NaN / 0

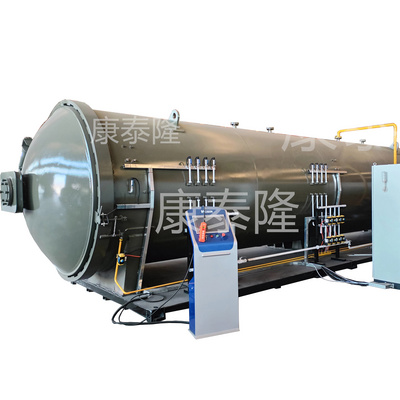

Automatic Composite Material Pressure Vessel High Quality Composite Curing Autoclave Price Composite Autoclave For Sale

Get Latest Price

US$ 5000

≥1 Pieces

Quick Details

Volume (m³):

as per the dimension

Max Working Pressure(MPa):

1.7MPa

Place of Origin:

Zhejiang, China

Brand Name:

custom

Product Details

Product Description

autoclave for carbon fiber

EQUIPMENT FEATURES

1. PID control, most accurate

2. Electrical Curing recommended (Far-infrared heating internative)

3. Water cooling system

4. Air cycle system

5. Meet CE International Standard

APPLICATION SCOPE

Composite material processing. Carbon fiber, boron fiber, aramid fiber, glass fiber, metal composites, reinforced plastics and etc..

Widely used in aircraft, missiles, satellites and space shuttle, such as the airplane cabin door, fairing, airborne radar cover, the plane bracket, empennage.

Autoclave Characters :

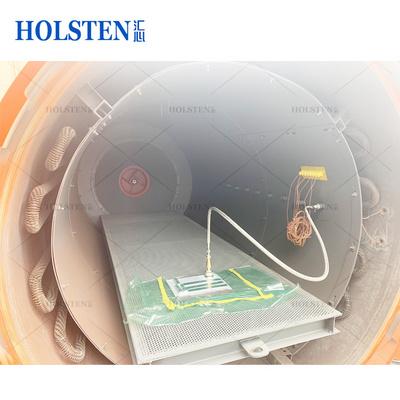

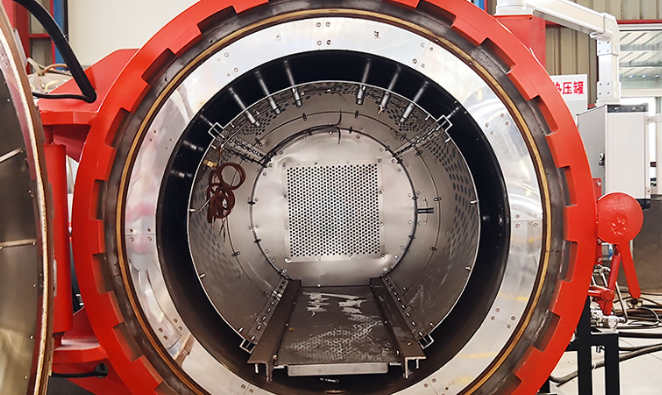

1. Electric curing ensure effective heating all around the interior chamber

2. Motor fans make air evenly circulation for temperature distribution better

3. Double channel PLC /PID control system, alternative control channel guarantee the presetted

process progressive while the autoclave accident happens.

4. Vacuum port connect with the vacuum bags pressure, control and detecting independent.

5. Interior air circulation system

6. Chamber and motor cooling system

7. Auto door leaf with oil cylinder control

8. Each vacuum port independent control and detecting

9. Temperature ,pressure and time pre-setted and adjustable

10. Interior and outside Insulation

Autoclave specification need to confirm with you, diameter ,length ,pressure ,temperature ect

Related Products