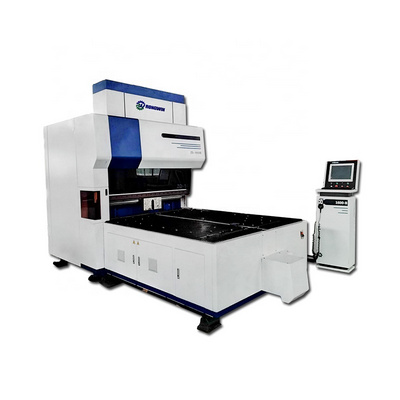

bending machine. The high-strength frame and simple torsion bar structure ensure the synchronization of both ends of the press brake and the smooth operation of the ram. The internal of the oil cylinder adopts the method of precise screw nut adjustment to realize the adjustment of bending angle. Advanced ball screw and linear guide roller back gauge are driven and positioned by servo motor.

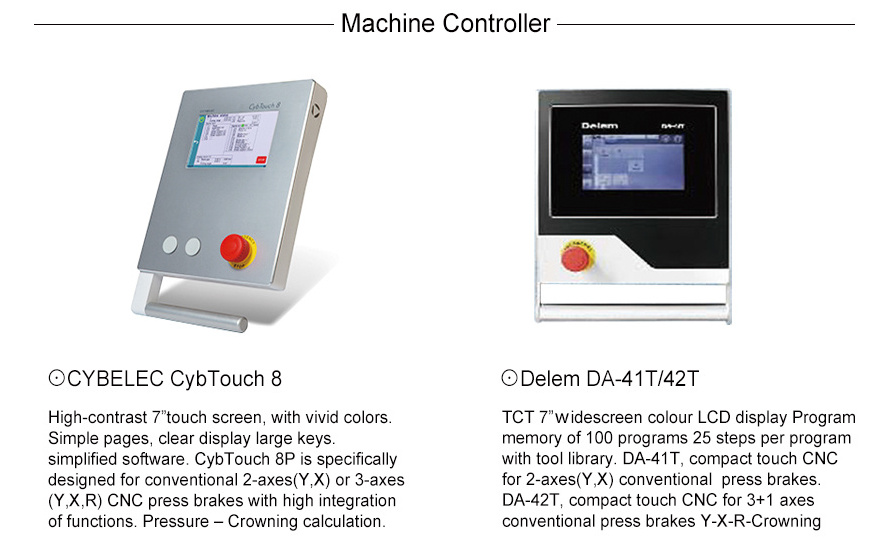

It can bring stable bending performance. High quality hydraulic system can burst out strong power and bending speed. Powerful well-known brand CNC controller can edit bending angle and positioning size. Multi part bending, avoidance and correction functions.

Affordable price is a very good choice for normal bending workpieces.

30T ~ 400T optional.