the motor brand can be chosed according to your requirement for example domestical brand,ABB or Siemens

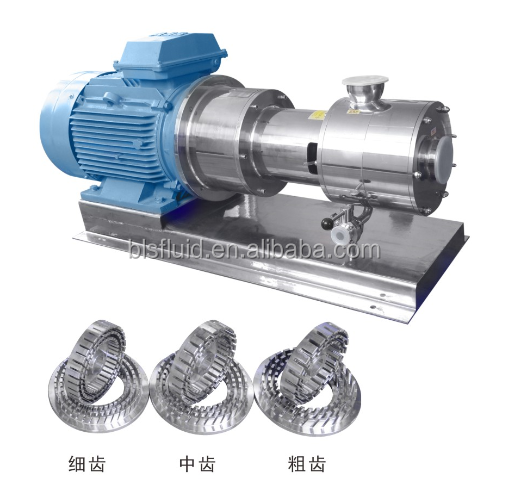

Stainless steel In line high shear homogeneous /homogenizer/emulsifying pump

Operation Principle :

Three sets of stators and rotors are equipped in wo rKing cavity. Driving shaft in working cavity is an arm, electrical motor and the shaft in bearing cabinet can be connected by spring couphng to improve the operation quality of driving shaft .

Seal form can be selected In different conditions. it is it for middle-iarge scale on-line continuous production or circulated treatment production process.

|

Product Name:

|

in-line mixer

|

|

Description:

|

Designed according to GMP standard, widely used for transfer viscous media in the food-processing, cosmetics.

|

|

Construction:

|

3 stage rotor and Stator series(CNC treatment)

|

|

Material:

|

SS304/SS316L

|

|

Flow range:

|

0-130T/H

|

|

Outlet Pressure:

|

≤0.2 MPa.

|

|

Speed:

|

2800-2900 rpm (Frequency Converter Control can be choose)

|

|

Rotor Type:

|

teeth

|

|

Teeth space:

|

2.2kw 4mm; > 2.2kw 6mm

|

|

Rotor and stator space:

|

Standard 0.5mm(optional 0.25mm-0.5mm)

|

|

Motor power:

|

1.5kw, 2.2kw, 4kw, ...75KW

|

|

Sealing option:

|

Sanitary single mechanical seal/Dual End Mechanical Seal

|

|

Seal material:

|

FKM

|

|

Max feeding medium viscosity:

|

< 3000CPs

|

|

Voltage:

|

110-480V, 50hz/ 60hz

|

|

Bearing:

|

Japanese NSK

|

|

Motor:

|

Siemens, ABB, LOCAL etc.

|

|

Surface treatment:

|

Inner polished and Sandblast outside

|

|

Available connection:

|

Clamp, Union, Flange etc.

|

|

Available standard:

|

DIN, SMS, 3A, RJT, ISO/IDF

|

|

Operated:

|

Electric

|

|

Application scope:

|

Dairy, food, beverage, cosmetic, etc

|

|

Packaging Details:

|

Plywood case Or as per the request of customers

|

the motor brand can be chosed according to your requirement for example domestical brand,ABB or Siemens

cooling water connection port to cool down the mechanical seal

trolley to move the machine easily,you can choose to install it or not

Bailishi High-Speed Shearing emulsification pump is a new product researched and developed by our company after assimilatingforeign advanced techniques and processes.