolet rays, and ozone; excellent resistance to high and low temperatures, and the cured adhesive strip has excellent performance at -40°C to 120°C;

12,High displacement ability: With the expansion and shear deformation of the concrete joints, the colloid itself will not be destroyed;

13,Low modulus: low stress generated during passive deformation to ensure that the concrete surface is not damaged;

14, High elastic recovery ability: It can reciprocate and follow the seam movement, fast response, quick recovery, and small permanent deformation.

Main Applications

Expansion joints sealing on horizontal surfaces such as floors, bridges, roadways, car parks and airport pavement

Sealing and filling for

repairing of concrete crack

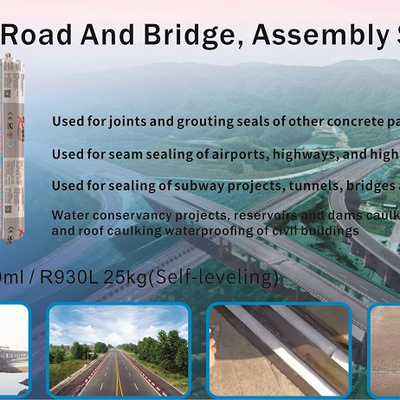

1. Used for seam sealing of airports, highways, and high-speed rail lines.

2. Used to seal the joints and grouting joints of other concrete pavements.

3. Used for sealing of subway projects, tunnels, bridges and other projects.

4. Used for caulking and waterproofing of water conservancy projects and reservoir dams.

5. Used for roof caulking waterproofing of industrial and civil buildings.

2. Used to seal the joints and grouting joints of other concrete pavements.

3. Used for sealing of subway projects, tunnels, bridges and other projects.

4. Used for caulking and waterproofing of water conservancy projects and reservoir dams.

5. Used for roof caulking waterproofing of industrial and civil buildings.

|

Main chemical composition

|

Modified Silane

|

|

|

|

Model

|

R930

|

R930L

|

|

|

Appearance

|

Gray paste

|

Gray self-leveling

|

|

|

Sag(mm)

|

0

|

/

|

|

|

Extrudability(ml/min)

|

200

|

400

|

|

|

Surface drying time (min)

|

40

|

45

|

|

|

Elongation at break (%)

|

900

|

1000

|

|

|

Tensile strength (Mpa)

|

≥1.0

|

|

|

|

Elastic recovery rate (%)

|

≥80

|

|

|

|

Tensile modulus (MPa)

|

≤0.4

|

|

|

|

Fixed-stretch cohesiveness

|

No damage

|

|

|

|

Thermal weight loss (%)

|

3

|

|

|

|

Cracking, chalking

|

No

|

|

|

Meet the standard JC/T 976-2005 "Road and Bridge Caulking Sealant"

Civil Aviation Standard MH5006-2002 "Code for Construction of Airport Concrete Pavement"

Traffic standard JT/T589-2004 "Concrete pavement caulking sealing material"

American Standard ASTM C ASTM D 5893-04

Civil Aviation Standard MH5006-2002 "Code for Construction of Airport Concrete Pavement"

Traffic standard JT/T589-2004 "Concrete pavement caulking sealing material"

American Standard ASTM C ASTM D 5893-04

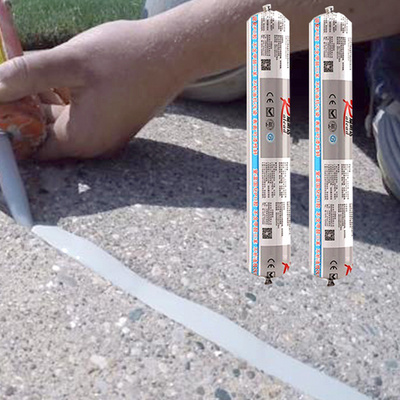

Operation Process

1. Cutting the construction joint: use a cutting machine to cut the construction joint according to the specifications, use a blow dryer, brush, spatula and other tools to remove the dust and sundries in the joint, and let it dry fully; in order to improve the bonding strength, brush the primer.

2. Laying cushion material: Lay a polyethylene foam strip that is slightly larger than the gap in the seam, with a depth of 8mm or more.

3. Glue filling liquid: Put the self-leveling glue into the filling equipment, insert the hose into the bottom of the seam and inject the caulking glue into the seam; put the paste-like glue into the glue gun, the glue nozzle goes deep into the gap, squeeze the glue and smooth it.

4. Leave a gap: Because the gap will expand and contract with heat, the surface of the caulking glue should be about 2mm lower than the road surface after construction.

5. Curing for at least 5 hours after construction, and the period of loss of adhesion will be exceeded.

2. Laying cushion material: Lay a polyethylene foam strip that is slightly larger than the gap in the seam, with a depth of 8mm or more.

3. Glue filling liquid: Put the self-leveling glue into the filling equipment, insert the hose into the bottom of the seam and inject the caulking glue into the seam; put the paste-like glue into the glue gun, the glue nozzle goes deep into the gap, squeeze the glue and smooth it.

4. Leave a gap: Because the gap will expand and contract with heat, the surface of the caulking glue should be about 2mm lower than the road surface after construction.

5. Curing for at least 5 hours after construction, and the period of loss of adhesion will be exceeded.

Packaging specification

R930 uses aluminum film: 600ml/pcs, 20pcs/carton

R930L uses plastic barrel: 25kg/barrel

R930L uses plastic barrel: 25kg/barrel

Certifications

R & D

In the field of adhesives, we are not only a manufacturer, but also a total solution provider covering bonding, sealing and potting processes.

Since its establishment, our company has always adhered to the scientific development concept, and regards technology research and development and personnel training as the company's development goals. Our company has set up a special technical research and development department, and has a technical research and development team with high education, rich experience and strong innovation ability. The company has 6 senior engineers, 4 intermediate engineers and 10 professional technicians, with an average age of about 40 years old. The company pays attention to the recruitment and training of talents. The company recruits technical R&D personnel for a long time and continuously enriches the R&D team. At the same time, the company regularly conducts professional training for existing talents, and also arranges organizations to observe and study in other enterprises, so as to continuously improve the professionalism of R&D personnel. knowledge and innovation. The company also attaches great importance to the research and development of new products. Every year, it invests a lot in the research and development of new products and has achieved great results.

Exhibition

Hot Searches